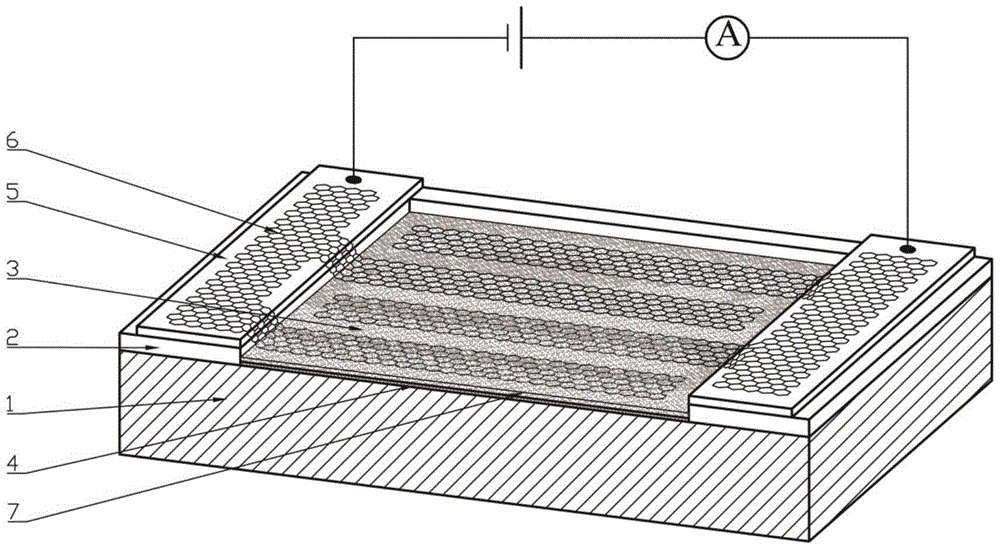

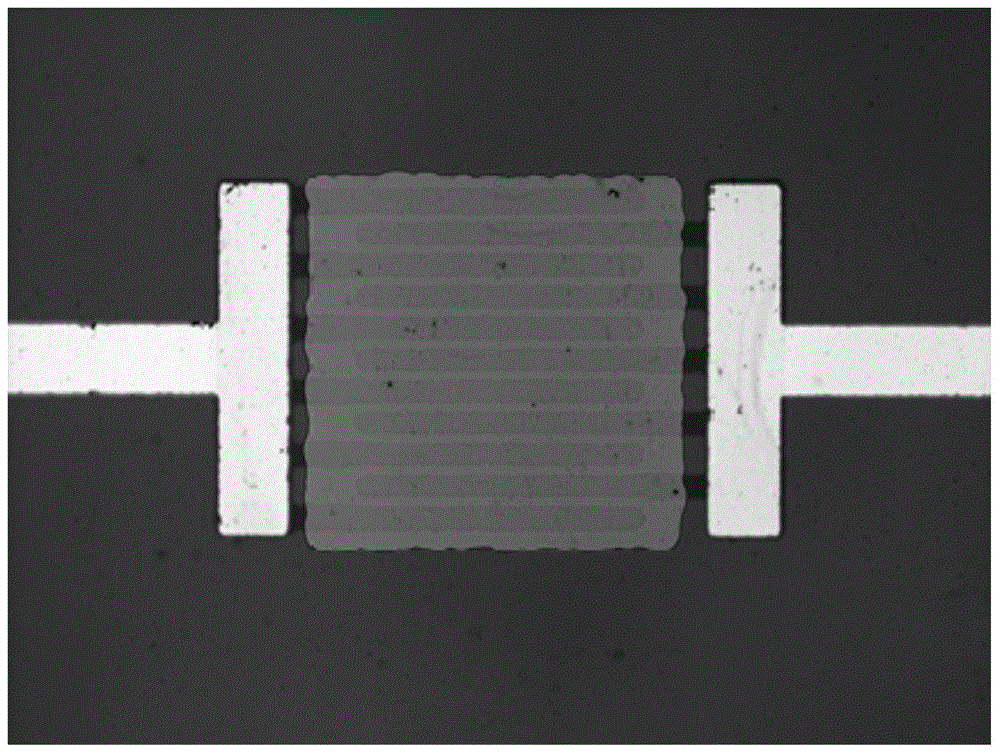

Graphene/silicon/graphene-based avalanche photodetector and its preparation method

An avalanche photoelectric and graphene technology, applied in the field of photoelectric detection, can solve problems such as ultraviolet light dead layers, and achieve the effects of improving time response, easy electric field separation, and eliminating dead layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The operating principle of the avalanche photodetector based on graphene / silicon / graphene provided by the invention is as follows:

[0031] The graphene is in contact with the n-type silicon substrate to form a Schottky junction, and the adjacent graphene interdigitated electrodes and the silicon substrate form two back-to-back Schottky junctions. After the electrodes at both ends are biased, one Schottky junction is forward biased and the other Schottky junction is reverse biased. When incident light hits the graphene / silicon interface, the graphene and silicon substrates absorb the incident light and generate electron-hole pairs. Under the action of an electric field, holes flow to the positive electrode, and electrons flow to the negative electrode, forming a photogenerated current. Graphene and silicon form a Schottky shallow junction, and the electron holes generated by the incident light are quickly separated by the electric field, reducing surface recombination ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com