Method for preparing cathode material of lithium-sulfur battery

A cathode material, a technology for lithium-sulfur batteries, applied in the field of electrodes, can solve the problems of low active material load and utilization rate, poor electrochemical performance of lithium-sulfur batteries, and low sulfur load content, etc., to achieve excellent electrochemical performance, improve Cyclic performance, the effect of improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The first step, the preparation of graphene oxide:

[0030] Graphene oxide was prepared by the Hummers method;

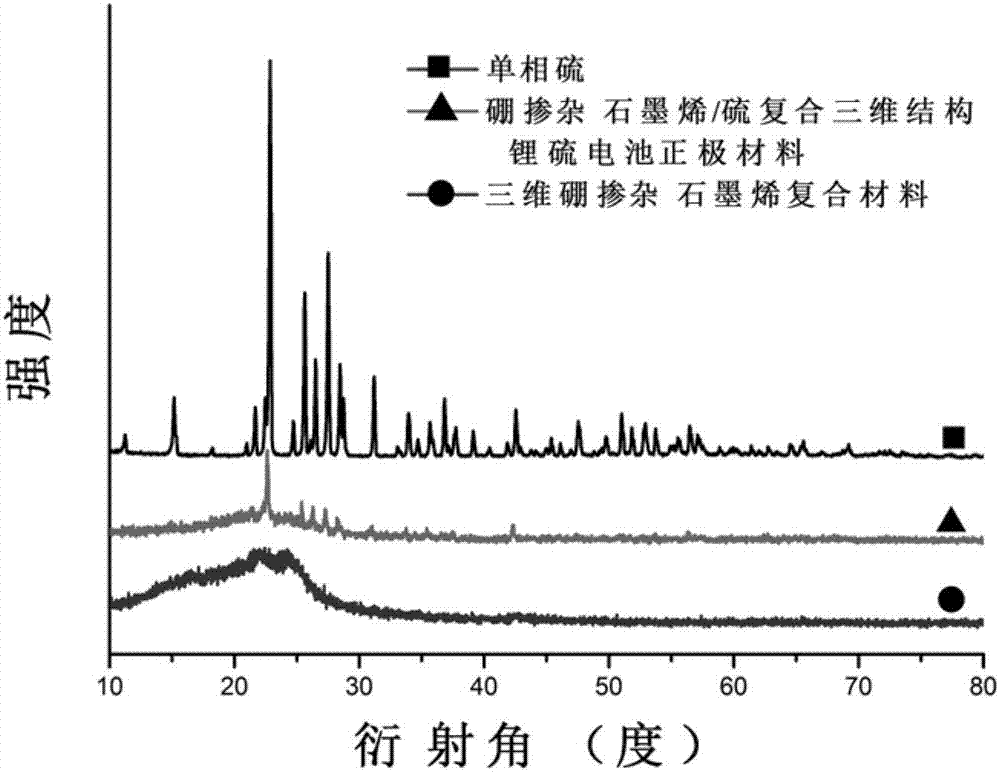

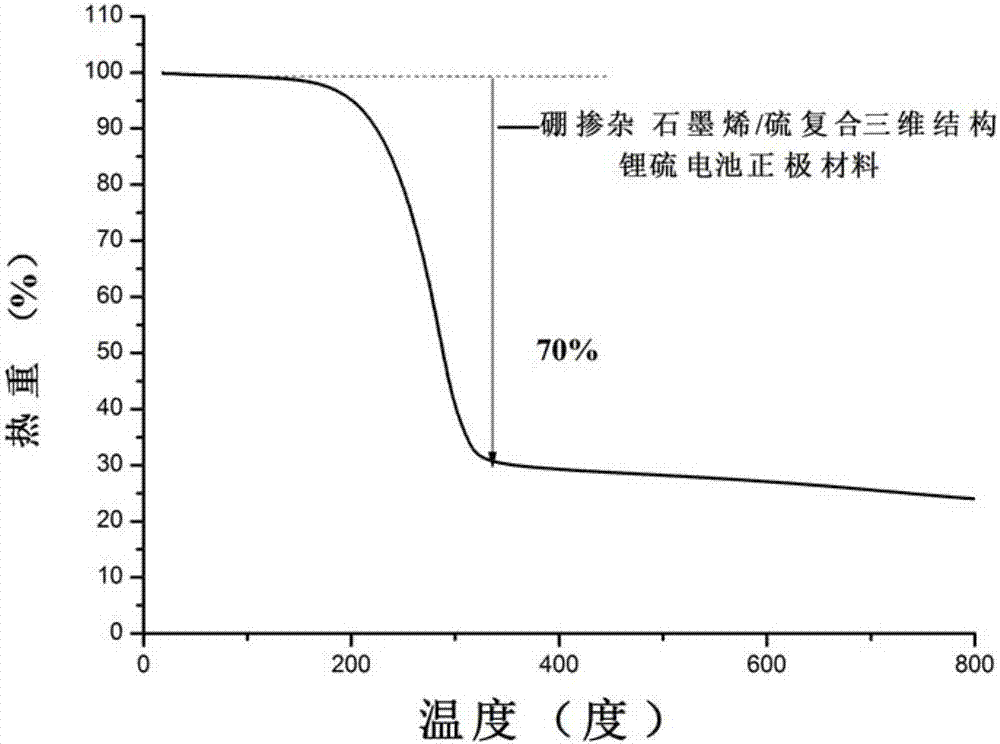

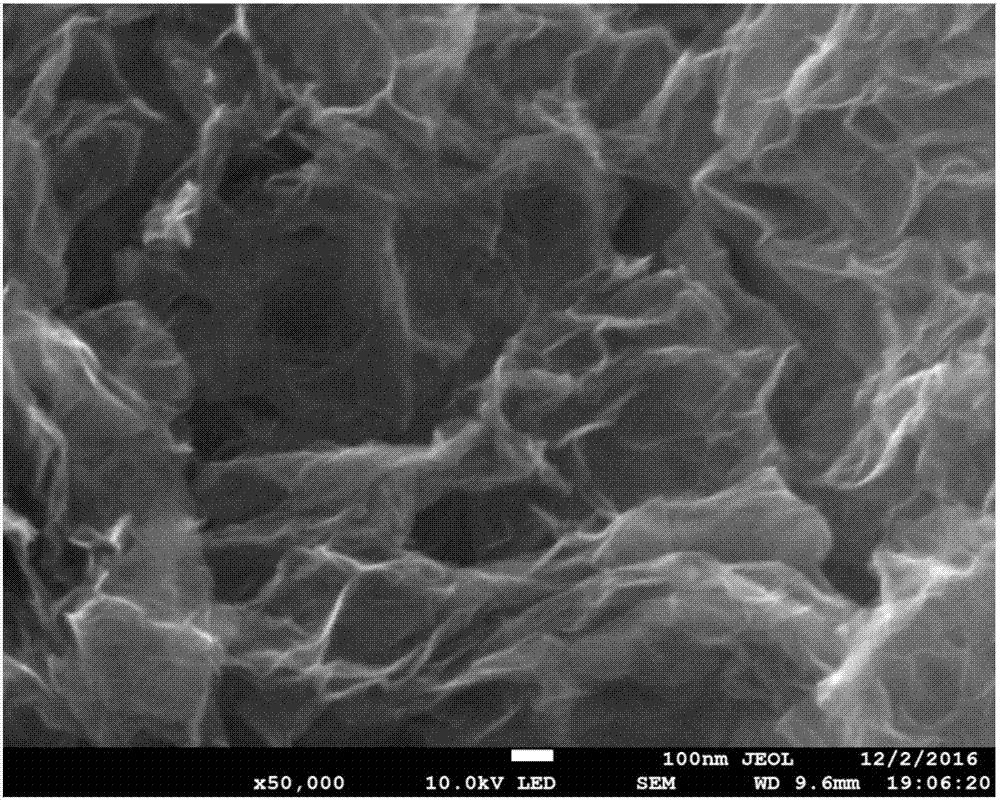

[0031] The second step is the preparation of boron-doped graphene / sulfur composite three-dimensional structure lithium-sulfur battery cathode material:

[0032] The graphene oxide, nano-sulfur powder and boric acid prepared in the first step will be weighed according to the mass ratio of 1:1:1 and placed in a ball mill jar, using a planetary ball mill, according to the ball-to-material ratio of 2:1, at 200 Ball mill for 6 hours at a speed of rpm to obtain a homogeneous mixture of the above three substances. According to the ratio of the mass ratio of the mixture to deionized water of 0.001:1, the mixture is added to deionized water, and ultrasonic dispersion is used at room temperature Ultrasonic disperse the mixture of graphene oxide, sulfur powder, boric acid and deionized water at 35kHz for 1 hour to obtain a suspension uniformly mixed with graphene oxide...

Embodiment 2

[0038] The first step, the preparation of graphene oxide:

[0039] Graphene oxide was prepared by the Hummers method;

[0040] The second step is the preparation of boron-doped graphene / sulfur composite three-dimensional structure lithium-sulfur battery cathode material:

