Preparation method of hydrophobic nano-silica

A nano-silicon dioxide and silicon dioxide technology, applied in the field of nano-materials, can solve the problems of insufficient yield of trichlorosilane, poor dispersion of silica, and high investment scale, and achieve good industrial application prospects and high hydrophobicity. performance, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

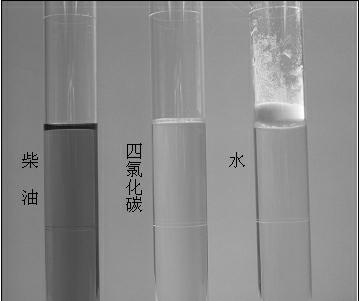

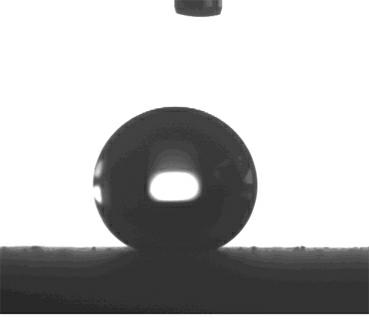

Image

Examples

Embodiment 1

[0028] Weigh 23g of sodium metasilicate in 140ml of deionized water and transfer to a 250ml three-neck flask. Under mechanical stirring at room temperature, gradually add silicon tetrachloride dropwise until the pH value of the solution is 8, control the dropping time for 8 minutes, and then react for 1 hour; then add modifier KH151 according to the molar ratio of modifier: silicon dioxide is 1:2 (Vinyltriethoxysilane), react at 60°C for 8h to obtain a silica emulsion. The resulting emulsion was washed with deionized water until by-products were removed. The resulting product was suction filtered and dried at 100°C to obtain hydrophobic nano-silica.

Embodiment 2

[0030] Weigh 23g of sodium metasilicate in 160ml of deionized water and transfer to a 250ml three-neck flask. Under mechanical stirring, gradually add silicon tetrachloride dropwise until the pH value of the solution is 4, control the dropping time to 15min, and the reaction temperature is 40°C, and then react for 2h after the dropping; (γ-(methacryloyloxy)propyltrimethoxysilane): dichlorodimethylsilane: silicon dioxide = 1:4:20, react at 50°C for 3 hours, and react at 80°C for 4 hours to obtain silica lotion. The resulting emulsion was washed with deionized water until by-products were removed. The resulting product was suction filtered and dried at 150°C to obtain hydrophobic nano-silica.

Embodiment 3

[0032] Weigh 31g of natron in 170ml of deionized water and transfer to a 250ml three-neck flask. Under mechanical stirring, silicon tetrachloride was gradually added dropwise until the pH value of the solution was 9, the reaction temperature was controlled at 50°C, the dropwise addition time was 5min, and after the dropwise addition was completed, reacted for 4h to obtain a silicon dioxide emulsion. The resulting emulsion was washed with tap water until by-products were removed. Disperse the washed filter cake in deionized water, add a mixed modifier, wherein, in molar ratio, isooctanoic acid: perfluorooctanoic acid: silicon dioxide = 1:6:15, and react at 70°C for 7 hours to obtain a silica emulsion. The product is filtered by suction and dried at 190°C to obtain hydrophobic nano-silica.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com