Resin abrasive cutting wheel and manufacturing method thereof

A technology for cutting grinding wheels and resins, used in bonding grinding wheels, manufacturing tools, metal processing equipment, etc., can solve the problems of increasing costs, complex processes, increasing production costs, etc., and achieves high cutting efficiency, improved cutting performance, and is not easy to block. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

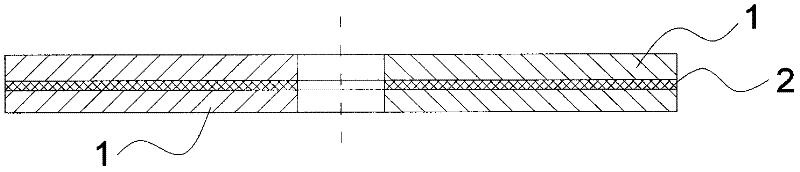

[0039] The resin cutting grinding wheel to be prepared in this embodiment is a flat grinding wheel, such as figure 1 shown.

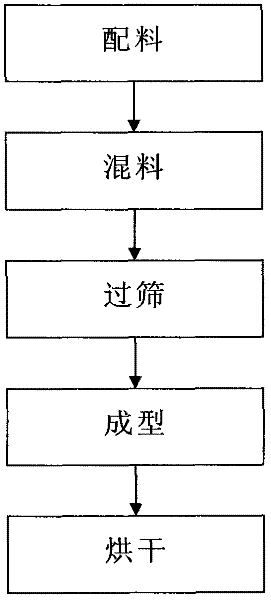

[0040] First, weigh raw materials with a certain mass ratio for batching. The types of raw materials and their weight percentage ratios are respectively 62-70% of brown corundum, 4-10% of black silicon carbide, 18-20% of phenolic resin, and the rest are fillers. Hemihydrate gypsum powder. Wherein, a part of the phenolic resin is liquid, and the rest is powder, and the mass ratio of the two is 1:2. Black silicon carbide is also in powder form, and brown corundum is between 24 and 36 mesh in size. Brown corundum with mixed grain size is used, so that the finer abrasive grains can be filled into the coarser abrasive grains, the gap between the abrasive grains is reduced, the specific surface area of the abrasive grains is increased, the resin bond bridge is short and thick, and the grinding wheel is effectively improved. strength and grinding efficien...

Embodiment 2

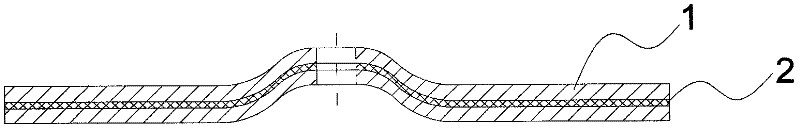

[0046] The resin cutting grinding wheel to be prepared in this embodiment is a cymbal type grinding wheel, such as figure 2 shown.

[0047] Similarly, batching is carried out first, and the types of raw materials and their weight percentages are respectively 65% of brown corundum, 5% of black silicon carbide, 19% of phenolic resin, 10% of hemihydrate gypsum powder, and 1% of carbon black. In the phenolic resin, the mass ratio of the liquid phenolic resin to the powdered phenolic resin is 1:4.

[0048] Then, carry out the same mixing and sieving steps as in the first embodiment.

[0049] The forming steps for cymbal wheels are slightly different from those for parallel wheels. Similarly, for example, if three grinding wheels are formed at one time, three parts of molding materials are weighed first, and each part is just or slightly more than the weight required to manufacture one resin cutting grinding wheel. Also put half of the molding material in the forming mold and sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com