Silicon-based near infrared photoelectric detector structure and manufacturing method thereof

A technology of near-infrared light and electrical detectors, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of weak near-infrared light response, reduce leakage and background noise signals, have low surface roughness, and be easy to operate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

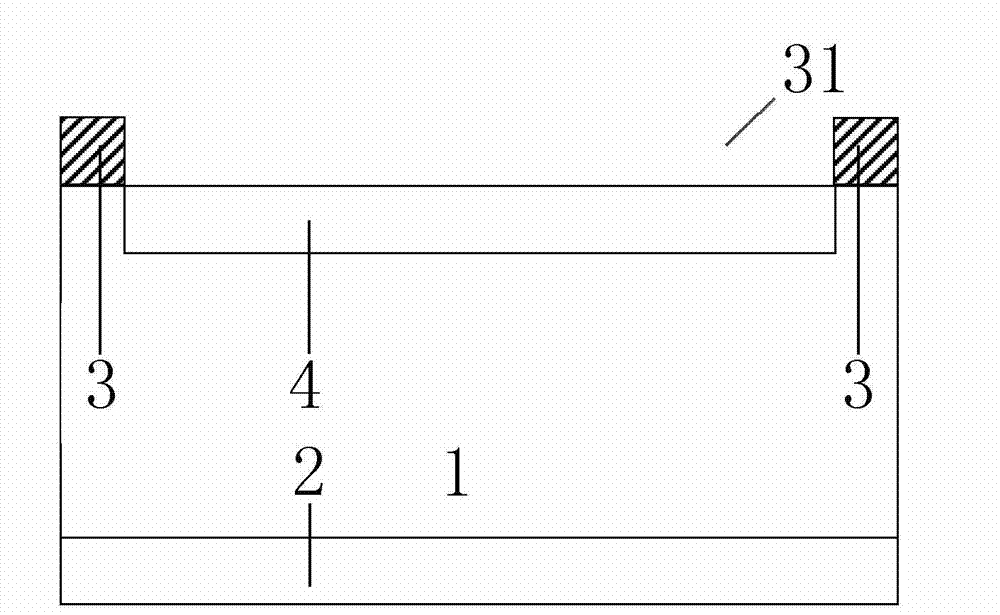

[0035] The silicon-based near-infrared photodetector structure provided by the present invention forms a pn junction at the interface between the p-type boron doped layer 4 and the n-type silicon substrate 1, and the pn junction region is activated by pulsed laser irradiation of chalcogenides The doping layer 5 enhances the absorption of near-infrared light by the silicon material, and the photogenerated electron-hole pairs are easily separated under the built-in electric field and reverse bias voltage and collected by the respective electrodes, and converted into photocurrent, which solves the traditional The problem of weak photoresponse of silicon photodetectors outside the wavelength of 1100nm has realized the near-infrared photodetection of silicon-based photodiodes.

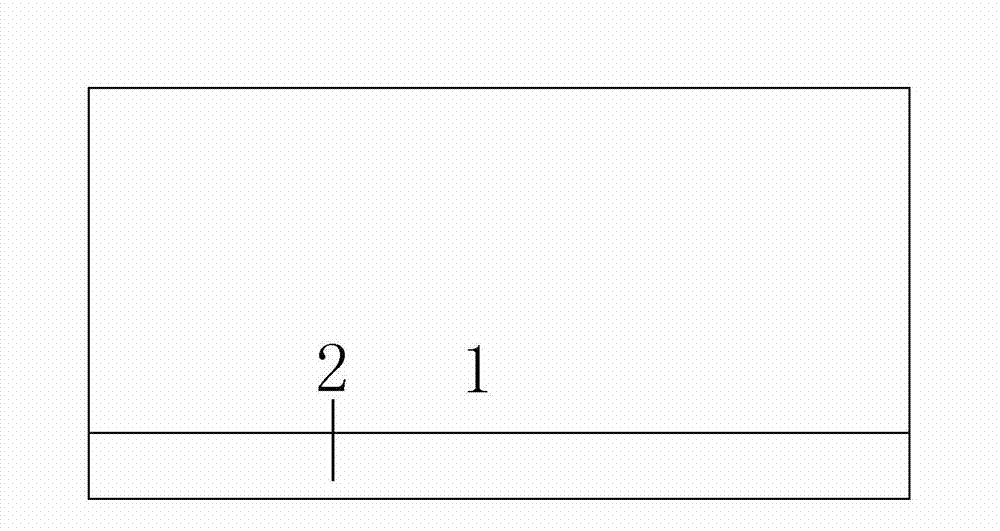

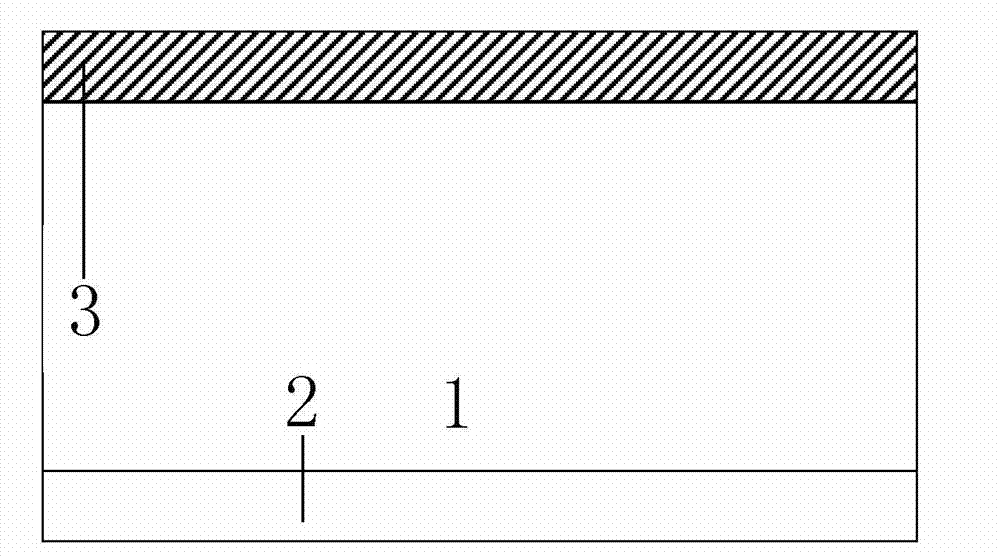

[0036] see Figure 6 As shown, the present invention provides a silicon-based near-infrared photodetector structure, comprising:

[0037] An n-type silicon substrate 1, the upper surface of the n-type sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com