Silicon wafer cutting technology

A silicon wafer cutting and crafting technology, applied in the direction of work accessories, manufacturing tools, stone processing equipment, etc., can solve the problem that the mortar cannot meet the cutting process requirements, and achieve the effects of reducing cutting costs, significant economic benefits, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] 1. Recycling of silicon carbide and cutting fluid

[0058] Through solid-liquid separation, silicon carbide and cutting fluid are recovered, and the standards for recycling silicon carbide and cutting fluid are as follows:

[0059] Standards for the use of recycled silicon carbide:

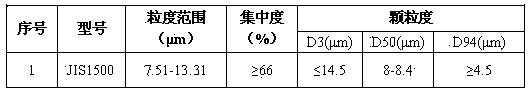

[0060] Graininess:

[0061]

[0062] Among them, D3 means that the proportion of silicon carbide particles with a diameter greater than 14.5 μm is 3%, D50 means that the average particle size of silicon carbide particles is between 8-8.4 μm, and D94 means that 94% of silicon carbide particles have a diameter greater than 4.5 μm.

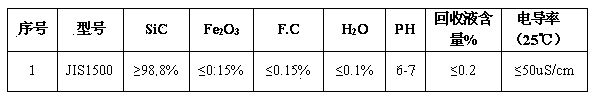

[0063] Requirements for recycling silicon carbide components:

[0064]

[0065] The performance of recycled cutting fluid is as follows:

[0066] Appearance (25°C): Colorless, odorless, transparent liquid;

[0067] chroma: 35;

[0068] Refractive index (20°C): 1.4600;

[0069] ph value (5% aqueous solution): 6.5;

[0070] Moisture ≤0.40%, measured b...

Embodiment 2

[0099] 1. Recycling of silicon carbide and cutting fluid

[0100] Through solid-liquid separation, silicon carbide and cutting fluid are recovered, and the standards for recycling silicon carbide and cutting fluid are as follows:

[0101] Standards for the use of recycled silicon carbide:

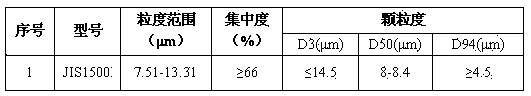

[0102] Graininess:

[0103]

[0104] Silicon carbide composition requirements:

[0105]

[0106] The performance of recycled cutting fluid is as follows:

[0107] Appearance (25°C): Colorless, odorless, transparent liquid;

[0108] chroma: 30;

[0109] Refractive index (20°C): 1.4620;

[0110] ph value (5% aqueous solution): 6.8;

[0111] Moisture %≤0.40, measured by moisture detector;

[0112] Rotational viscosity (25°C): 43.0mPa?s;

[0113] Density (20°C): 1.115g / cm3, measured by density meter;

[0114] Conductivity (25°C): 6.5 μS / cm.

[0115] 2. Mortar ratio

[0116] Preparation of cutting auxiliary material mortar: the mortar is composed of silicon carbide and cuttin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com