Preparation method of Al5Ti1B intermediate alloy

A master alloy and prefabricated block technology, which is applied in the field of preparation of Al5Ti1B master alloy, can solve the problems of decreased yield of Ti, decreased yield of Ti and B elements, uneven heat release, etc., to eliminate elongated structure, reduce Fluoride salt by-products, the effect of reducing oxidation burning loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

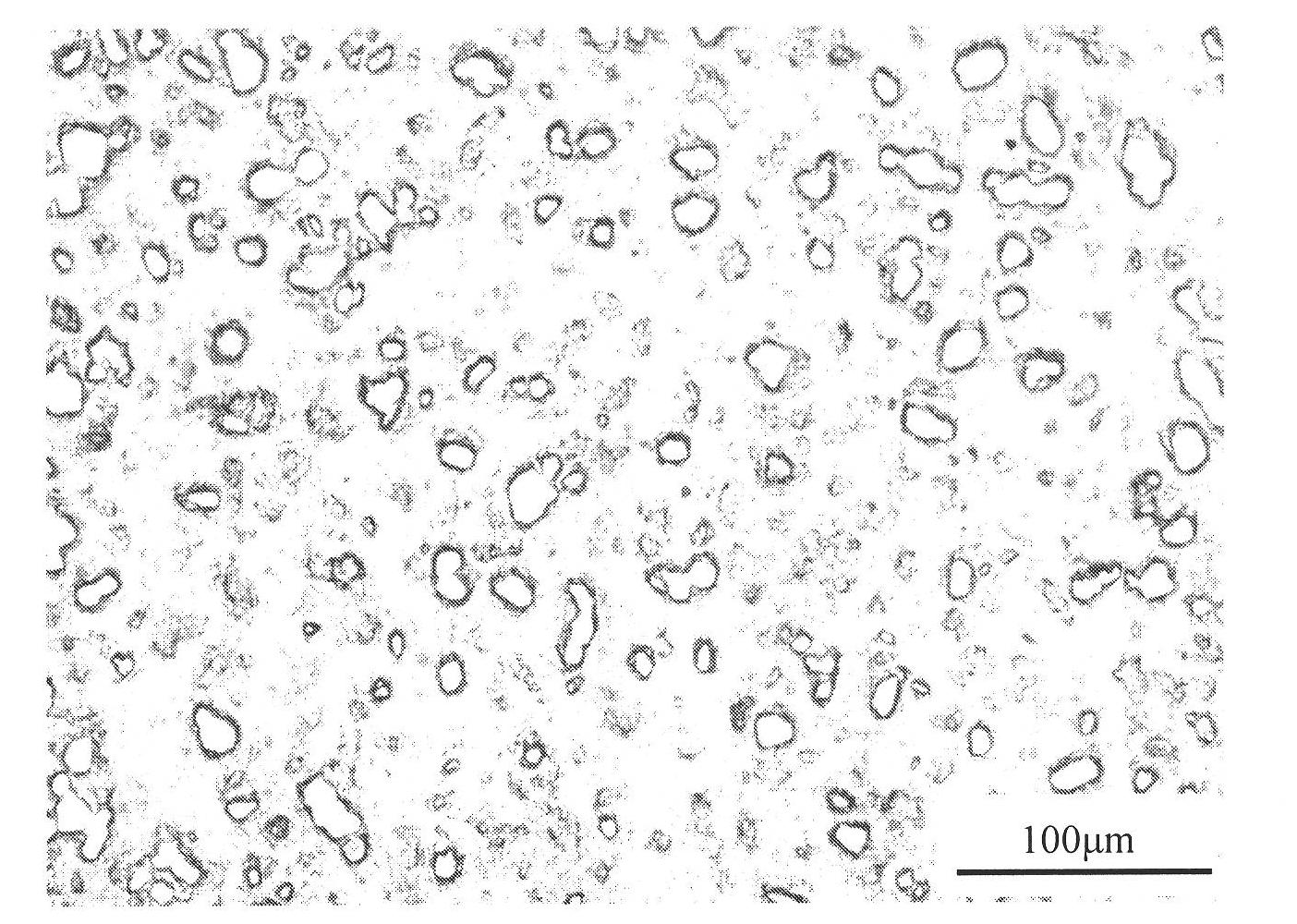

Embodiment 1

[0018] Industrial pure KBF 4 , industrial pure K 2 TiF 6 , pure aluminum powder and pure titanium powder are mixed evenly, and cold pressed by a hydraulic press to form a prefabricated block with a density of 50% to 60%. The weight percent of each component is: 30% KBF 4 , 43% K 2 TiF 6 , 18% pure aluminum powder, 9% pure titanium powder. Dry the prefabricated block at 100°C for 2 hours in a blast drying oven, press it into an aluminum melt at 800°C with a bell jar, the weight ratio of the prefabricated block is 31%, let it stand for 30 minutes, and then stir for 10 minutes , and then remove the slag and cast it into shape. The microstructure of the prepared Al5Ti1B master alloy is as follows figure 1 shown. It can be seen that except for the Al matrix, all of the master alloy structure is agglomerated Al 3 Ti phase and spherical TiB 2 Mutually. Agglomerated phase Al in tissue 3 The Ti size is between 10 μm and 30 μm, and the distribution is relatively uniform. Ti...

