Method for manufacturing black silicon material

A technology of black silicon and silicon wafers, applied in the field of semiconductor optoelectronic materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

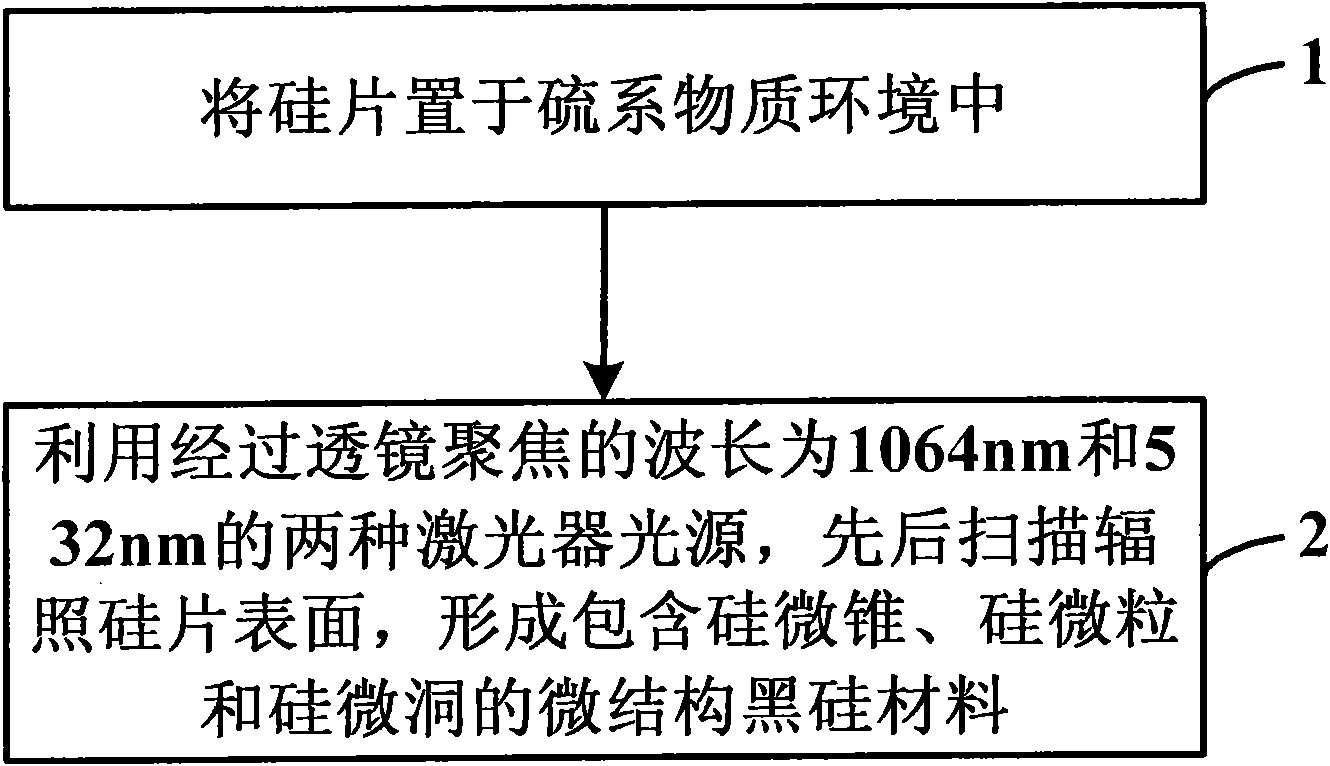

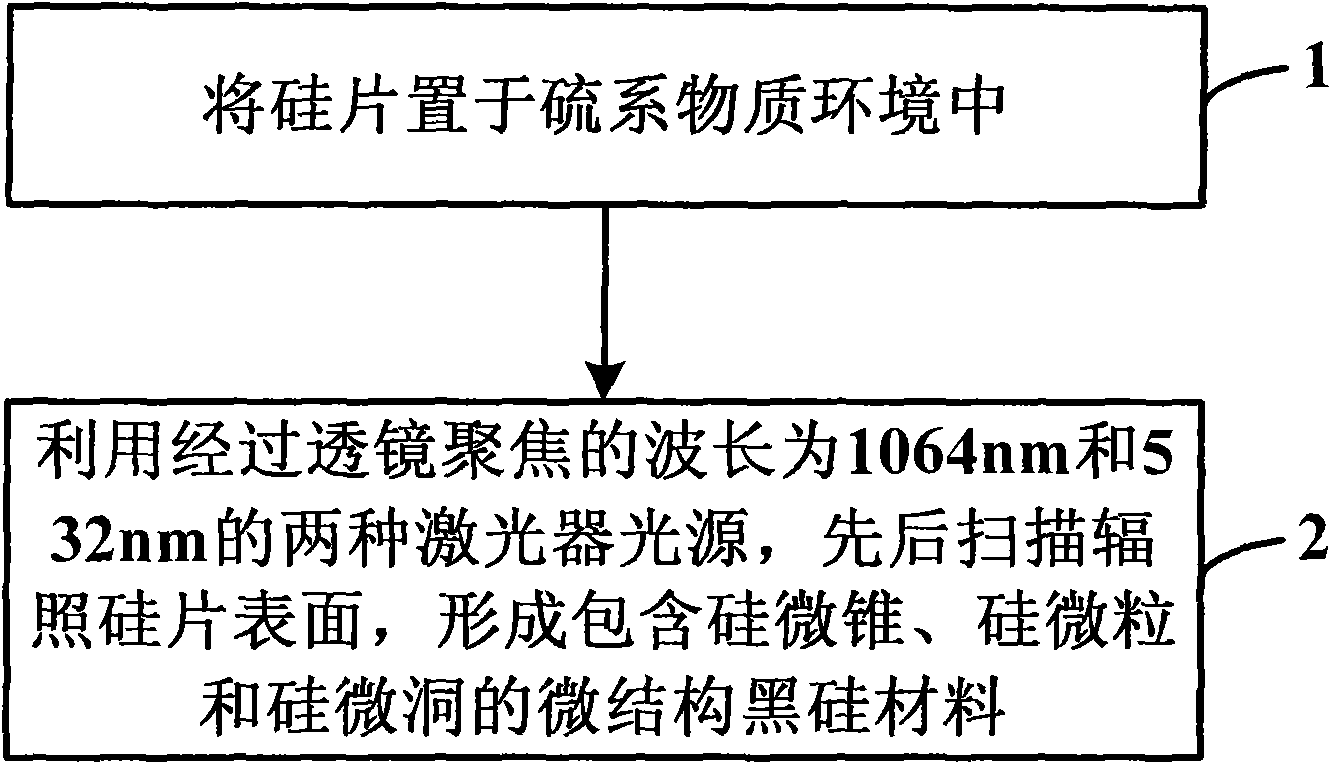

[0024] The method provided by the present invention utilizes two kinds of laser light sources with wavelengths of 1064nm and 532nm to scan and produce black silicon material, and the pulse width of the laser used is several hundred femtoseconds to several hundred nanoseconds. Place the silicon wafer in the environment of chalcogenides, scan and irradiate the silicon surface with two kinds of laser light sources with wavelengths of 1064nm and 532nm respectively, and integrate the characteristics of long-wave light source with deep action length and short-wave light source with shallow action depth into the production of black silicon materials , forming a microstructure of silicon microcones, silicon particles and silicon m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com