Solar cell with high conversion efficiency

A solar cell, high-conversion technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve problems such as process incompatibility, and achieve the effects of improving conversion efficiency, improving light absorption, and enhancing light absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

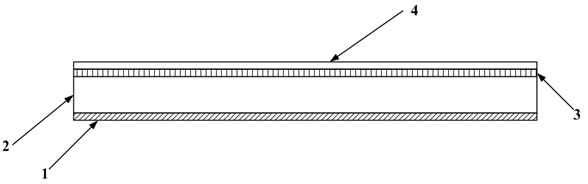

[0021] figure 1 Shown is a solar cell structure, the basic material of which is a P-type monocrystalline silicon wafer, the upper surface of which is an N+-type region to form a PN+ junction 2, and a grid-like metal electrode 3 is formed on the upper surface of the PN+ junction 2, and the grid-like metal electrode The surface of 3 is evenly covered with an anti-reflection film 4, and a metal bottom electrode 1 is formed on the lower surface of the P-type single crystal silicon wafer.

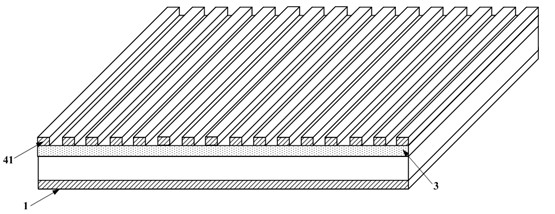

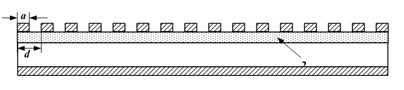

[0022] Such as figure 2 , Figure 2.a As shown, periodic nano-gratings 41 are formed in the anti-reflection coating 4, and the nano-gratings 41 are processed in the anti-reflection coating 4, and the porosity P= a / d (consistent with the duty cycle of the grating), by changing the period d and the duty cycle can change the porosity of the grating. According to formula (1), the equivalent refractive index of the anti-reflection coating is also changed, so that the equivalent refractive ind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| lattice constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com