Packaging material for photovoltaic module and preparation method of the packaging material

A technology for packaging materials and photovoltaic modules, applied in the fields of photovoltaic power generation, electrical components, powder coatings, etc., can solve the problems of heavy packaging materials, heavy weight, and high installation labor intensity, and achieve weight reduction, low manufacturing costs, and reduced installation. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

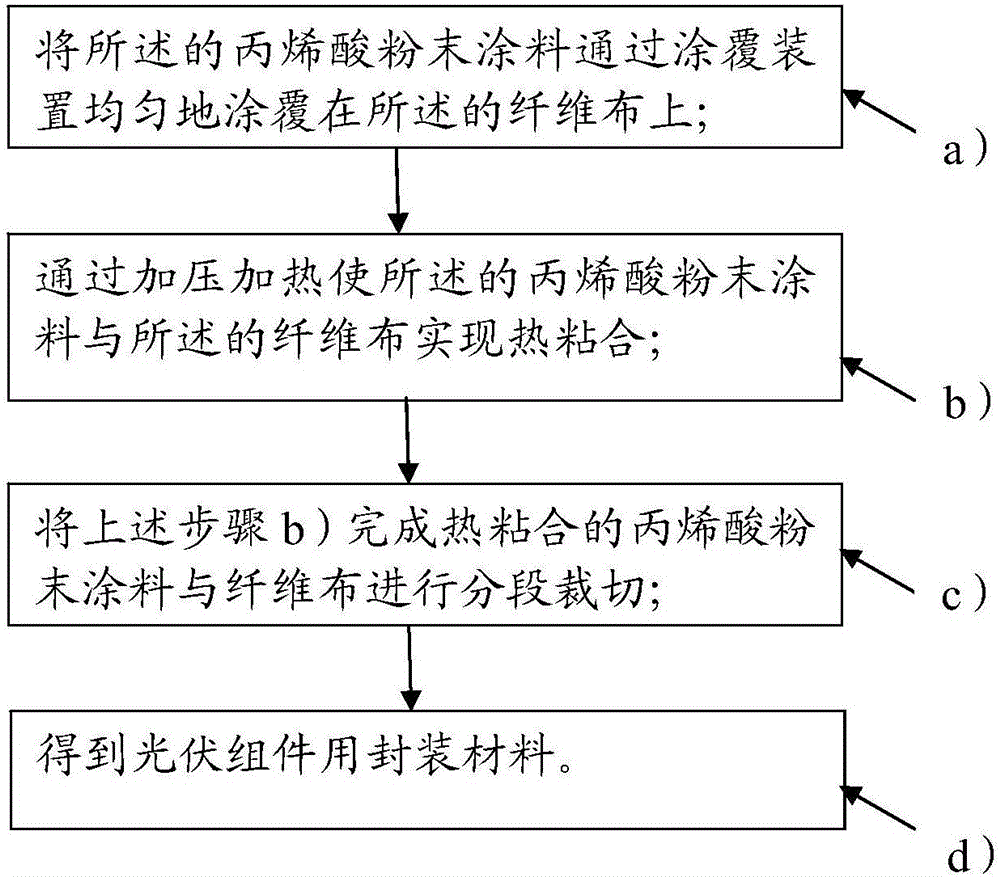

[0035]The embodiment of the present invention also discloses a preparation method of the above packaging material for photovoltaic modules, wherein the operation steps include the following:

[0036] a), the acrylic powder paint is evenly coated on the fiber cloth by the coating device;

[0037] b), the acrylic powder coating and the fiber cloth are thermally bonded by heating under pressure;

[0038] c), the acrylic powder coating and the fiber cloth that the above step b) has completed thermal bonding are cut in sections;

[0039] d), obtaining the encapsulation material for the photovoltaic module.

