Preparation method of local boron back surface passive field solar cell

A solar cell and back passivation technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of increasing the recombination rate of the back side, affecting the photoelectric conversion efficiency of the battery, etc., to improve the photoelectric conversion efficiency, increase the current opening voltage and filling. factor, the effect of increasing the open circuit voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

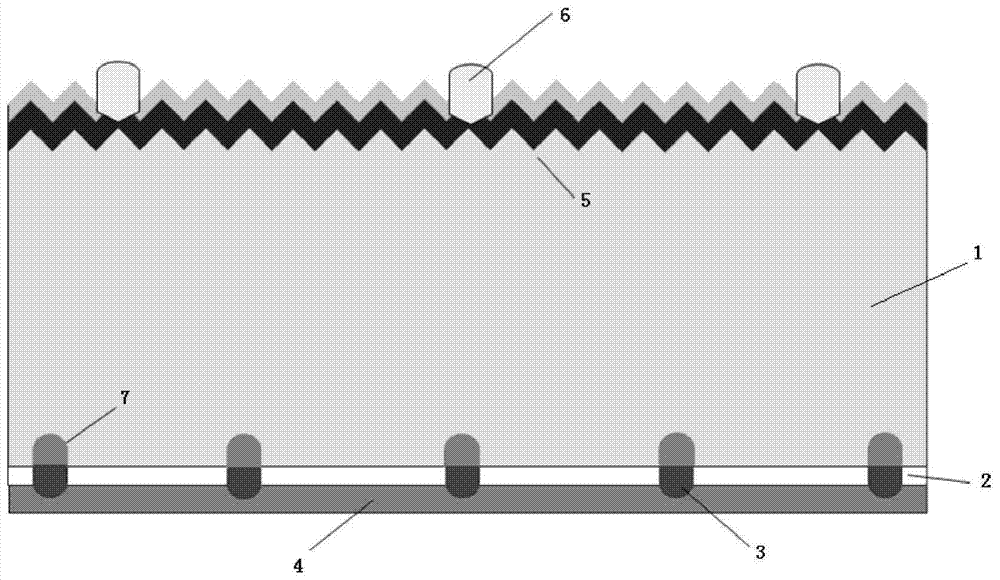

[0045] This embodiment illustrates a method for preparing a partially boron-back field-passivated solar cell. The specific steps of the preparation method are as follows:

[0046] A. Select a p-type monocrystalline silicon wafer 1 with a resistivity of 0.1-10Ω·cm, place it in a texturing tank, and place it in a deionized aqueous solution of sodium hydroxide with a mass percentage of 0.5-5%. Under the condition of 75~90℃, the surface texture is formed to form a suede structure;

[0047] B. Clean the surface of the silicon wafer with a chemical solution. The chemical solution is one or more mixed aqueous solutions of hydrofluoric acid, nitric acid, hydrochloric acid, sulfuric acid and other additives. The cleaning time is 0.5 to 60 minutes and the temperature is 5. ~90°C;

[0048] C. After cleaning the above velvet sheet, place it in a furnace tube at 700-1000° C. to carry out phosphorus (P) diffusion to prepare n-type emitter 5. The diffusion time is 70-150 minutes; the square...

Embodiment 2

[0065] This embodiment illustrates a method for preparing a partially boron-back field-passivated solar cell. The specific steps of the preparation method are as follows:

[0066] A. Select a lightly doped p-type single crystal silicon wafer with a resistivity of 0.1-10Ω·cm, place it in a texturing tank, and put it in a deionized aqueous solution of sodium hydroxide with a mass percentage of 0.5-5%. , at a temperature of 75-90°C, the surface is textured to form a suede structure;

[0067] B. Clean the surface of the silicon wafer with a chemical solution. The chemical solution is one or more mixed aqueous solutions of hydrofluoric acid, nitric acid, hydrochloric acid, sulfuric acid and other additives. The cleaning time is 0.5 to 60 minutes and the temperature is 5. ~90°C;

[0068] C. After cleaning the above textured sheet, place it in a furnace tube at 700-1000°C for phosphorus (P) diffusion to prepare an n-type emitter. The diffusion time is 70-150 minutes, and the square ...

Embodiment 3

[0085] This embodiment illustrates a method for preparing a partially boron-back field-passivated solar cell. The specific steps of the preparation method are as follows:

[0086] (1) Select a p-type single crystal silicon wafer, and cover the passivation layer on the back after pretreatment, such as figure 2 As shown in , where the passivation layer is one or both of aluminum oxide and silicon nitride, the pre-treatment includes texturing, cleaning, phosphorus diffusion, removal of back junction and removal of phosphosilicate glass, and the passivation layer is covered on the back Finally, it also includes the process of setting a passivation and anti-reflection layer on the front side of the silicon wafer;

[0087] (2) The boron source is completely covered on the passivation layer, such as image 3 As shown in , the boron source is a boron-containing slurry. The boron slurry generally contains boron-containing compounds such as boron oxide or other boron-doped media such ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com