Fabrication process of crystalline silicon solar cell

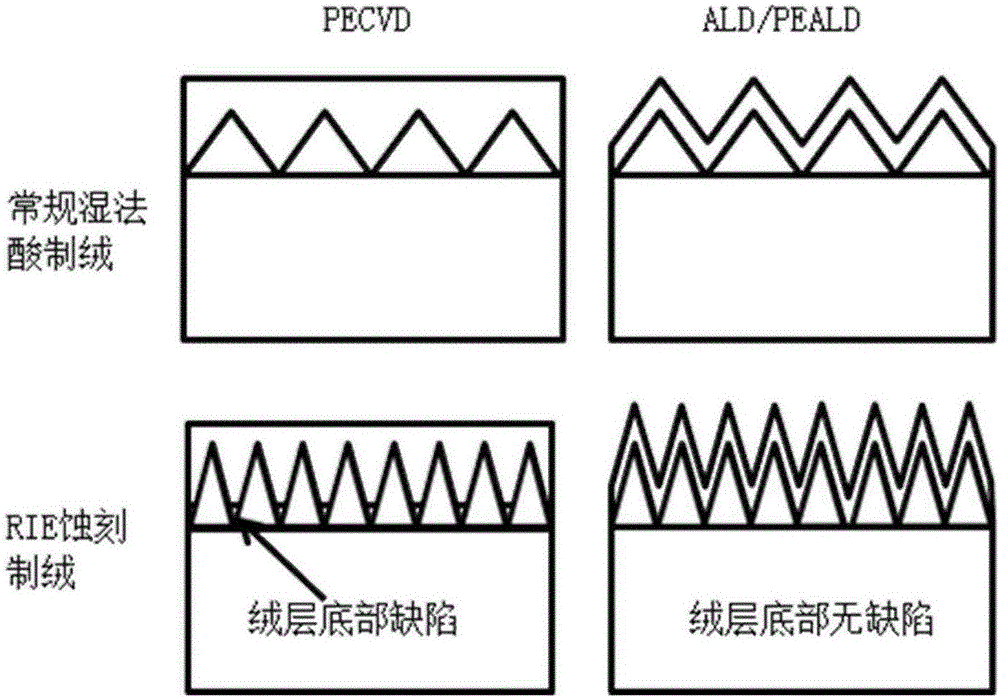

A solar cell and manufacturing process technology, applied in sustainable manufacturing/processing, final product manufacturing, semiconductor/solid-state device manufacturing, etc., can solve the problem of not being able to cover the bottom of the fleece layer, so as to improve photoelectric conversion efficiency, increase production capacity, and reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

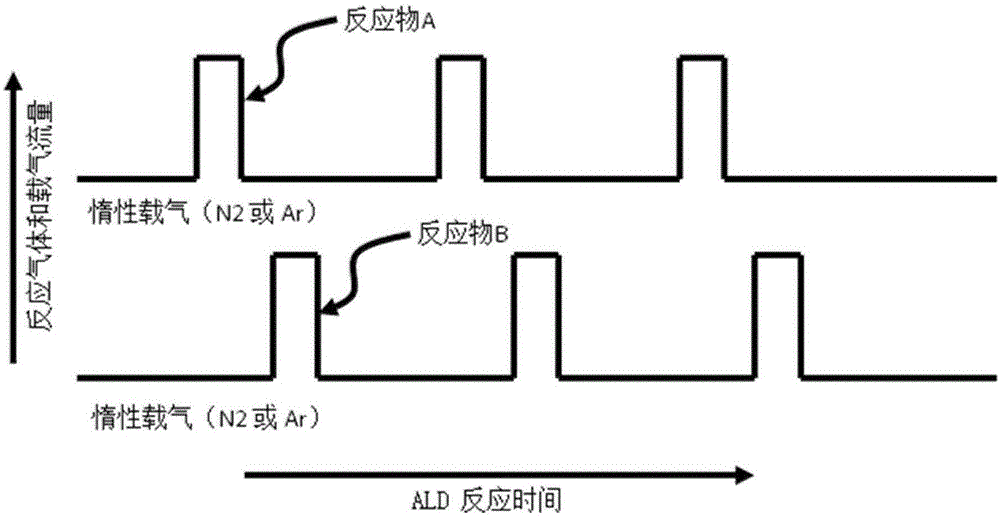

Method used

Image

Examples

Embodiment 1

[0068] Example 1 Preparation of common PERC battery anti-reflection layer and ALD passivation layer process

