Back-illuminated Si-PIN photoelectric detector taking black silicon material as photosensitive layer and manufacturing method thereof

A photodetector and photosensitive layer technology, applied in the field of photoelectric detection, can solve the problems of poor thermomechanical properties, poor crystal quality, and high price, and achieve the effects of low cost, high light absorption rate, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

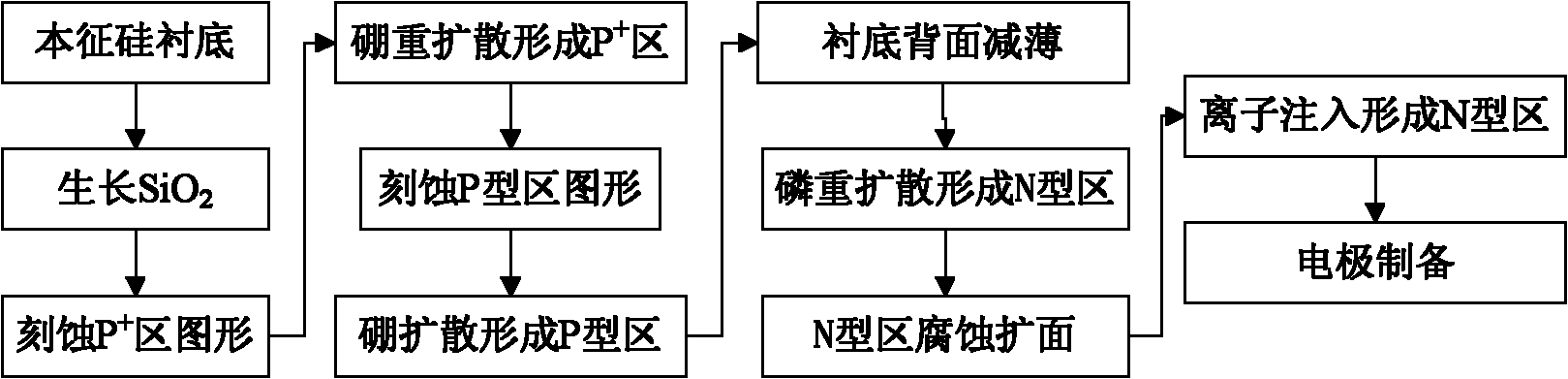

[0022] The specific implementation method of the present invention will be further described below in conjunction with the drawings and embodiments.

