Method for preparing black silicon based on liquid-phase chemical reaction

A liquid-phase chemical reaction, black silicon technology, applied in the fields of polysilicon and amorphous silicon surface texture, black silicon preparation, and monocrystalline silicon, can solve problems such as difficulty in obtaining large-scale promotion, high equipment investment, and limited application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

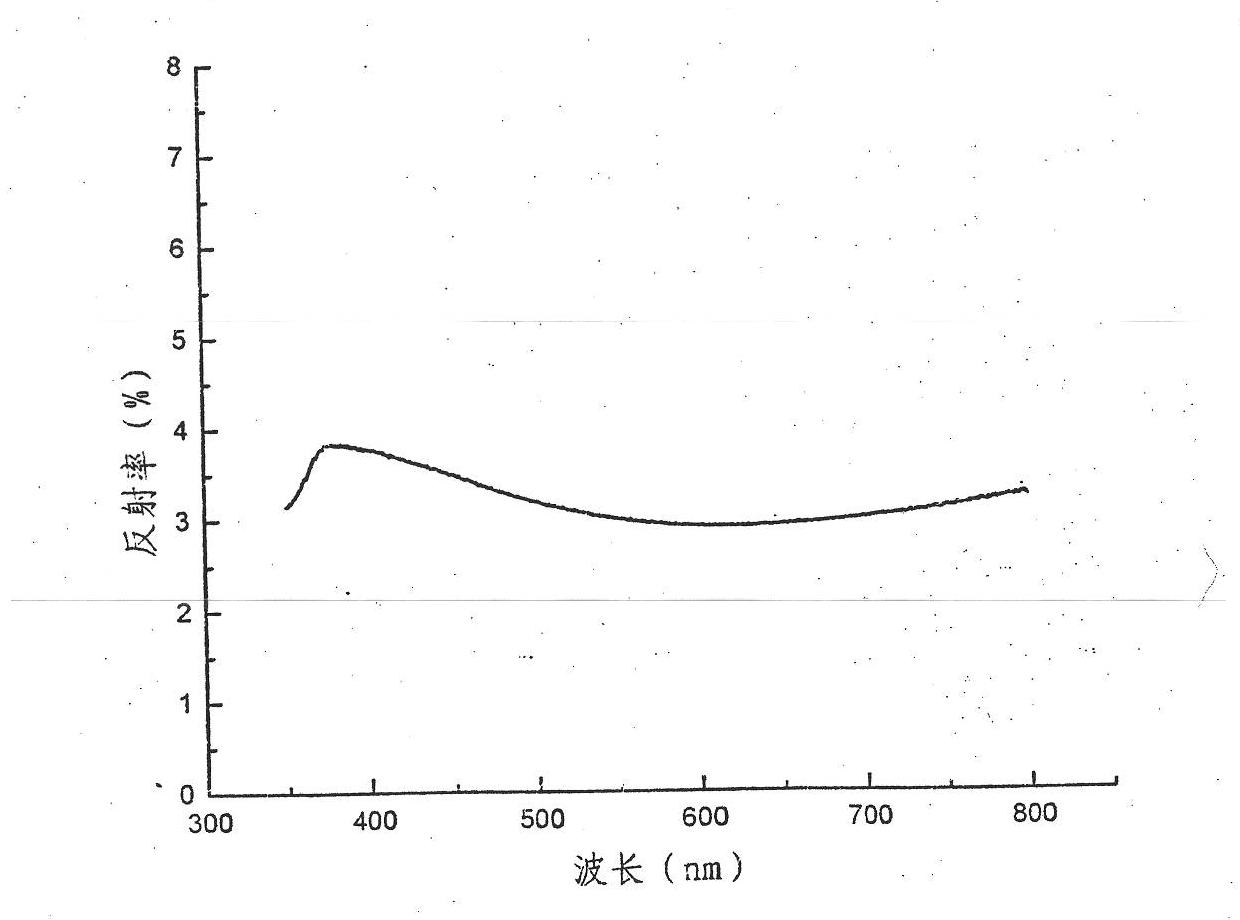

[0015] Embodiment 1: be 1: 4 configuration 100 milliliters mixed solutions by the weight ratio of hydrofluoric acid and hydrogen peroxide, wherein the weight percent concentration of hydrofluoric acid is 8%, and the weight percent concentration of hydrogen peroxide is 24%. Put the unpolished single crystal silicon chip into the solution heated to 15°C, then add 0.2 mmol of chloroauric acid, take out the silicon chip after 4.5 minutes, rinse it, and let it dry naturally. The prepared black silicon material absorbs more than 95% of the light in the wavelength range of 300-800nm. The SEM top view of black silicon material is as follows figure 1 as shown, figure 1 A structure of a large number of silicon micro-holes is formed on the surface of the black silicon material. figure 2 It shows that the light absorption of the black silicon material in the wavelength range of 300-800nm is as high as 95%.

Embodiment 2

[0016] Embodiment 2: be 1: 3 configuration 100 milliliters mixed solutions by the weight ratio of hydrofluoric acid and hydrogen peroxide, wherein the weight percent concentration of hydrofluoric acid is 5%, and the weight percent concentration of hydrogen peroxide is 10%. Heat the solution to 50°C, put the monocrystalline silicon wafer into the mixed solution heated to 25°C, then add 1 mmol of silver nitrate, take out the silicon wafer after 60 minutes, rinse it, and dry it naturally to prepare the black silicon material .

Embodiment 3

[0017] Embodiment 3: be 1: 6 configuration two parts of identical 100 milliliters mixed solutions by the weight ratio of hydrofluoric acid and hydrogen peroxide, wherein the weight percent concentration of hydrofluoric acid is 20%, the weight percent concentration of hydrogen peroxide 0.5%. Put the monocrystalline silicon chip into the first solution heated to 25°C, then add 1 mmol of silver nitrate, take out the silicon chip after 1 minute; heat the other solution to 50°C, put the silicon chip into Immediately, 2 mmol of ferric nitrate was added to the solution, and after 50 minutes, the silicon chip was taken out, rinsed, and dried naturally to prepare a black silicon material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com