A Mismatch Layer Cobalt Oxide Pyroelectric Thin Film Photodetector

A pyroelectric thin film and photodetector technology, which is applied in the field of high-sensitivity broadband photodetectors, can solve the problems of not seeing photodetectors, and achieve the effects of high response sensitivity, simple preparation, and wide response band

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

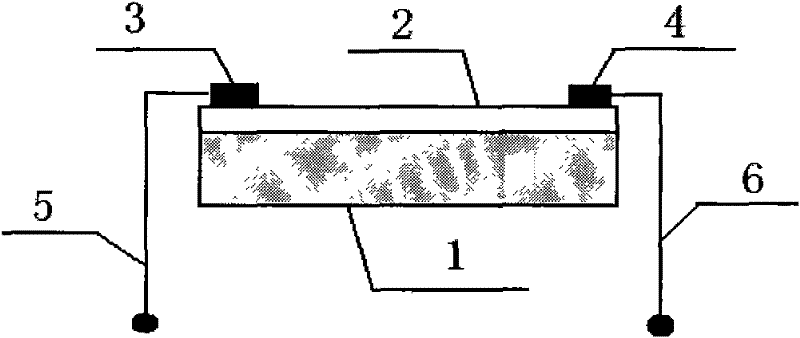

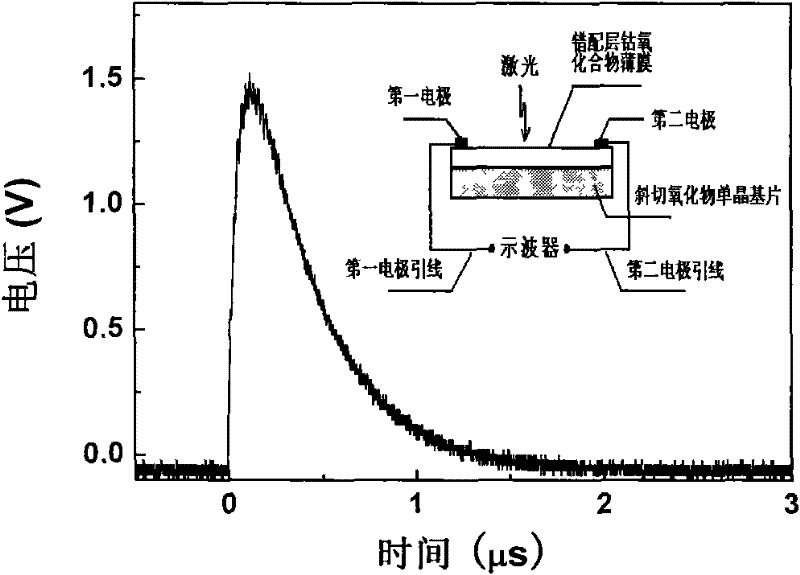

[0024] Embodiment 1: the Bi that can output laser detection to the 308nm XeCl excimer laser with a pulse width of 25ns 2 Sr 2 co 2 o 8 Thin-film photodetectors.

[0025] 1. Select the known pulsed laser deposition technology in the c-axis orientation LaAlO tilted at 10 degrees 3 Preparation of a layer of c-axis-oriented Bi with a thickness of 200 nm on a single crystal substrate 2 Sr 2 co 2 o 8 Thermoelectric thin film;

[0026] 2. Utilizing known thermal evaporation methods in Bi 2 Sr 2 co 2 o 8 Prepare two Ag electrodes on the surface of the film, the diameter of the electrodes is 0.5mm, and the distance between the electrodes is 5mm;

[0027] 3. Use conductive silver glue to stick two copper wires with a diameter of 0.1mm on the two silver electrodes respectively as the leads of the two electrodes;

[0028] 4. Connect the other ends of the two electrode leads to the oscilloscope as the output voltage signal test terminal, and the input impedance of the oscillos...

Embodiment 2

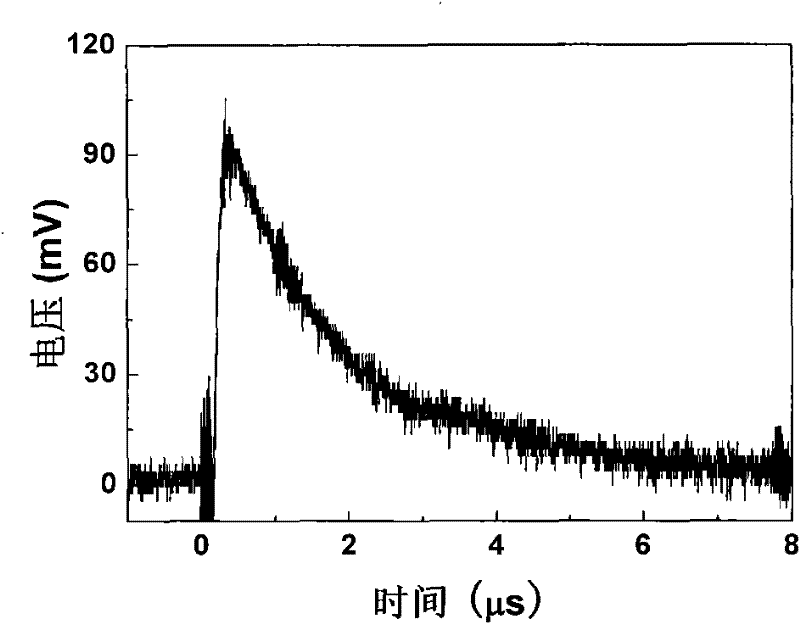

[0031] Example 2: Ca that can be detected by a 308nm XeCl excimer laser with a pulse width of 25ns 3 co 4 o 9 Thin-film photodetectors.

[0032] 1. Select the known chemical solution deposition technology at 20 degrees inclined c-axis orientation of Al 2 o 3 A layer of c-axis-oriented Ca with a thickness of 300 nm was prepared on a single crystal substrate 3 co 4 o 9 Thermoelectric thin film;

[0033] 2. With step 2-4 in embodiment 1;

[0034] 5. Use a 500M oscilloscope, use the above Ca 3 co 4 o 9 Thin-film photodetector, measuring the voltage signal output of the excimer XeCl laser (output wavelength: 308nm, pulse width: 25ns) irradiated on the detector.

[0035] image 3 It is the waveform diagram of the output voltage signal generated when the 308nm XeCl laser is irradiated on the surface of the detector recorded by the oscilloscope. It can be seen that when the laser energy irradiated on the thin film is 1mJ, the amplitude of the output voltage signal is as hig...

Embodiment 3

[0036] Embodiment 3: the Bi that can be detected by the Nd:YAG laser output laser (output wavelength is 532nm) to the pulse width of 25ps 2 Sr 2 co 2 o 8 Thin-film photodetectors.

[0037] 1. Select the known chemical solution deposition technology at 5 degrees inclined c-axis orientation of LaAlO 3 Preparation of a layer of c-axis-oriented Bi with a thickness of 150 nm on a single crystal substrate 2 Sr 2 co 2 o 8 Thermoelectric thin film;

[0038] 2. Prepare two In electrodes on the surface of the film by using a known thermal evaporation method, the diameter of the electrodes is 0.3mm, and the distance between the electrodes is 8mm;

[0039] 3. Use solder to weld two copper wires with a diameter of 0.1mm on the two In electrodes respectively as the leads of the two electrodes;

[0040] 4. Connect the other ends of the two electrode leads to the oscilloscope as the output voltage signal test terminal, and the input impedance of the oscilloscope is selected as 50 ohm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com