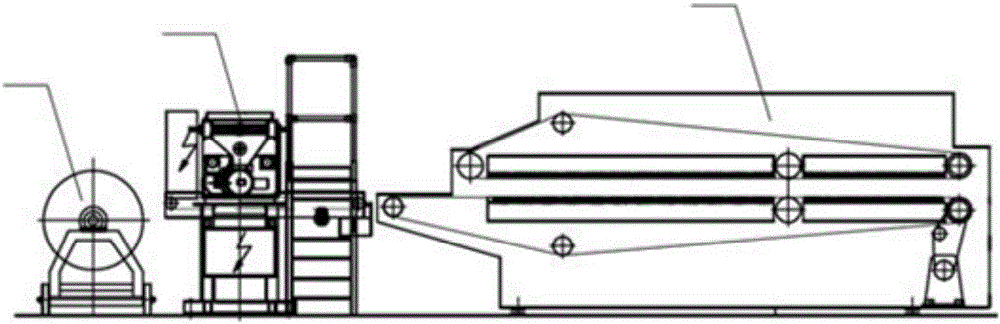

[0040] In the embodiment of the present invention, the acrylic powder coating is uniformly coated on the fiber cloth by the coating device, and then the acrylic powder coating is pre-bonded with the fiber cloth by pressing and heating, and finally cut into sections to obtain a photovoltaic material of a suitable size. The encapsulation material of the module can realize the a...

Embodiment 1

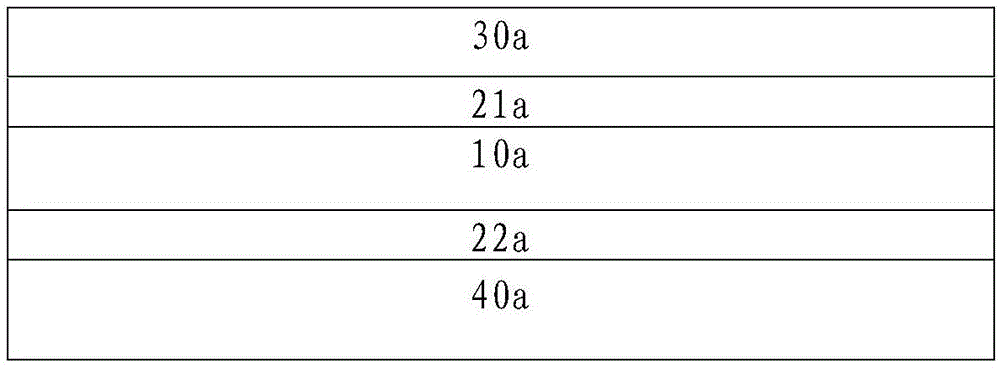

[0043] A packaging material for a photovoltaic module, the packaging material comprising the following raw materials in parts by weight:

[0044] 30-50 parts of fiber cloth, fiber cloth is made of fiber material weaving, preferably, in the embodiment of the present invention, fiber cloth is made of any one of plain weave, twill weave, satin weave, rib or mat weave by fiber material method or a combination of several weaving methods, specifically, in this embodiment, 30 parts of fiber cloth, fiber cloth is made of fiber material using plain weave, of course, those skilled in the art can according to actual needs Select other known weaving methods;

[0045] Preferably, in the embodiment of the present invention, the weight per unit area of the fiber cloth is in the range of 30-400 g / m 2 , while ensuring the strength of the fiber cloth, the lightweight of the fiber cloth is ensured. Specifically, in this embodiment, the weight per unit area of the fiber cloth is 100g / m 2 ; ...

Embodiment 2

[0063] In this embodiment 2, the encapsulation material comprises the following raw materials in parts by weight:

[0064] 35 parts of fiber cloth, which is made of fiber material by twill weaving;

[0065] The unit area weight of the fiber cloth is 30g / m2 ;

[0066] The fiber material is carbon fiber;

[0067] The monofilament diameter of the fiber material is 5 μm;

[0068] 65 parts of acrylic powder coatings, acrylic powder coatings include acrylic resins, curing agents and auxiliary agents;

[0069] The acrylic resin is a hydroxy acrylic resin;

[0070] The curing agent is phthalic anhydride, and the weight portion of phthalic anhydride accounts for 15% of the weight portion of the acrylic powder coating,

[0071] The auxiliary agent is polyamide wax, etc., and the weight portion of polyamide wax accounts for 10% of the weight portion of the acrylic powder coating;

[0072] The unit area weight of acrylic powder coating on fiber cloth is 150g / m 2 ;

[0073] In the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com