Manufacturing method for spiral cooling water jacket sand mold

A technology of cooling water jacket and manufacturing method, which is applied in the field of casting, can solve the problems of complex mold structure and low efficiency of sand core molding, and achieve the effect of simple mold structure, large-scale production requirements, and low sand injection pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A method for manufacturing a spiral cooling water jacket sand mold, the method comprises the following steps:

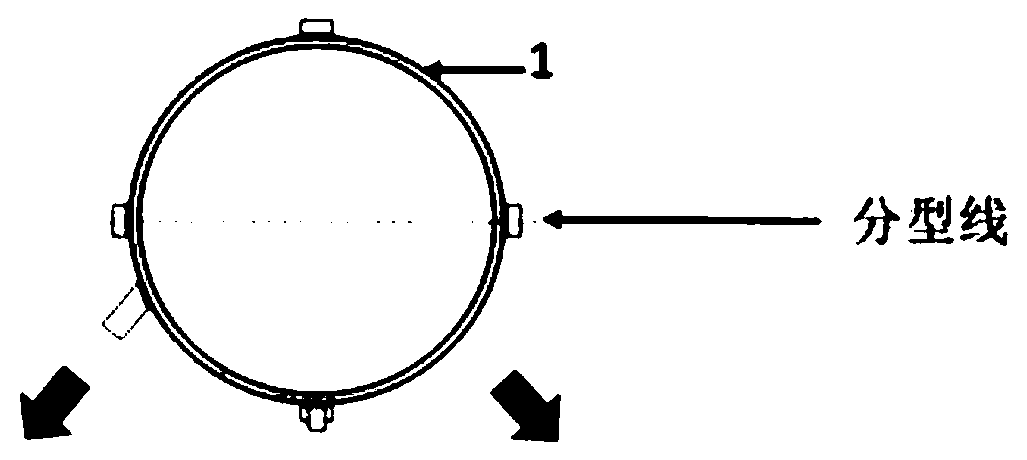

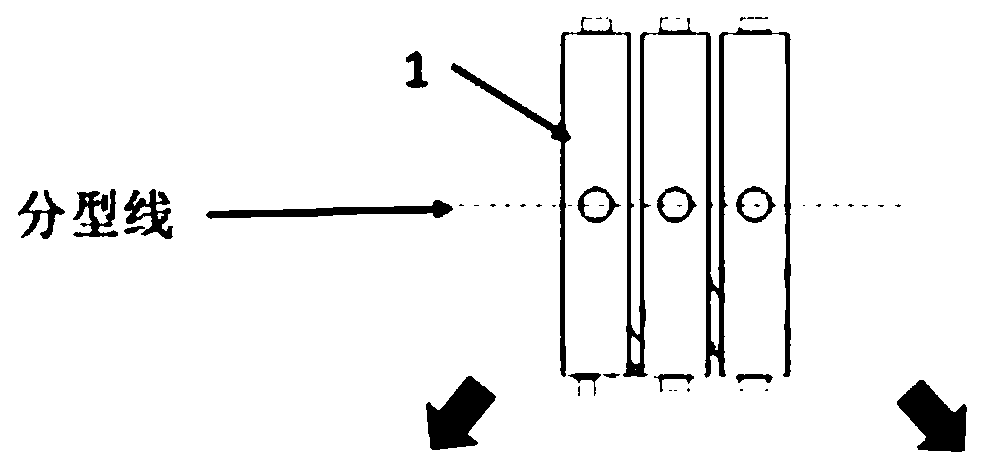

[0025] Refer to Figure 1— Figure 5 ,, Step 1: Divide the cylindrical water jacket forming body 1 into two 180° semicircular sand cores 2 for sand molding respectively; In the process, the pressure loss of sand shooting is low, the density and strength of the forming part are good, and the mold does not need a side pumping structure, which reduces the complexity of the mold.

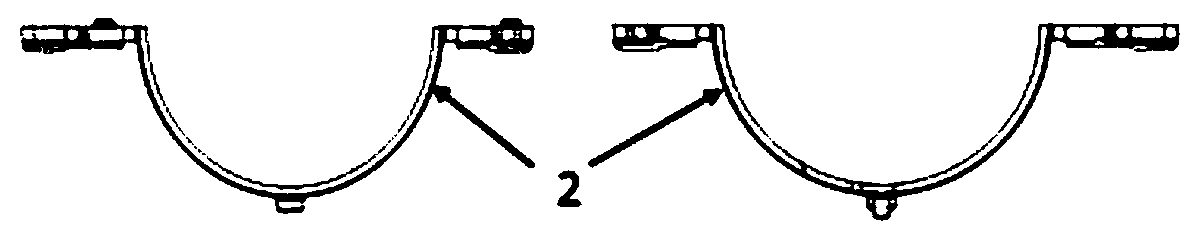

[0026] Step 2: Add reinforcing ribs 3 to both ends of the semicircular sand core 2 to make the entire core part into a square frame structure, and then use a simple special mold to bond and fix it; the purpose of adding reinforcing ribs 3 is not only It is to increase the strength of the sand core and also increase the plane for the water jacket sand core, so that the ejector rod can push the water jacket sand core out. Because the spiral wall is too thin, the sand core will leak if it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com