Preparation method of boron-doping carbon nitride as well as product and application thereof

A carbon nitride and boron doping technology, applied in chemical instruments and methods, catalyst activation/preparation, chemical/physical processes, etc., can solve problems such as uneven doping of elements, and achieve uniform doping of elements and thin layers , Prepare the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

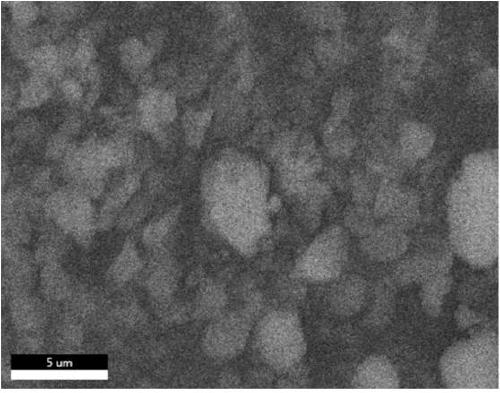

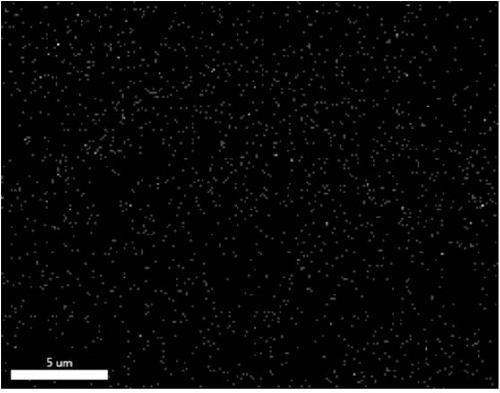

[0020] A preparation method of boron-doped carbon nitride, which involves hydrothermal reaction of melamine and boric acid, and then roasts the precursor synthesized by the reaction to prepare boron-doped carbon nitride with uniform doping and thinner lamellar structure. Carbon, comprising the steps of:

[0021] Accurately weigh melamine, boric acid and water. The mass ratio of melamine to boric acid is 1:0.1, and the mass ratio of melamine to water is 1:50. First, add melamine and boric acid to the hydrothermal reaction kettle, stir well and then put them in the oven After heating up to a certain temperature (120°C), react for a period of time (6 hours), then filter, wash and dry the product in vacuum to obtain the precursor;

[0022] The precursor was ground and pulverized and put into a crucible for calcination. The heating rate was 2.5°C / min, the final calcination temperature was 500°C, and the calcination time was 3 hours. The obtained powder was boron-doped carbon nitrid...

Embodiment 2

[0024] A kind of boron-doped carbon nitride, the steps are close to Example 1, prepared according to the following steps:

[0025] Accurately weigh melamine, boric acid and water (the mass ratio of melamine to boric acid is 1:0.3, and the mass ratio of melamine to water is 1:80). In the oven, heat up to a certain temperature (180°C) and react for a period of time (5 hours), then filter, wash, and vacuum dry the product to obtain the precursor;

[0026] After the precursor is ground and pulverized, it is placed in a crucible for calcination (where the heating rate is 2.5°C / min, the final calcination temperature is 550°C, and the calcination time is 4 hours), and the obtained powder is boron-doped carbon nitride.

Embodiment 3

[0028] A kind of boron-doped carbon nitride, the steps are close to Example 1, prepared as follows:

[0029] Accurately weigh melamine, boric acid and water (the mass ratio of melamine to boric acid is 1:0.05, and the mass ratio of melamine to water is 1:80). In the oven, heat up to a certain temperature (120°C) and react for a period of time (5 hours), then filter, wash and dry the product in vacuum to obtain the precursor;

[0030] After the precursor is ground and pulverized, it is placed in a crucible for calcination (the heating rate is 2.5°C / min, the final calcination temperature is 600°C, and the calcination time is 2 hours), and the obtained powder is boron-doped carbon nitride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com