Sheet metal forming method of multi-deep-cavity thin-wall part of aircraft

A technology of thin-walled parts and forming method, applied in the field of aircraft parts processing, can solve the problems of low processing efficiency, affecting the surface quality of parts, uneven material flow, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The present embodiment provides a sheet metal forming method for multi-deep cavity aircraft thin-walled parts, comprising the following steps:

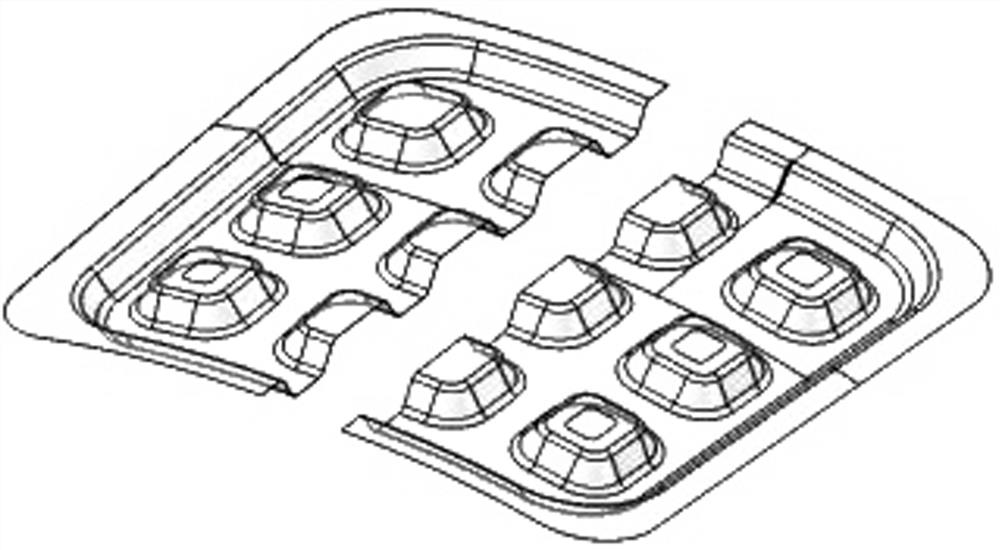

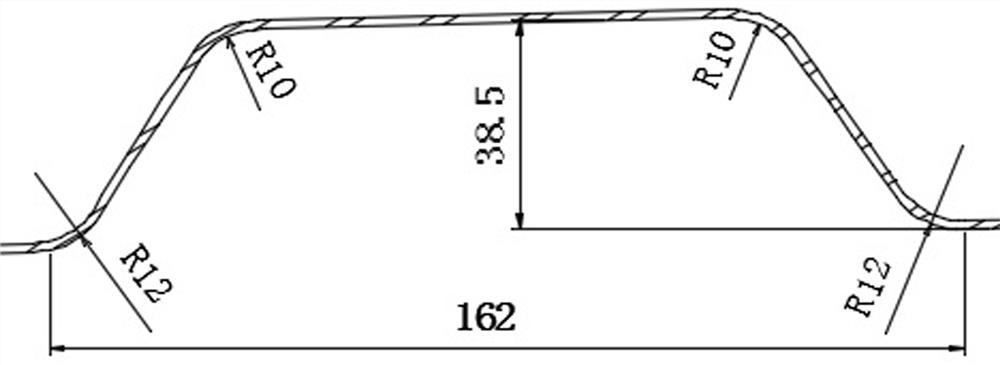

[0034] (1) Obtain the 3D digital model of the part according to the part forming process plan, so as to determine the type of deep cavity of the part and the size of the standard deep cavity; the 3D digital model of the part with deep cavity is as follows figure 1 Shown, standard deep cavity dimensions, such as figure 2 shown;

[0035] (2) According to the size of the deep cavity of the part, manufacture spherical deep drawing dies, deep drawing dies, and integral deep drawing dies;

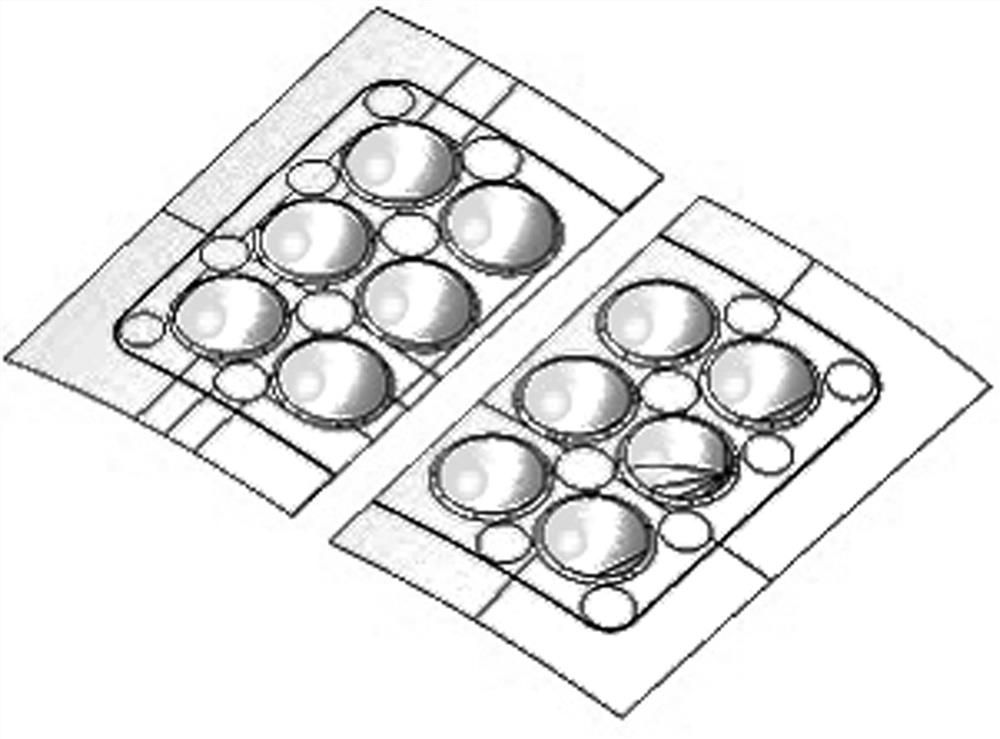

[0036] (3) Use a spherical deep drawing die to draw the part to be processed into a deep cavity into a hemispherical shape to form a part with a spherical deep cavity; the structure diagram of a part with a spherical deep cavity, such as image 3 As shown, the size diagram of the spherical deep cavity, such as Figure 4 shown;

[0037] (4) Us...

Embodiment 2

[0041] On the basis of the above-mentioned embodiments, this embodiment further defines the types of deep cavities of parts, such as Figure 6 , Figure 7 As shown, in the step (1), the types of the deep cavity of the part include fully enclosed deep cavity and semi-closed deep cavity. When the fully enclosed deep cavity is drawn, the mold needs to fully cover the deep cavity, and When drawing the semi-closed deep cavity, the opening does not need a mold to cover the deep cavity. For the semi-closed deep cavity, the opening part should be transitioned according to the slope to facilitate the flow of materials. Other parts of this embodiment are the same as those of the foregoing embodiment, and will not be repeated here.

Embodiment 3

[0043] This embodiment further defines the process of step (3) on the basis of the above embodiments. In the step (3), the ratio of the surface area of the standard deep cavity to the spherical area of the drawn hemispherical deep cavity is 1:1.02 ~1.08. Since other parts of this embodiment are the same as those of the foregoing embodiment, details are not repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com