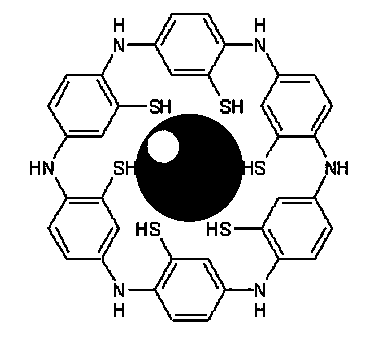

Poly-o-aminobenzenethiol nanometer metal composite particle and preparation method

A technology of o-aminothiophenol and nano-metal, which is applied in the direction of coating to achieve the effect of preventing agglomeration, high reproducibility and preventing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The steps of the preparation method of poly-o-aminothiophenol-nano metal composite particles are as follows:

[0032] 1) In an ice bath environment, dissolve 0.002-0.006 mol metal nitrate in 20-80mL dispersing-stabilizer solution with a concentration of 2%-8% by mass, and use mechanical stirring to make the above mixed solution foam. The amount is 5 times the volume of the dispersant-stabilizer solution, take 0.001-0.005 mol reducing agent and dissolve it in ice water, after the dissolution is complete, drop the reducing agent solution into the metal nitrate-dispersant solution drop by drop, so that the Metal ions are completely transformed into metal elements;

[0033] 2) After the above reaction is complete, add the reaction solution in step 1 into a centrifuge tube, and perform centrifugation at 2000 r / min for 2-4 min. Dilute the colloidal metal obtained by 100 times and conduct ultraviolet analysis to verify the concentration of nano-metal particles. synthesis;

...

Embodiment 1

[0040] 1) Dissolve 0.002mol copper nitrate in 20mL 8% polyvinyl alcohol solution in an ice bath environment. Use mechanical stirring to make the above mixed solution foam. The foaming amount is 5 times the volume of the dispersion-stabilizer solution. Take 0.001mol sodium borohydride and dissolve it in ice water. After the dissolution is complete, add the sodium borohydride solution drop by drop to copper nitrate -in the polyvinyl alcohol solution, the copper ions in the reaction solution are completely converted into copper simple substance;

[0041] 2) After the above reaction is complete, add the reaction solution in step 1) to the centrifuge tube, and perform centrifugation at 2000 r / min for 2 min, dilute the obtained colloidal metal by 100 times, and conduct ultraviolet analysis to verify the synthesis of nano-copper particles ;

[0042] 3) Take 0.0005 mol o-aminothiophenol and add it to 1mol / L hydrochloric acid solution, sonicate it to dissolve it completely, take an eq...

Embodiment 2

[0046] 1) Dissolve 0.004 mol silver nitrate in 40mL 4% polyethylene glycol solution in an ice bath environment. Use mechanical stirring to make the above mixed solution foam, and the foaming amount is 5 times of the volume of the dispersion-stabilizer solution. Take 0.001 mol of sodium borohydride and dissolve it in ice water. After the dissolution is complete, add the sodium borohydride solution drop by drop into the silver nitrate-polyethylene glycol solution, so that the silver ions in the reaction solution are completely converted into simple silver.

[0047] 2) After the above reaction is complete, add the reaction solution in step 1) to the centrifuge tube, and perform centrifugation at 2000 r / min for 3 minutes, dilute the obtained colloidal metal 100 times, and then conduct ultraviolet analysis to verify the concentration of silver nanoparticles. synthesis.

[0048] 3) Take 0.001mol o-aminothiophenol and add it to 1mol / L hydrochloric acid solution, sonicate it to disso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com