Method for preparing black silicon by metallic copper ion auxiliary etching

An ion-assisted, metallic copper technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem of nanowire structure unfavorable photo-generated carrier collection, difficult to prepare good contact metal electrodes, and reduce photovoltaic device conversion efficiency, etc. problems, to achieve the effect of large-area production, easy cleaning, and improved conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

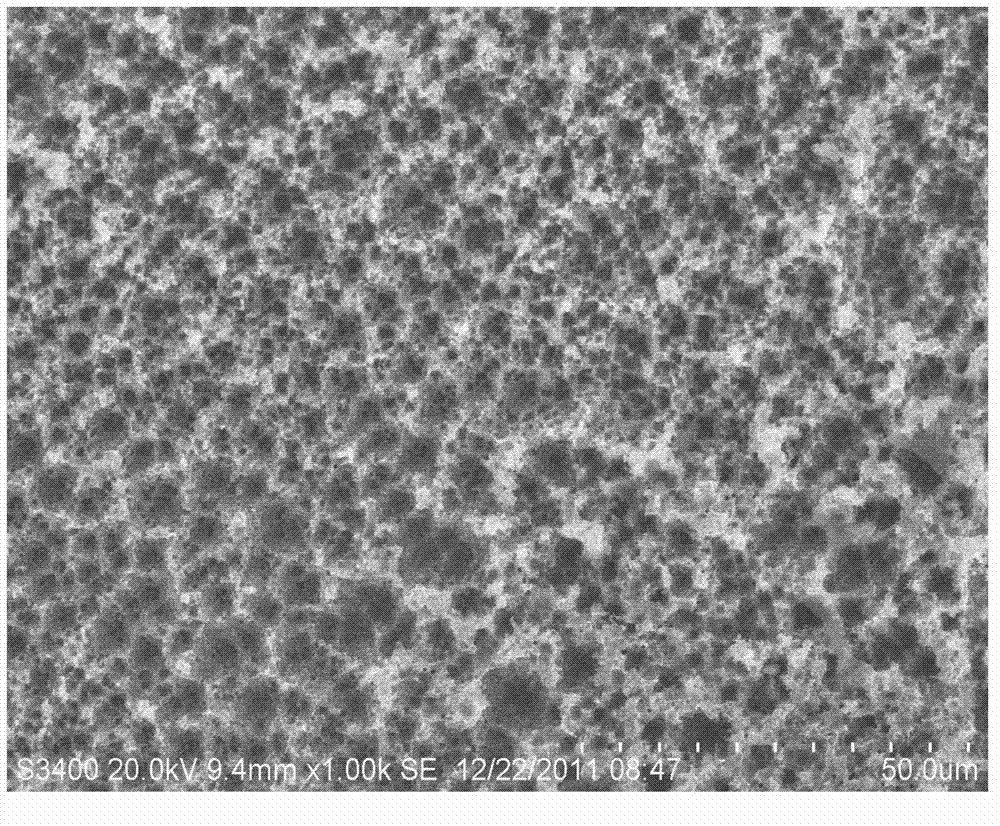

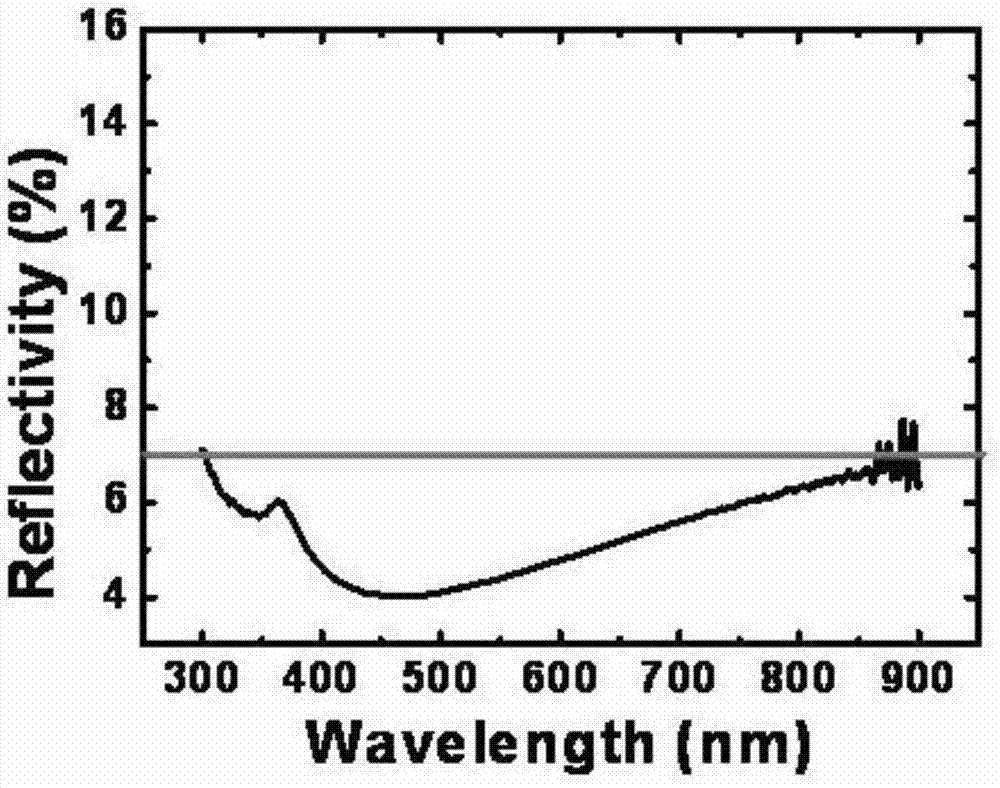

[0025] Embodiment 1: configure 100 milliliters mixed solution by the mol ratio 5:4 of hydrofluoric acid and hydrogen peroxide, wherein the concentration of hydrofluoric acid is 5 mol / L, and the concentration of hydrogen peroxide is 4 mol / L, and the concentration of copper nitrate The concentration is 0.02 mol / L. Put the unpolished polycrystalline silicon chip into the solution at room temperature or 25 ℃, take out the silicon chip after 15 minutes, wash it with concentrated nitric acid solution, rinse it with deionized water and dry it. The prepared black silicon material absorbs more than 93% of the light in the wavelength range of 300-900nm. The SEM top view of black silicon material is as follows figure 1 As shown, a relatively uniform circular microporous structure is formed on the surface of the black silicon material. figure 2 It shows that the light absorption of the black silicon material in the wavelength range of 300-900nm is as high as 93%. If the ratio of the ...

Embodiment 2

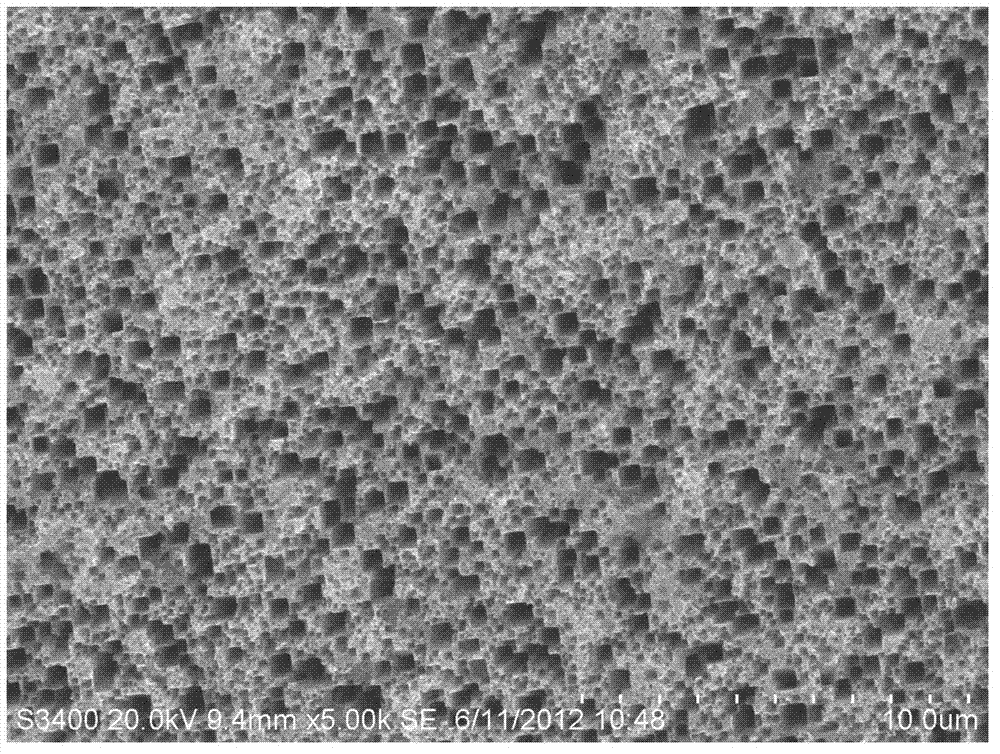

