Method for preparing black silicon structure by Ag-Cu (silver-copper) bimetallic MACE (metal-assisted chemical etching) type

A bi-metal, black silicon technology, applied in chemical instruments and methods, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as restricting the efficiency of black silicon cells and the inability of thin films to passivate the black silicon surface well. To achieve the effect of reducing the preparation cost, reducing the dosage, and improving the conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

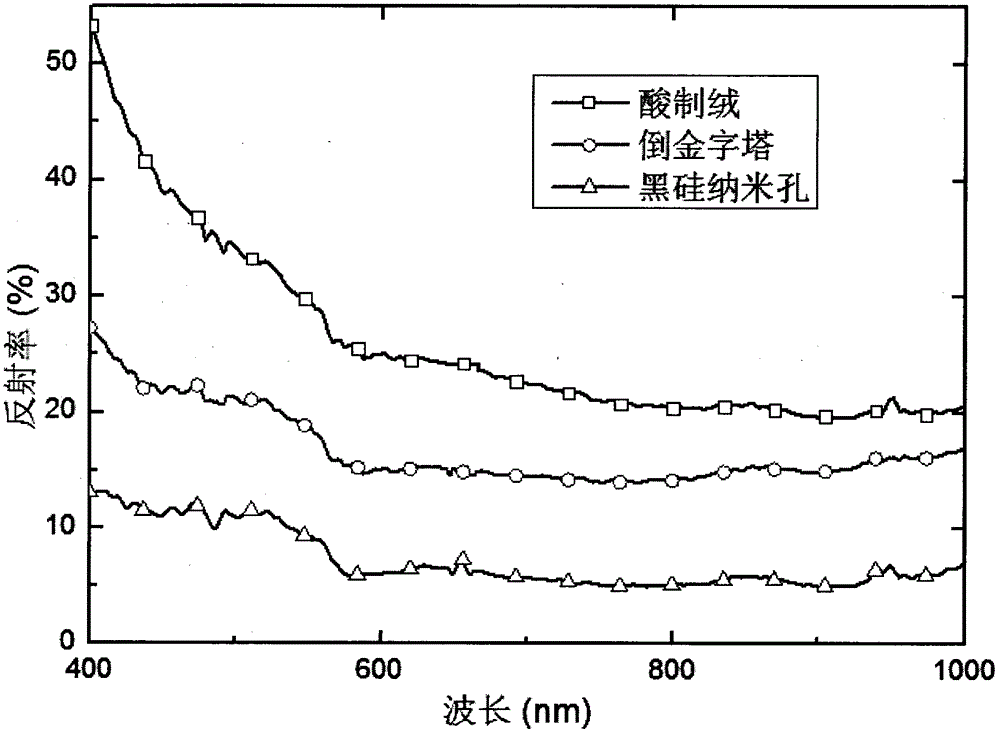

[0028]In order to control the preparation cost of black silicon and improve the conversion efficiency of black silicon cells, an embodiment of the present invention provides a low-cost silver-copper bimetallic MACE method for preparing a polycrystalline black silicon structure, including:

[0029] Clean the surface of the silicon wafer;

[0030] Using Cu(NO 3 ) 2 and AgNO 3 The MACE etching solution of bimetallic atoms catalyzes the corrosion of silicon wafers to prepare nanoporous structures;

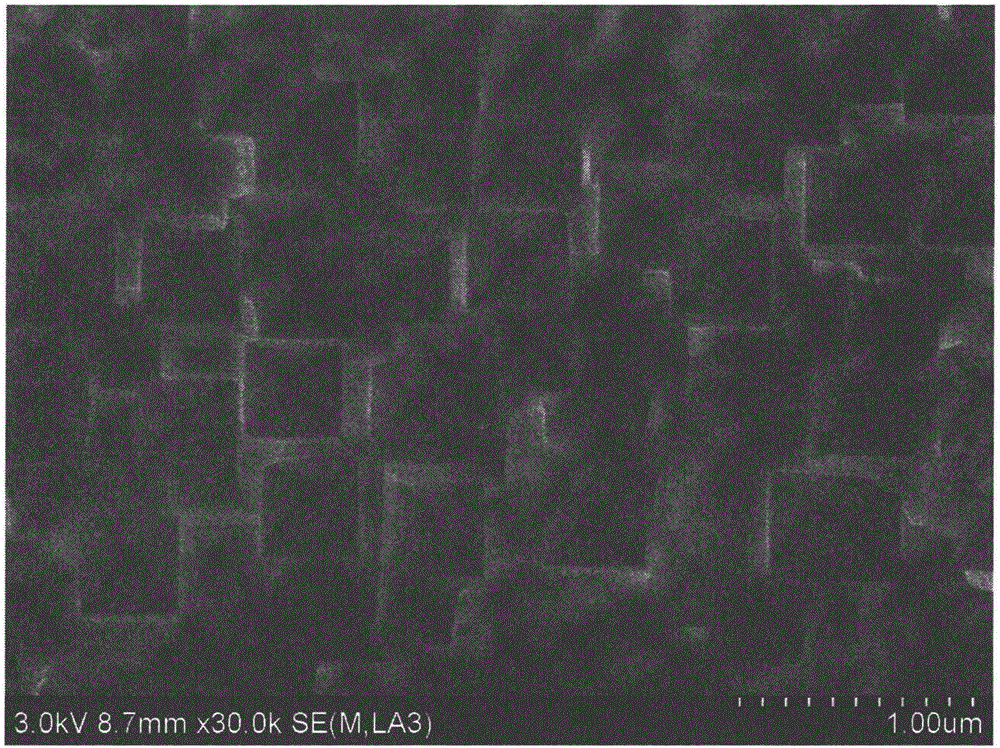

[0031] The prepared black silicon is cleaned with a nano-reconstruction solution to form an inverted pyramid anti-reflection structure on the surface of the silicon wafer.

