A kind of manufacturing method of tantalum capacitor that improves the porosity of anode block

A technology of tantalum capacitors and manufacturing methods, which is applied in the direction of capacitors, electrolytic capacitors, circuits, etc., can solve the problems of increased difficulty in production process control, ineffective effects, and deterioration of electrical parameters of tantalum capacitors, so as to achieve easy control, ensure performance indicators, The effect of increasing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

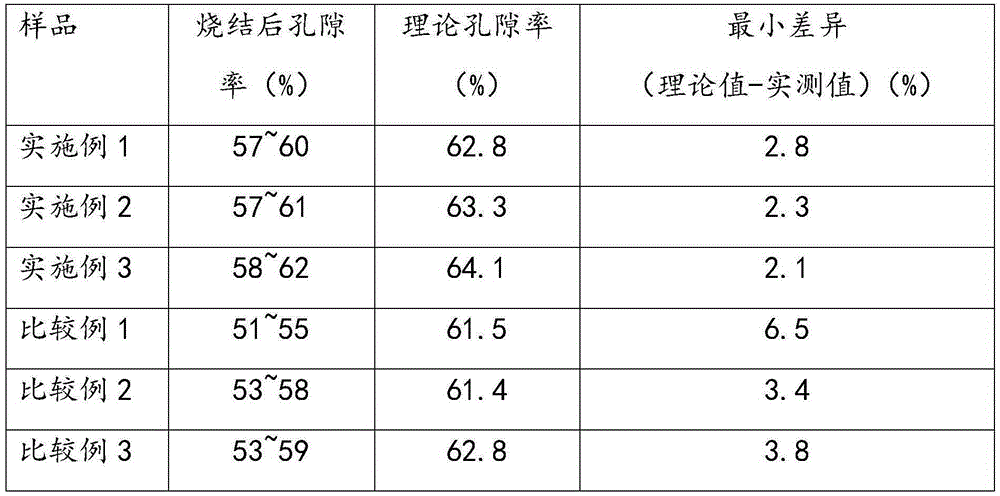

Examples

Embodiment 1

[0014] A method for manufacturing tantalum capacitors that increases the porosity of the anode block, using tantalum powder with a CV value of 150,000 μF.V / g to press into a powder with a weight of 12 mg and a size of 1.0x1.2x1.8mm 3 Taking the tantalum block as an example, it consists of the following steps:

[0015] (1), making a pore-opening agent, including: (a), putting polyvinyl alcohol with a degree of polymerization of 1200 into a glass container and adding deionized water to dissolve; (b), stirring with a magnetic stirrer while heating in a water bath to make The temperature was raised to 90°C until the polyvinyl alcohol was fully dissolved, and then continued to stir for 10 minutes; (c), the solution was filtered and allowed to stand for 24 hours, then put into a drying oven and dried at 100°C for 24 hours to obtain solid polyvinyl alcohol powder, The polyvinyl alcohol powder type cell opener obtained by crushing and screening;

[0016] (2), powder mixing, including...

Embodiment 2

[0020] A method for manufacturing a tantalum capacitor that increases the porosity of the anode block, using tantalum powder with a CV value of 100,000 μF.V / g to press it into a powder with a weight of 18 mg and a size of 0.82x2.0x2.0mm 3 Take the tantalum block as an example, it contains the following steps:

[0021] (1), making a pore-opening agent, including: (a), putting polyvinyl alcohol with a degree of polymerization of 1200 into a glass container and adding deionized water to dissolve; (b), stirring with a magnetic stirrer while heating in a water bath to make The temperature was raised to 90°C until the polyvinyl alcohol was fully dissolved, and then continued to stir for 10 minutes; (c), the solution was filtered and allowed to stand for 24 hours, then put into a drying oven and dried at 100°C for 24 hours to obtain solid polyvinyl alcohol powder, The polyvinyl alcohol powder type cell opener obtained by crushing and screening;

[0022] (2), powder mixing, comprisin...

Embodiment 3

[0026] A method for manufacturing a tantalum capacitor that increases the porosity of an anode block, comprising the following steps:

[0027] (1), making a pore-opening agent, including: (a), putting polyvinyl alcohol with a degree of polymerization of 1200 into a glass container and adding deionized water to dissolve; (b), stirring with a magnetic stirrer while heating in a water bath to make The temperature was raised to 90°C until the polyvinyl alcohol was fully dissolved, and then continued to stir for 10 minutes; (c), the solution was filtered and allowed to stand for 24 hours, then put into a drying oven and dried at 100°C for 24 hours to obtain solid polyvinyl alcohol powder, The polyvinyl alcohol powder type cell opener obtained by crushing and screening;

[0028] (2), powder mixing, comprising: (a), take by weighing 100g of tantalum powder, respectively weigh polyvinyl alcohol powder type pore opening agent and lubricant of 0.4% (that is, 0.4g) of tantalum powder wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com