[0041] The graphene oxide, nano-sulfur powder and boric acid prepared in the first step will be weighed according to the mass ratio of 1:5:2 and placed in a ball mill jar, using a planetary ball mill, according to the ball-to-material ratio of 3:1, at 400 Ball mill for 7 hours at a speed of rpm to obtain a homogeneous mixture of the above three substances. According to the mass ratio of the mixture to deionized water of 0.01:1, the mixture is added to deionized water, and ultrasonic dispersion is used at room temperature Ultrasonic disperse the above mixture of graphene oxide, sulfur powder, boric acid and deionized water at 50kHz for 2 hours to obtain a suspension uniformly mixed with graphene oxide, sulfu...

Embodiment 3

[0043] The first step, the preparation of graphene oxide:

[0044] Graphene oxide was prepared by the Hummers method;

[0045] The second step is the preparation of boron-doped graphene / sulfur composite three-dimensional structure lithium-sulfur battery cathode material:

[0046] The graphene oxide, nano-sulfur powder and boric acid prepared in the first step will be weighed according to the mass ratio of 1:10:3 and placed in a ball mill jar, using a planetary ball mill, according to the ball-to-material ratio of 4:1, at 600 Ball mill for 8 hours at a speed of rpm to obtain a homogeneous mixture of the above three substances. According to the ratio of the mass ratio of the mixture to deionized water of 0.03:1, the mixture is added to deionized water, and ultrasonic dispersion is used at room temperature Ultrasonic disperse the mixture of graphene oxide, sulfur powder, boric acid and deionized water at 60kHz for 3 hours to obtain a suspension uniformly mixed with graphene oxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| First discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com