Method for manufacturing non-refrigerant thermal infrared detector based on black silicon material

A non-cooling and thermal infrared technology, which is applied in the coating process of metal materials, the process for producing decorative surface effects, and the manufacture of microstructure devices, etc. It can solve the problems that infrared radiation cannot directly convert electrical signals and does not have much meaning , to achieve great application prospects and research value, low cost and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

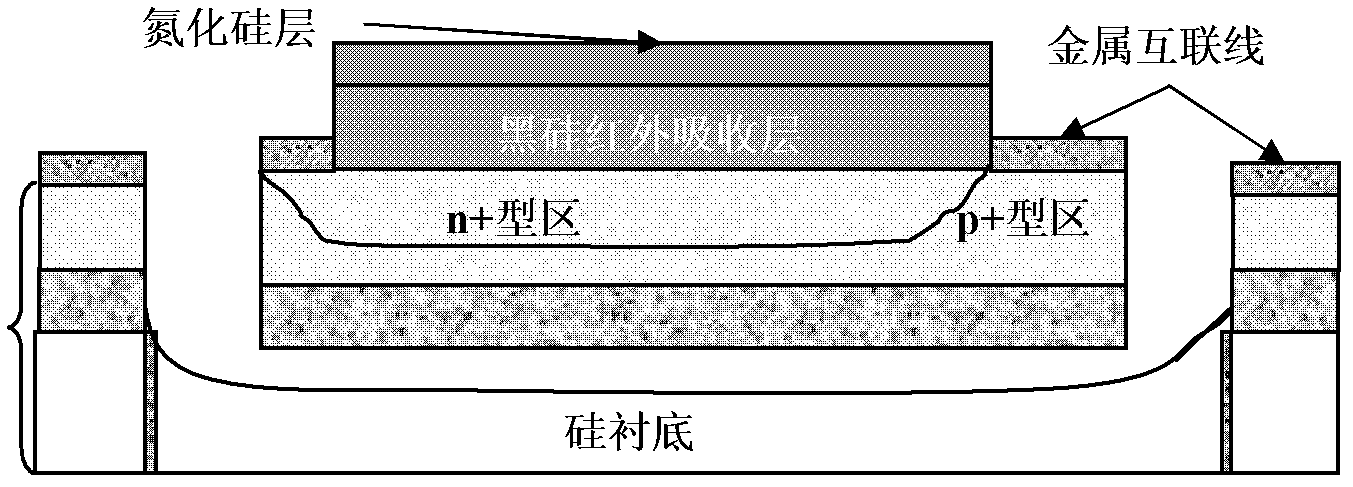

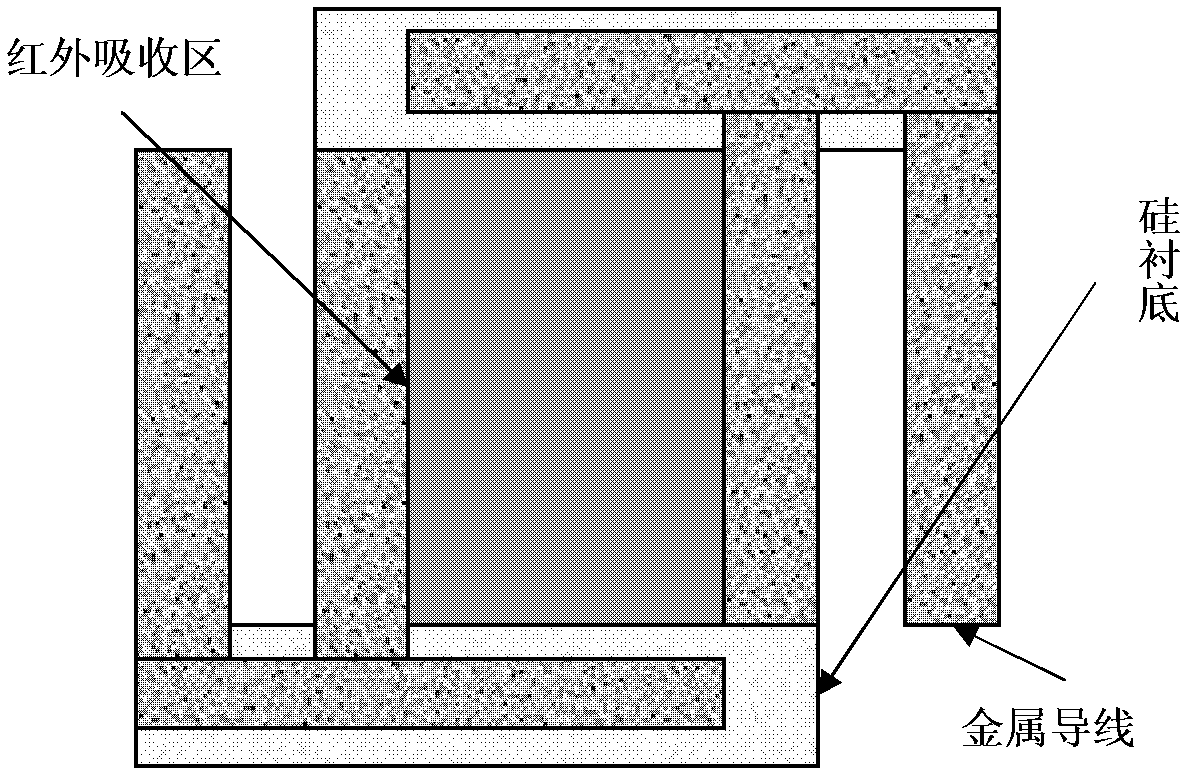

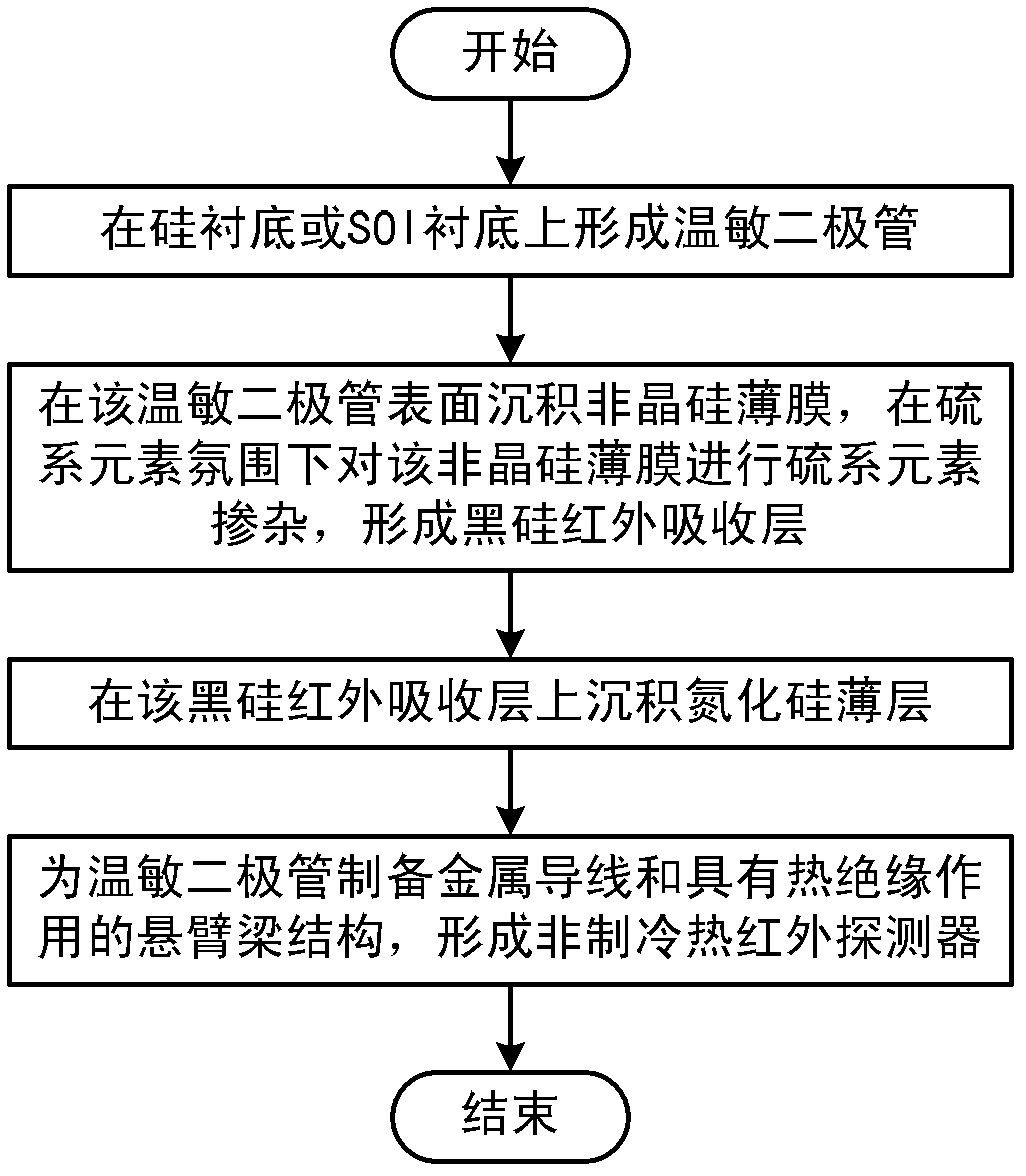

[0031] What attracts people's attention is that black silicon has an absorption effect similar to that of a black body in the full solar spectrum range, and this material is based on silicon and is also compatible with the currently commonly used CMOS and SOI-CMOS processes. However, current research has found that most of the absorption of infrared radiation by black silicon materials is caused by defect energy levels, and it is difficult to directly convert this part of the absorption into photocurrent. According to the characteristics of high infrared radiation absorption and low infrared photogenerated carrier output of the black silicon material, the invention combines the black silicon material as an infrared radiati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com