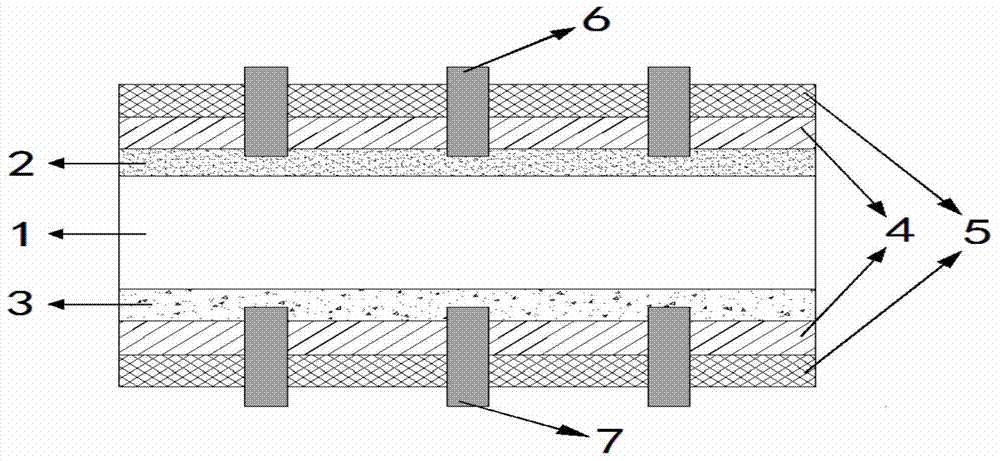

High efficiency N-type double-faced solar cell and preparation method thereof

A double-sided solar cell, N-type technology, which is applied in the field of solar cells to achieve the effects of high efficiency, easy operation, and increased open circuit voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The preparation method of the above-mentioned N-type double-sided solar cell comprises the following steps:

[0045] (1) Select an N-type single crystal raw silicon wafer with a resistivity of 1-12Ω·cm, dilute it with a mixture of hydrogen peroxide and ammonia water, and then treat it at 60-80°C for 3-10min to remove the mechanical properties on the surface of the silicon wafer. damage layer. After the above-mentioned treatment, the silicon wafer is corroded with potassium hydroxide solution and texturing buffer with a concentration of 1.6-2.0% and a temperature of 70-90 ° C. The time is controlled at 20-30 minutes, and then washed with diluent hydrofluoric acid. Finally, a pyramid-shaped suede structure is obtained.

[0046] (2) On the front side of the double-sided textured silicon wafer, an n+ diffusion layer is formed by doping, and the diffusion method is boron tribromide (BBr 3 ) source tube diffusion, or ion implantation method, or spray boron source on-line di...

Embodiment 2

[0056] The preparation method of the above-mentioned N-type double-sided solar cell comprises the following steps:

[0057] (1) Select an N-type single crystal raw silicon wafer with a resistivity of 1-12Ω·cm, dilute it with a mixture of hydrogen peroxide and ammonia water, and then treat it at 60-80°C for 3-10min to remove the mechanical properties on the surface of the silicon wafer. damage layer. After the above-mentioned treatment, the silicon wafer is corroded with potassium hydroxide solution and texturing buffer with a concentration of 1.6-2.0% and a temperature of 70-90 ° C. The time is controlled at 20-30 minutes, and then washed with diluent hydrofluoric acid. Finally, a pyramid-shaped suede structure is obtained.

[0058] (2) On the front side of the double-sided textured silicon wafer, an n+ diffusion layer is formed by doping, and the diffusion method is boron tribromide (BBr 3 ) source tube diffusion, or ion implantation method, or spray boron source on-line di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com