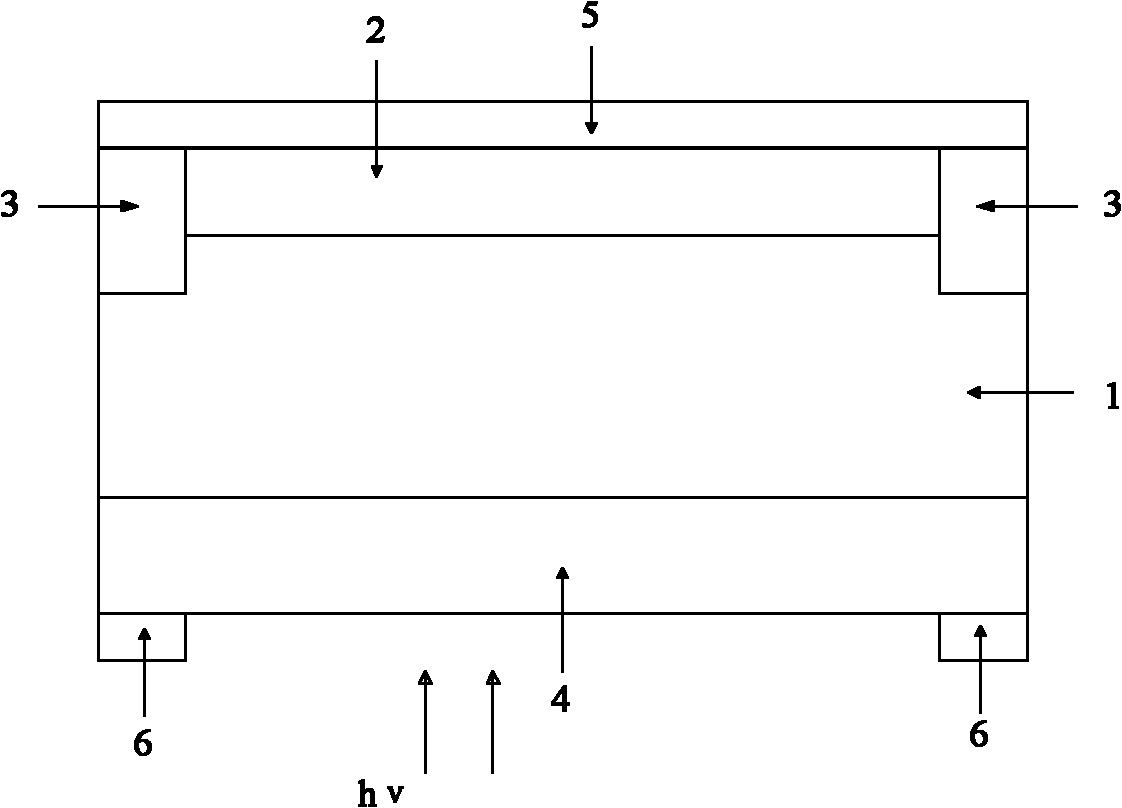

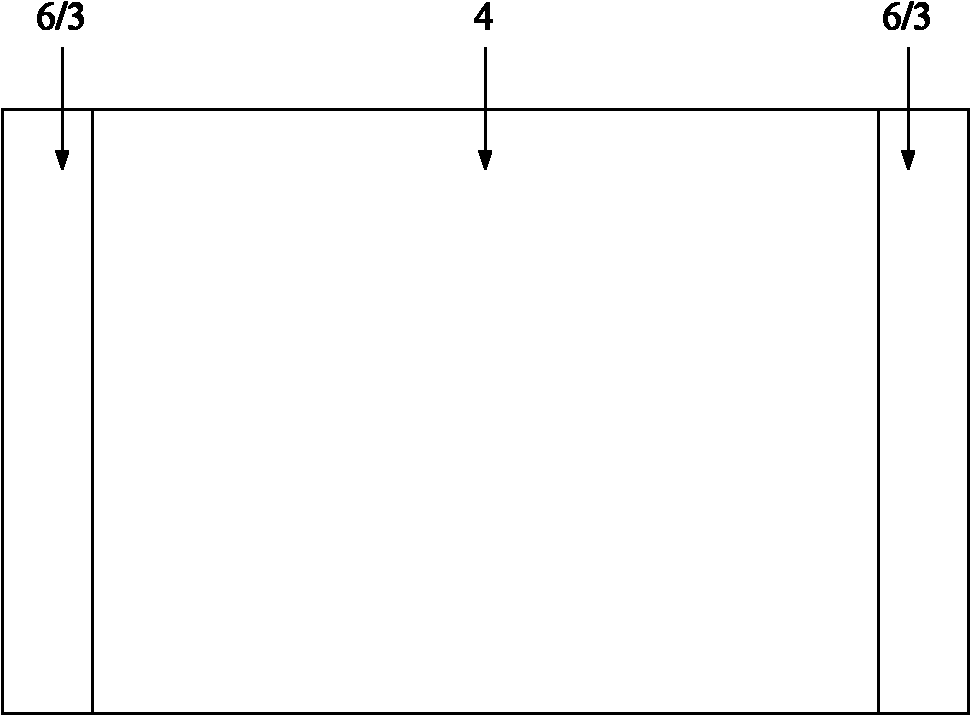

[0023] A back-illuminated Si-PIN photodetector with black silicon material as the photosensitive layer, such as figure 1 , 2 As shown, it includes a silicon intrinsic substrate 1, a P-type region 2 located in the center of the front surface of the silicon intrinsic substrate 1, and an annular P-type region located around the front surface of the silicon intrinsic substrate 1. + Region 3, N-type black silicon layer 4 located on the back side of silicon intrinsic substrate 1, located in P-type region 2 and P + The upper electrode 5 on the upper surface of the region 3, and the lower electrodes 6 located on both sides of the lower surface of the N-type black silicon layer 4; wherein P + The junction depth of region 3 is greater than the junction depth of P-type region 2 .

[0024] Among the above technical solutions:

[0025] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com