Maskless method for preparing black silicon by deep reactive ion etching

A deep reactive ion, maskless technology, applied in the process of producing decorative surface effects, nanostructure manufacturing, manufacturing microstructure devices, etc., can solve the problems of low processing efficiency, small processing area, inapplicability, etc. Low cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

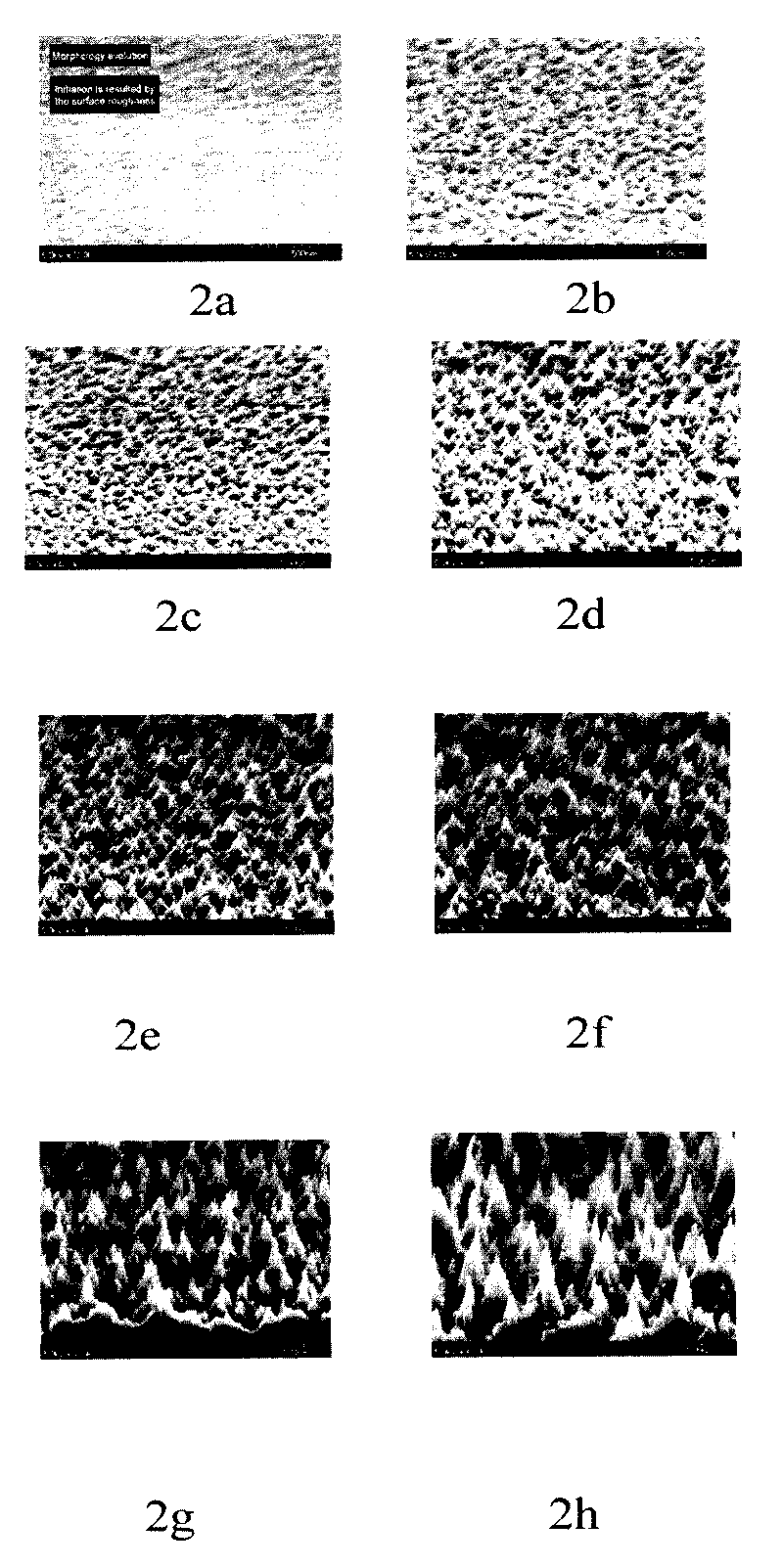

[0022] In order to make the above objects, features and advantages of the present invention more comprehensible, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

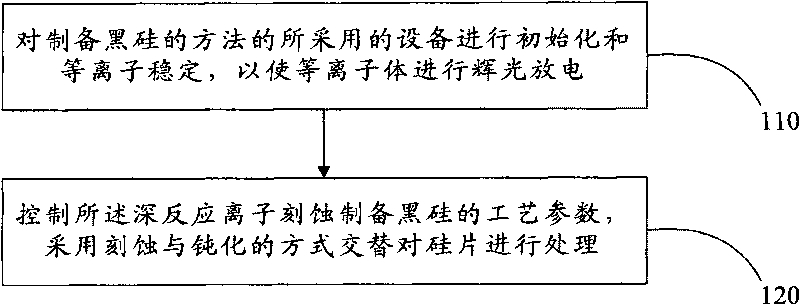

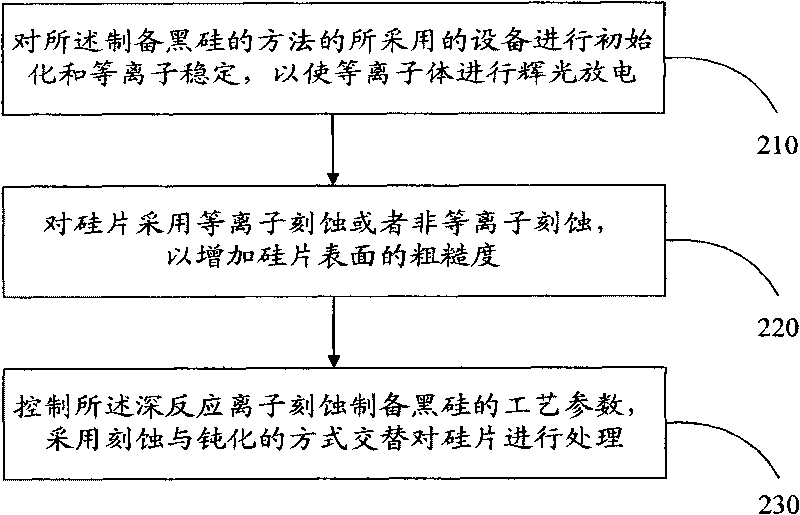

[0023] refer to figure 1 , figure 1 It is a flow chart of the steps of an embodiment of the method for preparing black silicon based on maskless deep reactive ion etching in the present invention, including the following steps:

[0024] Initialization and plasma stabilization step 110, performing initialization and plasma stabilization on the equipment used in the method for preparing black silicon, so as to make the plasma glow discharge;

[0025] The black silicon etching step 120 is to control the process parameters of the deep reactive ion etching to prepare black silicon, and alternately process the silicon wafer by means of etching and passivation; wherein, the parameters include: plasma gas fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com