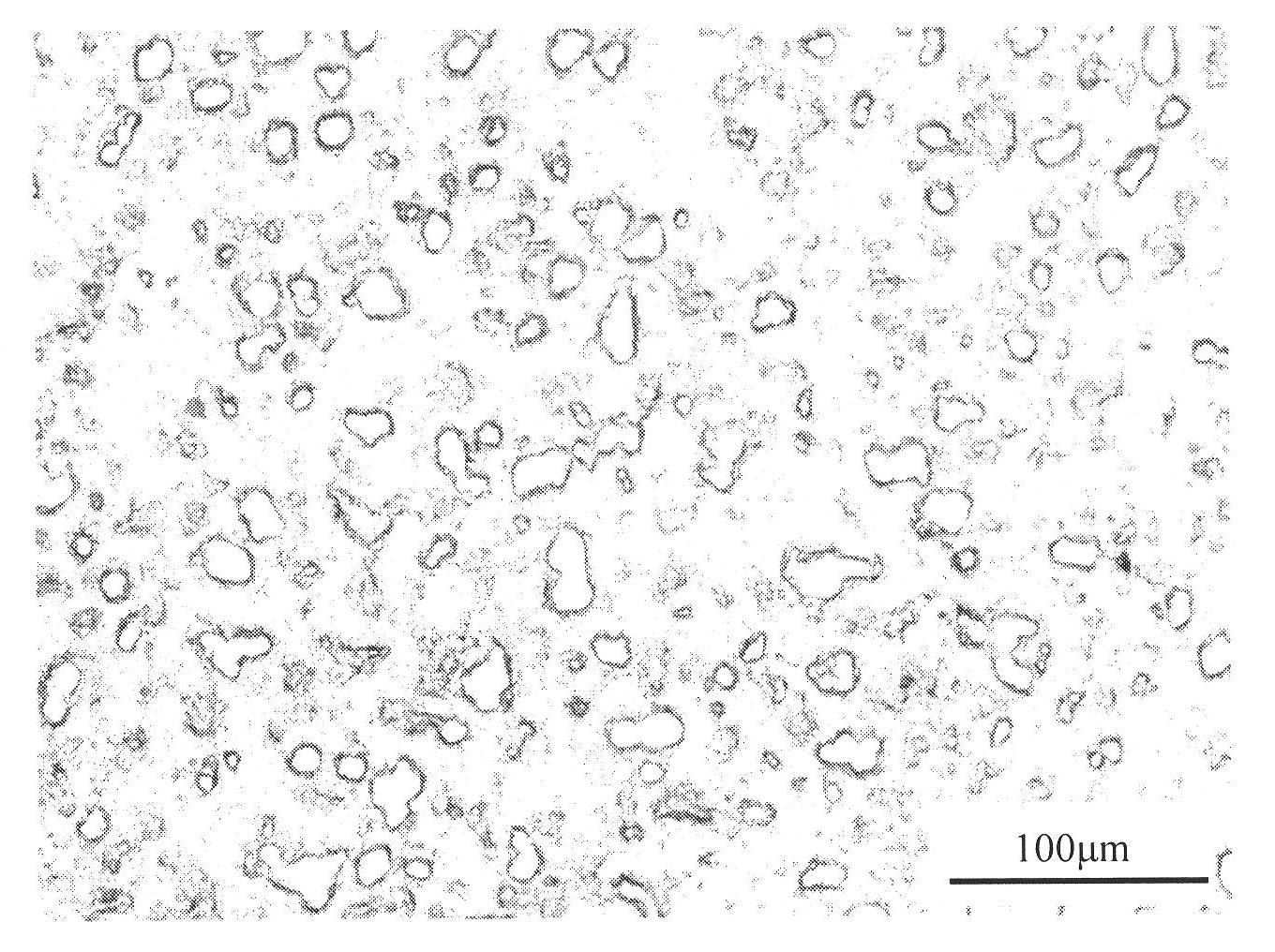

Embodiment 2

[0020] Industrial pure KBF 4 , industrial pure K 2 TiF 6 , pure aluminum powder and pure titanium powder are mixed evenly, and cold pressed by a hydraulic press to form a prefabricated block with a density of 50% to 60%. The weight percentage of each component is: 28% KBF 4 , 38% K 2 TiF 6 , 26% pure aluminum powder, 8% pure titanium powder. Dry the prefabricated block at 100°C for 2 hours in a blast drying oven, press it into an aluminum melt at 800°C with a bell jar, the weight ratio of the prefabricated block is 38%, let it stand for reaction for 30 minutes, and stir for 10 Minutes, then remove the slag and cast into shape. The microstructure of the prepared Al5Ti1B master alloy is as follows figure 2 shown. It can be seen that except for the Al matrix, all of the intermediate alloy structures are agglomerated Al 3 Ti phase and granular TiB 2 Mutually. The vast majority of regular agglomerated Al 3 The size of Ti phase is 20μm~35μm, and it is more evenly distri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com