Arc-shaped core-pulling structure for mold

A core-pulling structure and arc-shaped technology, used in home appliances, other home appliances, applications, etc., can solve problems such as core-pulling stuck, inclined guide post fracture, and inability to mass-produce, reducing force loss and improving stability. Motion, effect of reducing transfer steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

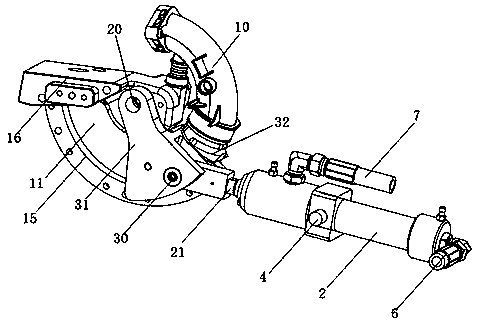

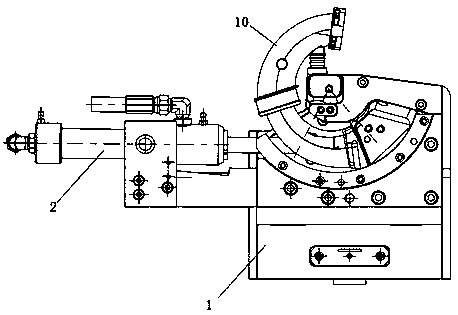

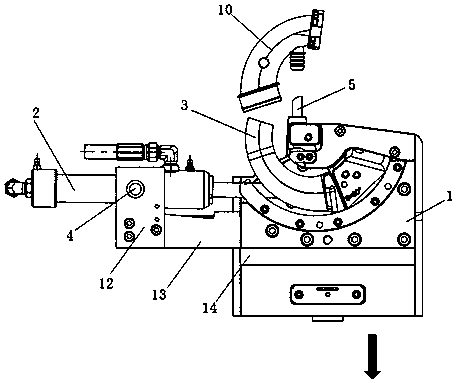

[0018] Such as Figure 1 to Figure 3 As shown, the arc-shaped core-pulling structure of a mold in this embodiment includes a large slider 1, an autorotation cylinder 2 and a rotary insert 3, the autorotation cylinder 2 is arranged on the large slider 1, and the autorotation cylinder and the large slider Connected by the shaft 4. The large slider 1 has an arc-shaped accommodation chamber 11 , and the rotating insert 3 is arranged in the arc-shaped accommodation chamber 11 and pivotally connected with the large slider 1 . The self-rotating oil cylinder 2 has a telescopic shaft 21 which is pivotally connected with the rotary insert 3 . In the above technical solution, the rotary insert can be rotated in the arc-shaped accommodation chamber 11 by being pushed by the telescopic sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com