Method for producing small-sized tin indium oxide nano-wire material in low-temperature

An indium tin oxide nano- and small-scale technology is applied in chemical instruments and methods, polycrystalline material growth, metal material coating processes, etc. Good, low preparation temperature, the effect of reducing the substrate temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

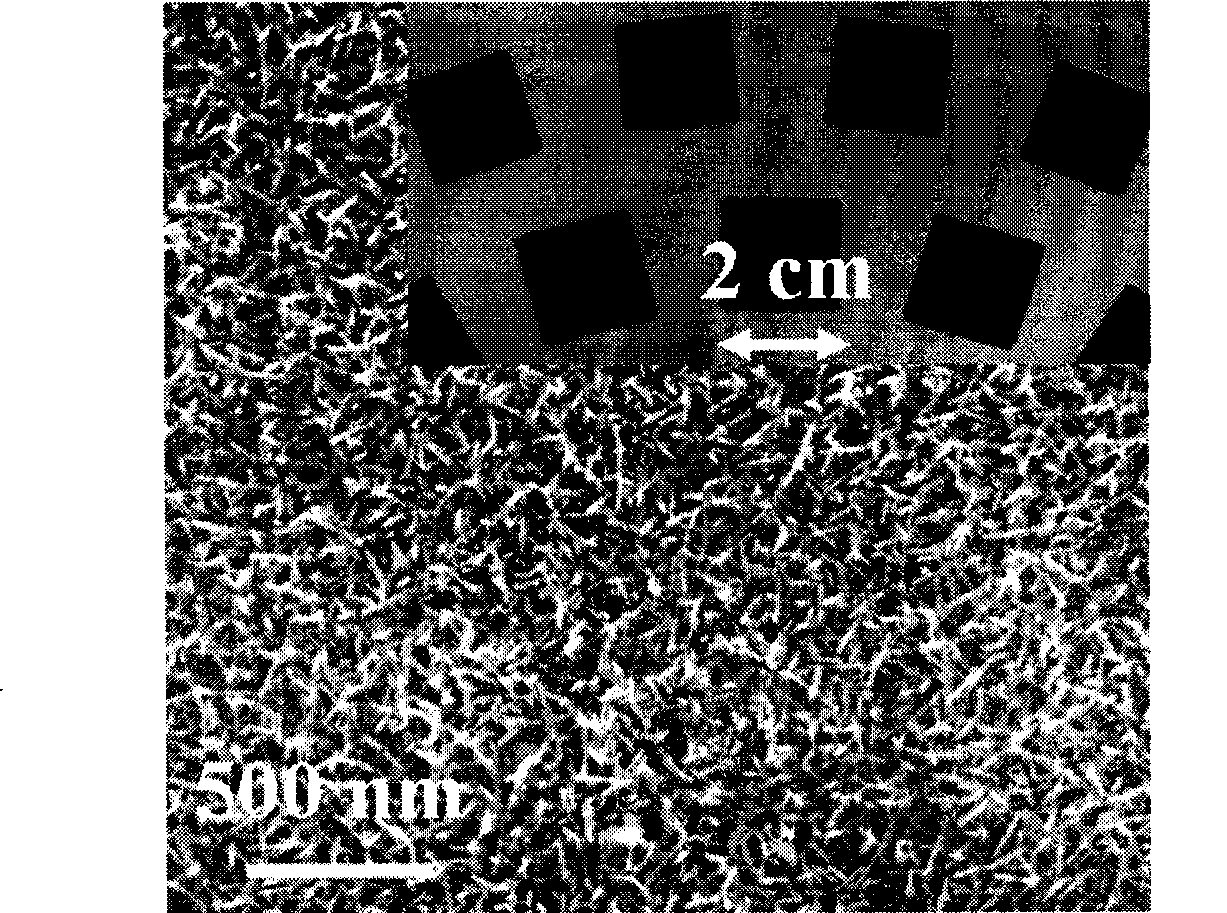

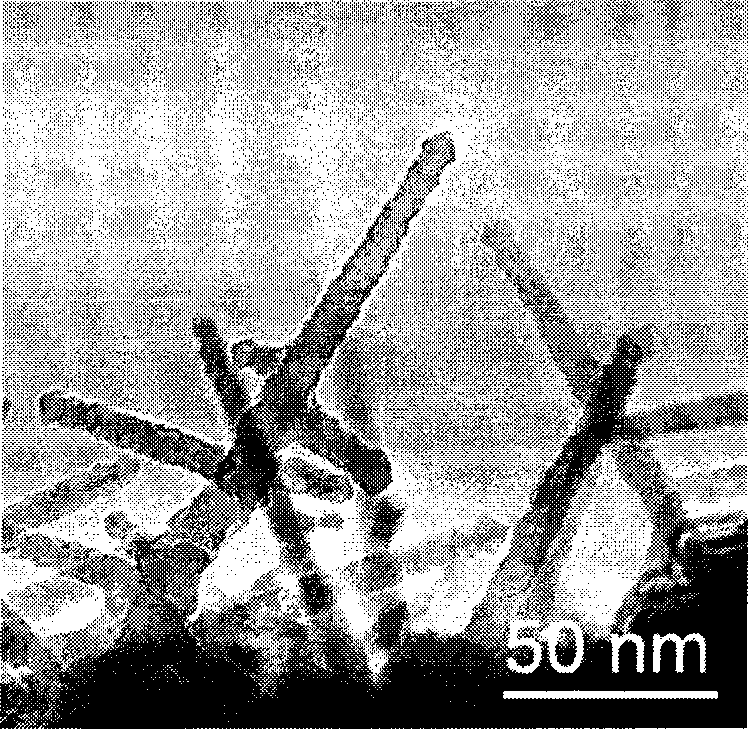

Examples

Embodiment 1

[0025] The preferred specific steps of the method for preparing small-sized indium tin oxide nanowire material at low temperature in this embodiment are:

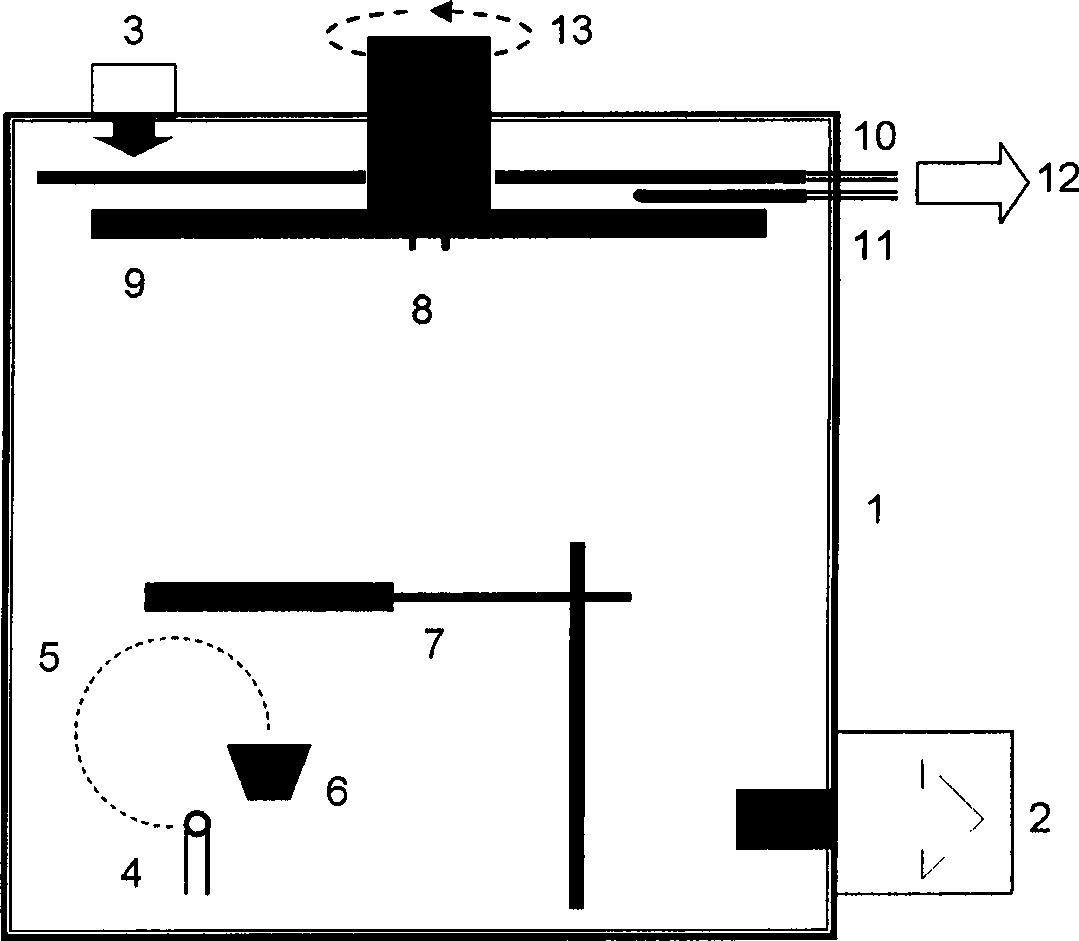

[0026] 1. In the electron beam evaporator (ZD450, Chengdu Nanguang Machinery, see figure 1 ) into the block or sheet ITO (In / Sn=85 / 15) target, put the cleaned single crystal silicon (or quartz, glass) substrate on the sample holder, the sample holder and the target The distance is 40cm, and there is a baffle in the middle.

[0027] 2. Close the door of the evaporation chamber of the electron beam evaporator, start vacuuming, and bake the chamber at ≥100 degrees Celsius (not higher than 300 degrees Celsius). After vacuuming for about 2-3 hours, the baking temperature of the cavity should reach above 150 degrees Celsius, and the vacuum in the cavity should be lower than 5×10 -4 Pa.

[0028] 3. After the substrate temperature reaches 150±10 degrees Celsius and the vacuum degree is relatively stable, start to evaporate. Adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com