Serially connected type perovskite/homojunction silicon laminated solar cell and preparation method thereof

A technology of solar cells and perovskite, applied in the field of solar cells, can solve the problem of high preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

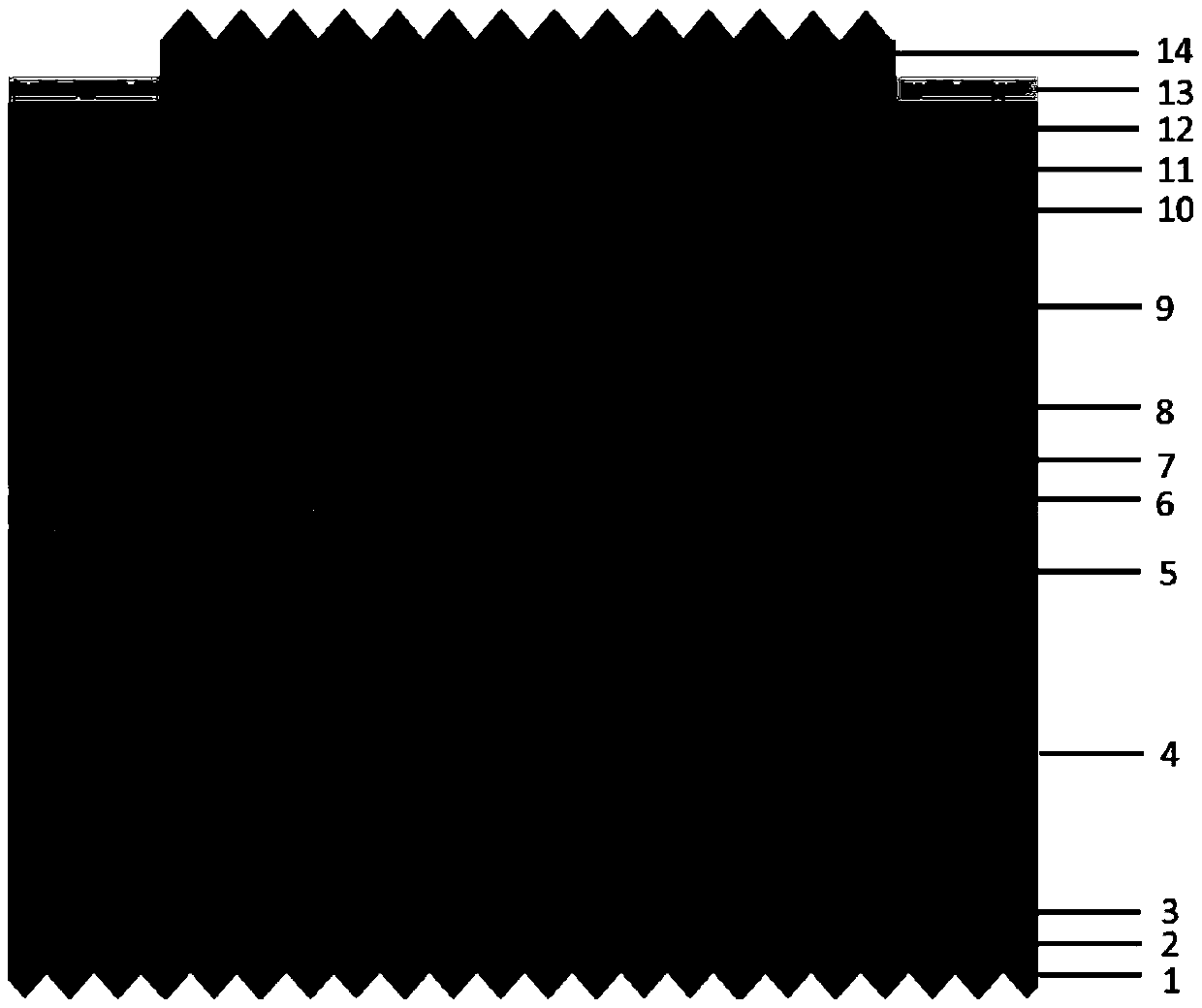

[0053] The invention provides a method for preparing a tandem perovskite / homojunction silicon laminated solar cell comprising the following steps:

[0054] Step 1: Texturing the surface of n-type silicon 4 with but not limited to alkaline solution.

[0055] Step 2: using but not limited to phosphorous compound to partially or fully diffuse phosphorous on the back of the silicon to form a heavily doped junction to form a partial or all n-type heavily doped layer 3 .

[0056] Step 3: Using but not limited to tubular boron diffusion or chain boron diffusion to expand boron on the front of the battery to form a p-type heavily doped emitter 5 .

[0057] Step 4: using but not limited to thermal growth, atomic deposition (ALD) or plasma enhanced chemical vapor deposition (PECVD) to prepare a bottom electrode passivation layer on the silicon backside.

[0058] Step 5: using but not limited to the method of opening holes by laser etching to make holes in the bottom electrode to prepar...

Embodiment 1

[0071] In this embodiment, silver electrode / n+ / SiO 2 / n-type silicon / p+ / SnO 2 / Perovskite light-absorbing layer / Spiro-OMeTAD / Ultra-thin Cu / Ag metal electrode structure to prepare tandem perovskite / homojunction silicon tandem solar cells.

[0072] The specific preparation process is as follows: adopt the n-type silicon wafer 4 with a resistivity of 5 ohm-cm prepared by the suspension zone melting method; use alkali to make texture on the back of the n-type silicon wafer; Type heavily doped layer 3; positive boron expansion to form pn homojunction to form p-type heavily doped emitter 5, junction depth 2μm; silicon cell surface prepared by thermal growth method SiO 2 After the ultra-thin passivation layer, local opening is performed to prepare the bottom electrode opening passivation layer 2; finally, a 1-micron silver electrode is evaporated to prepare the metal bottom electrode 1; the front surface of the silicon wafer is directly treated with ozone to obtain ultra-thin SiO 2...

Embodiment 2

[0074] In this embodiment, silver electrode / n+ / SiO 2 / n-type silicon / p+ / SiO 2 / SnO 2 / Perovskite Light Absorbing Layer / Spiro-OMeTAD / MoO x / ITO / Ag gate electrode / MgF 2 Structure preparation of tandem perovskite / homojunction silicon tandem solar cells.

[0075]The specific preparation process is as follows: adopt the n-type silicon wafer 4 with a resistivity of 5 ohm-cm prepared by the suspension zone melting method; use alkali to make texture on the back of the n-type silicon wafer; type heavily doped layer 3; the front side is expanded with boron to form a pn homojunction to form a p-type heavily doped emitter 5 with a junction depth of 3 μm; the silicon cell surface is prepared by thermal growth of SiO 2 After the ultra-thin passivation layer, local opening is performed to prepare the bottom electrode opening passivation layer 2; finally, a 1-micron silver electrode is evaporated to prepare the metal bottom electrode 1; the front surface of the silicon wafer is directly t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com