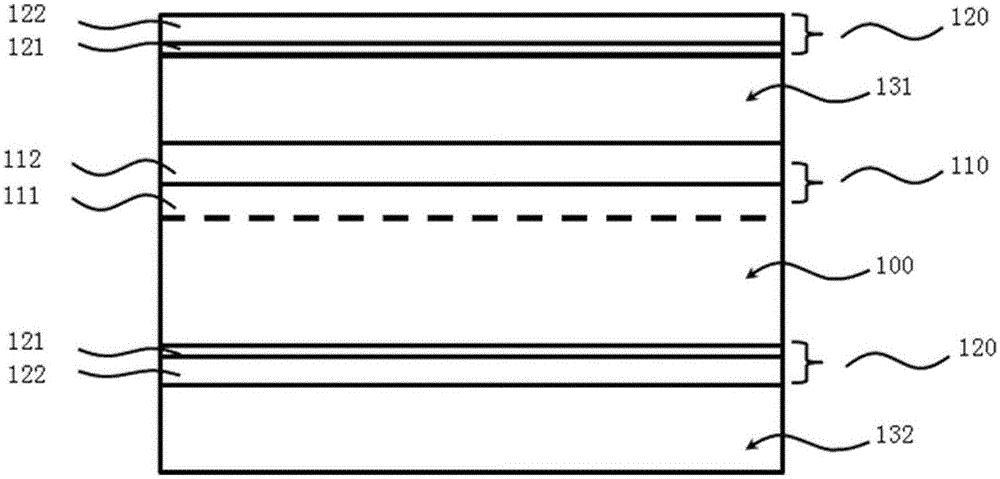

[0069] Using the present invention to firstly prepare the ordinary PERC battery structure and the anti-reflection layer, and then carry out the process of ALD technology double-sided coating passivation layer, using different reaction chambers and process parameters, SiN can be prepared x / SiO 2 / Al 2 o 3 / SiN x Composite structure, the implementation of specific process parameters and the prepared composite structure are as follows:

[0070] Table 2 Preparation of SiN x / SiO 2 / Al 2 o 3 / SiN x Composite structure( Figure 3A ) of the parameters of the specific embodiment, the specific process see Figure 4A

[0071]

[0072] Note: step 121 and step 122 perform double-sided coating at the same time in the same cavity, and step 131 and step 132 choose different cavities for PEALD or PECVD single-sided coating according to the actual situation.

[0073] Wh...

Embodiment 2

[0080] Example 2 Process for preparing ALD passivation layer and PEALD antireflection layer / protective layer of common PERC battery

[0081] Using the present invention to first prepare the double-sided coating of the ALD passivation layer of the PERC battery structure, and then perform the process of PEALD or PECVD anti-reflection layer and passivation layer, and use the same ALD / PEALD reaction chamber and process parameters to prepare SiN x / SiO 2 / Al 2 o 3 / SiN x Composite structure, the implementation of specific process parameters and the prepared composite structure are as follows:

[0082] Table 5 Preparation of SiN x / SiO 2 / Al 2 o 3 / SiN x Composite structure( Figure 3B ) of the specific embodiment of the parameters (using the same ALD / PEALD reaction chamber, the specific process is shown in Figure 4B-1 )

[0083]

[0084] Note: step 121 and step 122 perform double-sided coating at the same time in the same cavity, and step 130 performs PEALD double-si...

Embodiment 3

[0085] Example 3 Process for preparing ALD passivation layer and PEALD / PECVD antireflection layer / protective layer of common PERC battery

[0086] Using the present invention to first prepare the ALD passivation layer double-sided coating of the PERC battery structure, and then perform the process of PEALD or PECVD anti-reflection layer and passivation layer, and use different ALD / PEALD / PECVD reaction chambers and process parameters to prepare SiN x / SiO 2 / Al 2 o 3 / SiN x Composite structure, the implementation of specific process parameters and the prepared composite structure are as follows:

[0087] Table 6 Preparation of SiN x / SiO 2 / Al 2 o 3 / SiN x Composite structure( Figure 3B ) of the parameters of specific embodiments (using different ALD / PEALD / PECVD reaction chambers, see the specific process flow Figure 4B-2 )

[0088]

[0089] Note: Step 120 performs double-sided coating in the ALD chamber at the same time, and step 130 performs double-sided coati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com