[0032] The principle of the present invention: because the electronegativity of silicon is 1.90, when metal elements such as Ag (1.93), Cu (1.91) etc. with higher electronegativity than silicon are in contact with silicon and are in HF and H 2 o 2 When in the mixed solution of silicon, a galvanic cell will be ...

Embodiment 1

[0039] (1) First use acidic hydrogen peroxide containing sulfuric acid for acid oxidation cleaning, then use weak alkaline hydrogen peroxide containing amine for alkaline oxidation cleaning, then use dilute hydrofluoric acid solution for cleaning, and finally use hydrochloric acid Acidic hydrogen peroxide is used for acidic oxidation cleaning, rinsing with ultrapure water (DI water) in the middle of each cleaning, and finally drying with low boiling point organic solvents.

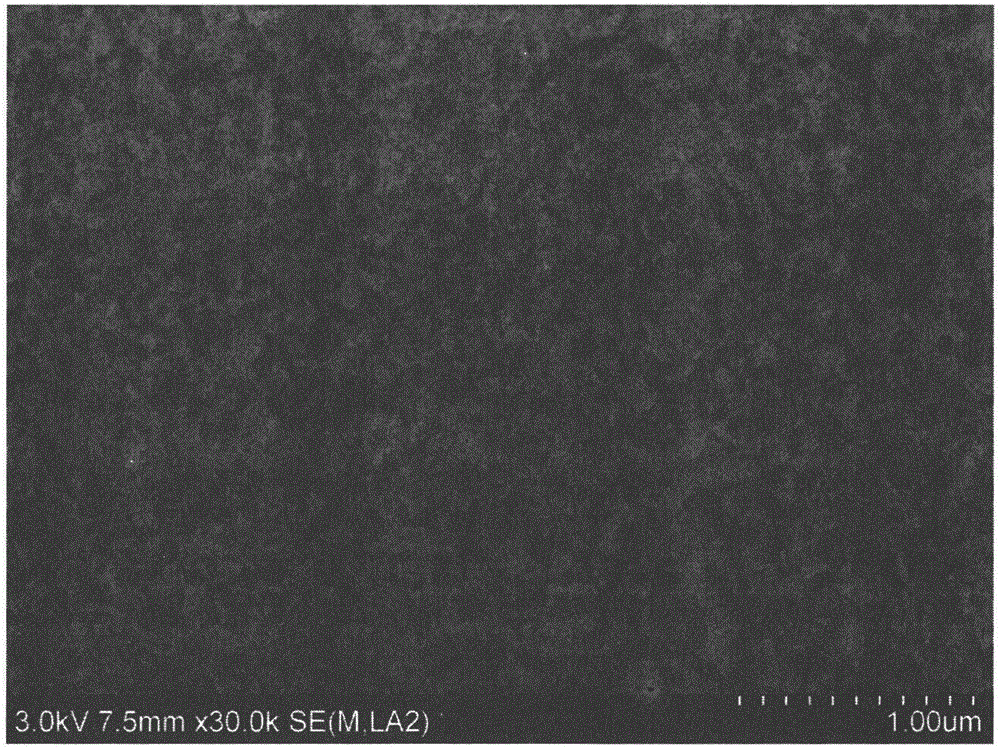

[0040] (2) Dip the cleaned silicon wafer into solution 1 for corrosion, 0.1mM AgNO 3 +24mM Cu(NO 3 ) 2 +5M HF+0.4MH 2 o 2 , controlling the molar ratio of silver and copper ions to be 1:240 to obtain nanopore and nanogroove structures, the reaction time is 180s, and the reaction temperature is room temperature;

[0041] (3) immerse the etched black silicon chip in the solution to clean, remove residual silver nanoparticles, H 2 o 2 : NH 4 OH=1:3, the reaction time is 180s;

[0042] (4) Immersing th...

Embodiment 2

[0046] (1) First use acidic hydrogen peroxide containing sulfuric acid for acid oxidation cleaning, then use weak alkaline hydrogen peroxide containing amine for alkaline oxidation cleaning, then use dilute hydrofluoric acid solution for cleaning, and finally use hydrochloric acid Acidic hydrogen peroxide is used for acidic oxidation cleaning, rinsing with ultrapure water (DI water) in the middle of each cleaning, and finally drying with low boiling point organic solvents.

[0047] (2) Dip the cleaned silicon wafer into solution 1 for corrosion, 0.1mM AgNO 3 +24mM Cu(NO 3 ) 2 +5M HF+0.4MH 2 o 2 , controlling the molar ratio of silver and copper ions to be 1:240 to obtain nanopore and nanogroove structures, the reaction time is 180s, and the reaction temperature is room temperature;

[0048] (3) immerse the etched black silicon chip in the solution to clean, remove residual silver nanoparticles, H 2 o 2 : NH 4 OH=1:3, the reaction time is 180s;

[0049] (4) Immersing th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Hole depth | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com