Thermopile infrared detector, array and preparation method of thermopile infrared detector

An infrared detector and thermopile technology, which is applied in electrical radiation detectors, piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve problems such as process incompatibility, and achieve Solve the effect of incompatibility with IC process, reduce production cost and increase absorption area

Active Publication Date: 2013-01-30

中科芯未来微电子科技成都有限公司

View PDF3 Cites 27 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, gold black coating and silver black coating are generally produced by resistance heating vacuum evaporation method, which is not compatible with IC (Integrated Circuit, integrated circuit) process

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

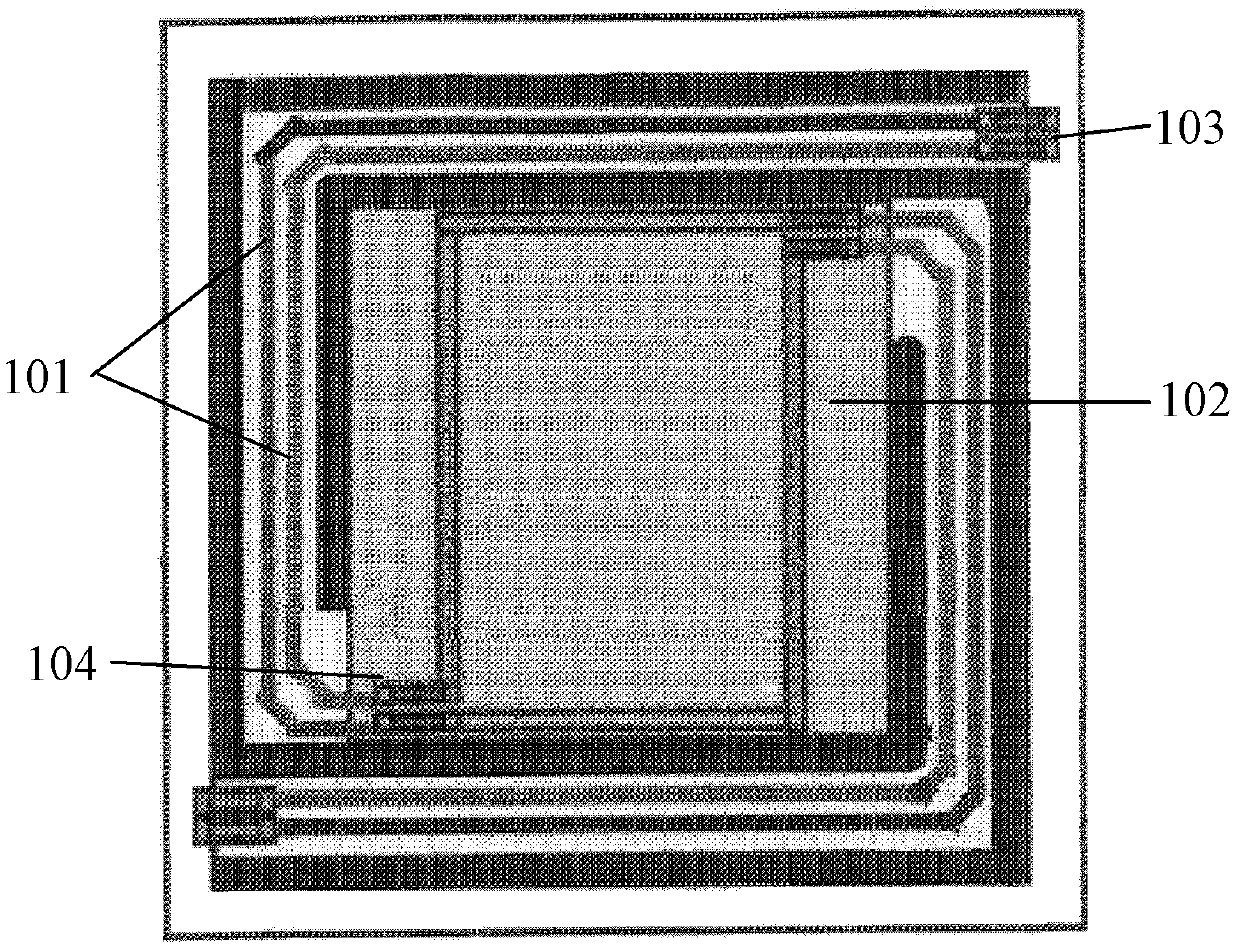

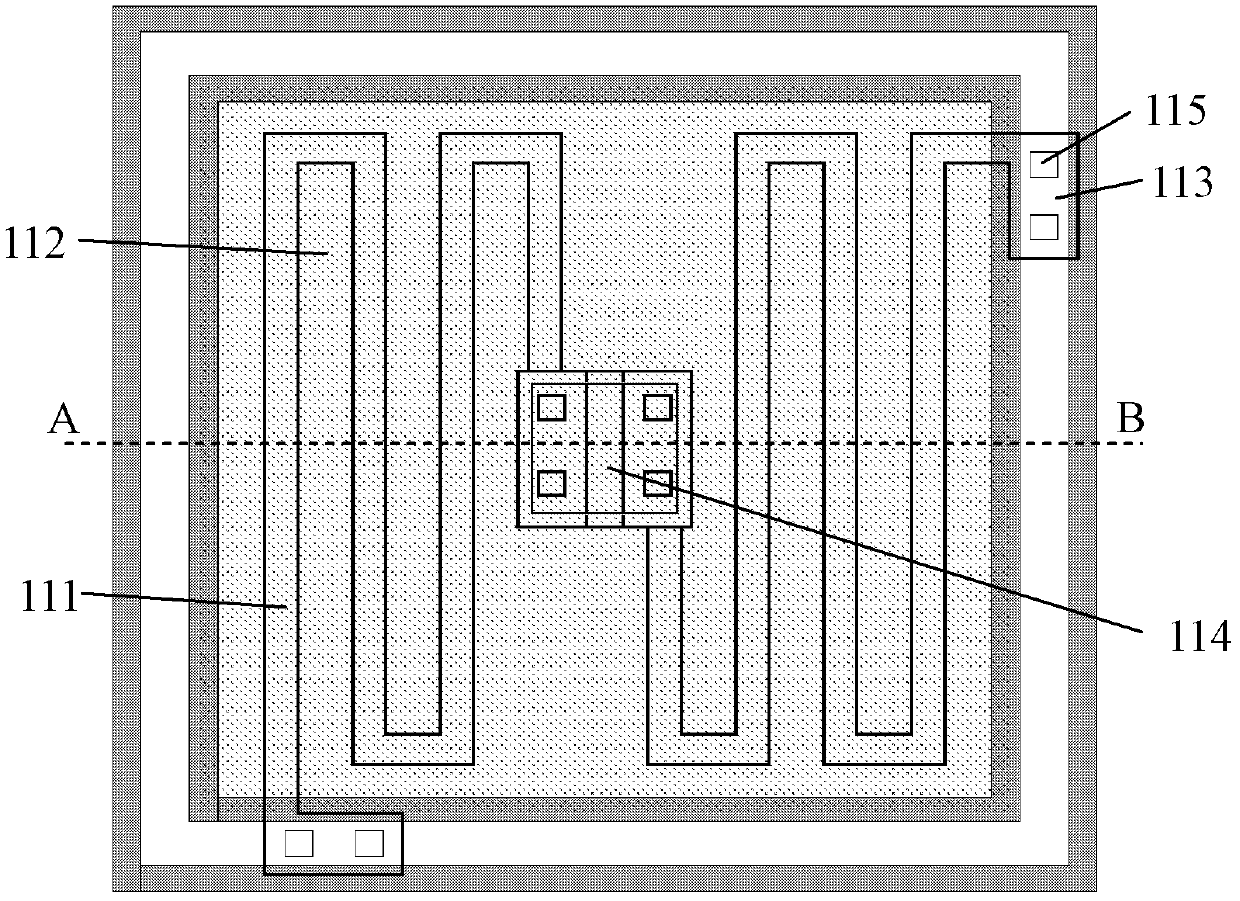

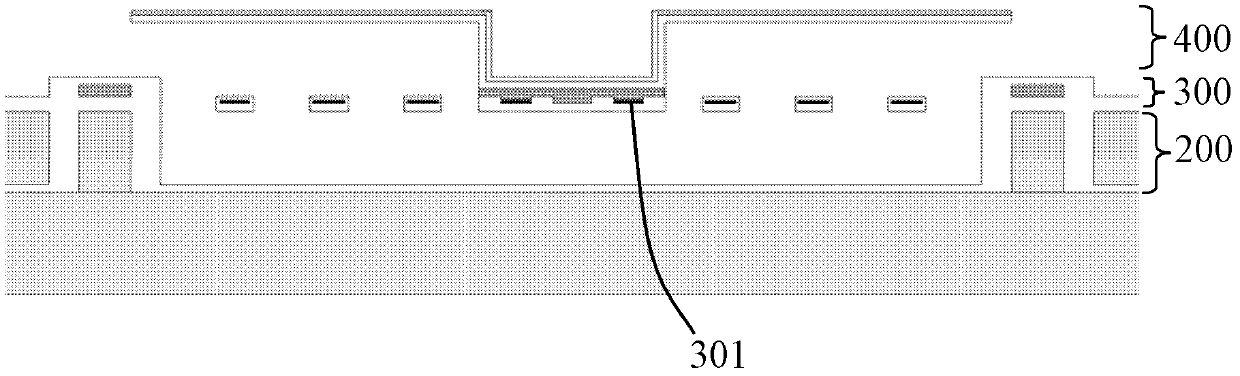

The invention provides a thermopile infrared detector and an array thereof. The thermopile infrared detector comprises a supporting part, a thermocouple part and an infrared absorption part. The supporting part comprises a supporting column and a cavity, the thermocouple part is suspended above the supporting part, a cold end of the thermocouple part is connected with the supporting column, and the infrared absorption part is positioned above the thermocouple part and connected with a hot end of the thermocouple part. Correspondingly, the invention further provides a preparation method of the thermopile infrared detector. The infrared absorption part and the thermocouple part of the thermopile infrared detector are not coplanar, the area of the infrared absorption part is unlimited by thermocouple number, and the infrared absorption part can maximally cover the whole thermocouple part, so that infrared absorption efficiency can be improved. An infrared absorption layer is made of black silicon materials, the preparation method is compatible to semiconductor IC (integrated circuit) process, and accordingly preparation cost of the detector can be lowered.

Description

technical field The invention relates to the field of infrared detectors, in particular to the field of thermopile infrared detectors. Background technique With the continuous development of infrared detection technology, infrared detectors have been used as core components in infrared temperature measurement, infrared detection, infrared alarm, infrared imaging, infrared guidance and other fields. The thermopile infrared detector is a kind of thermal detector, which mainly uses the thermoelectric effect to detect the change of the temperature of the object. A thermopile is composed of two or more thermocouples connected in series, and the thermoelectric potentials output by each thermocouple are superimposed on each other to form the thermoelectric potential of the thermopile. For common thermopile infrared detectors, an important parameter to characterize its characteristics is the responsivity, which is related to factors such as infrared absorption efficiency, detector ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01J5/12B81B3/00B81B7/04B81C1/00

CPCG01J5/12

Inventor 赵利俊欧文

Owner 中科芯未来微电子科技成都有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com