[0026] Embodiment 2: configure 100 milliliters mixed solution by the mol ratio 2:4 of hydrofluoric acid and hydrogen peroxide, wherein the concentration of hydrofluoric acid is 2 mol / L, and the concentration of hydrogen peroxide is 4 mol / L, and the concentration of copper nitrate The concentration is 0.04 mol / L. Put the unpolished polycrystalline silicon chip into the solution heated to 40 ℃, take out the silicon chip after 60 minutes, wash it with concentrated nitric acid solution, rinse it with deionized water and dry it. The prepared black silicon material absorbs more than 92% of the light in the wavelength range of 400-900nm. The SEM top view of black silicon material is as follows image 3 As shown, a relatively uniform square nanopore structure is formed on the surface of the black silicon material. Figure 4 It shows that the light absorption of the black silicon material in the wavelength range of 400-900nm is as high as 92%. The concentration of hydrofluoric acid ...

Embodiment 3

[0027] Embodiment 3: configure 100 milliliters mixed solutions by the mol ratio 5:4 of hydrofluoric acid and hydrogen peroxide, wherein the concentration of hydrofluoric acid is 5 mol / L, and the concentration of hydrogen peroxide is 4 mol / L, and the concentration of copper nitrate The concentration is 0.2 mol / L. Put the unpolished polysilicon chip into the solution cooled to 5 ℃, take out the silicon chip after 120 minutes, wash it with concentrated nitric acid or concentrated sulfuric acid solution, rinse it with deionized water and dry it. The SEM top view of black silicon material is as follows figure 1 As shown, the surface of the black silicon material forms a relatively uniform micro-hole structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com