Silicon-avalanche photodetector (Si-APD) with black silicon as photosensitive layer and preparation method thereof

A photodetector and photosensitive layer technology, applied in the field of photodetection, can solve the problems of expensive InGaAs crystal material, limited spectral detection range, poor thermal and mechanical properties, etc., to reduce lateral dark current, improve responsivity and quantum efficiency, The effect of improving the light absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

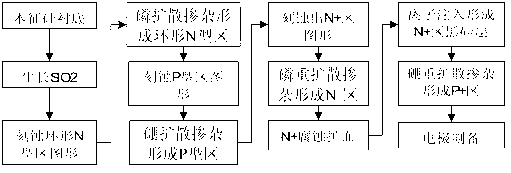

Method used

Image

Examples

Embodiment Construction

[0035] The specific implementation method of the present invention will be further described below in conjunction with the drawings and embodiments.

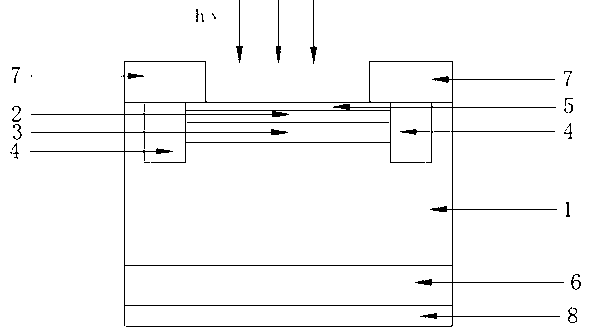

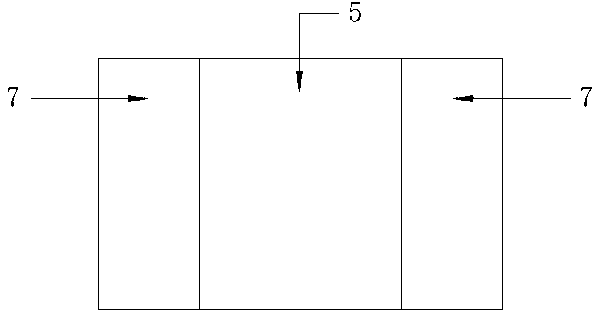

[0036] A Si-APD photodetector with black silicon as the photosensitive layer, such as figure 1 , 2 As shown, it includes silicon intrinsic substrate 1, N located in the center of the upper surface of silicon intrinsic substrate 1 + District 2, located in N + The P-type region 3 below the region 2, the ring-shaped N-type region 4 located around the upper surface of the silicon intrinsic substrate 1, and the N-type region located at the N + N on the upper surface of zone 2 + Region black silicon layer 5, P located on the lower surface of silicon intrinsic substrate 1 + District 6, located in N + The upper electrode 7 on the upper surface of the black silicon layer 5 and the ring-shaped N-type region 4 and the P + The lower electrode 8 on the lower surface of the region 6.

[0037] Among the above technical solutions:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com