Nanocarbon material composite biomass hard carbon electrode material and preparation method and application thereof

A technology of electrode materials and nano-carbon materials, applied in the field of electrochemical energy storage, can solve the problems of large irreversible capacity of biomass hard carbon, reduction of material active sites, low discharge voltage, etc., and achieve fast electron migration, storage or adsorption The effect of large amount of ions or electrons and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

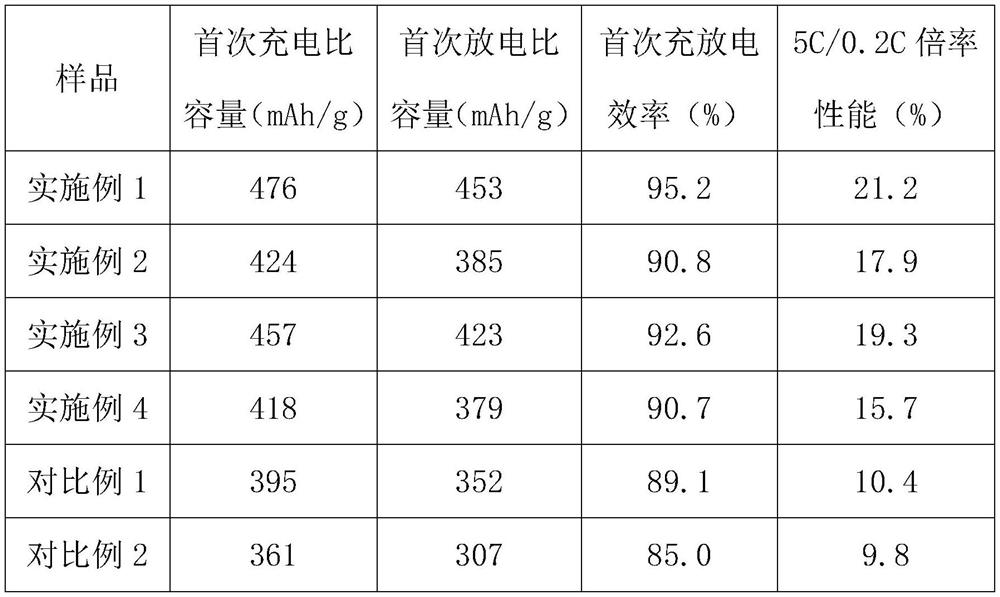

Examples

preparation example Construction

[0024] The preparation method of a kind of nano-carbon material composite biomass hard carbon electrode material of the present invention, comprises the following steps:

[0025] a. Clean the biomass raw materials such as coconut shells, straws, bamboo stalks, and tobacco stalks, and dry them at 60-120°C. After drying, perform preliminary crushing to obtain 16-60 mesh particles A;

[0026] b. Put particle A into potassium hydroxide, sodium hydroxide or ammonia solution with a concentration of 1-5mol / L, heat and stir at 90-120°C for 1-12h, then rinse with deionized water, filter or centrifuge Until the mixed liquid is neutral, then carry out solid-liquid separation, dry the solid matter at 60-120°C after separation, and perform the second crushing to obtain 100-400 mesh powder B;

[0027] c. Put powder B into hydrochloric acid or nitric acid solution with a concentration of 1-5mol / L, heat and stir at 90-120°C for 1-12h, then rinse with deionized water, filter or centrifuge unti...

Embodiment 1

[0037] This embodiment provides a nano-carbon material composite biomass hard carbon electrode material, the preparation method is as follows:

[0038] a, clean the coconut shell, and after vacuum drying at 60°C, crush with a crusher to obtain 30 mesh particles A;

[0039] b. Put particle A into an aqueous solution of potassium hydroxide with a concentration of 1 mol / L, heat and stir at 100°C for 6 hours, then repeatedly wash and centrifuge with deionized water until the mixed solution is neutral, and then perform solid-liquid separation. Vacuum-dry the solid matter at 60°C, and crush it for the second time with a crusher to obtain 100 mesh powder B;

[0040] c. Put the powder B into the nitric acid solution with a concentration of 1mol / L, heat and stir at 100°C for 6h, then repeatedly wash and centrifuge with deionized water until the mixed solution is neutral, and then separate the solid and liquid at 60°C Dry the solid substance under vacuum to obtain powder C;

[0041] D...

Embodiment 2

[0047] This embodiment provides a nano-carbon material composite biomass hard carbon electrode material, the preparation method is as follows:

[0048] a. Clean the stalks, dry them with a blast at 100°C, and then use a crusher to perform preliminary crushing to obtain 50-mesh particulate matter A;

[0049] b. Put particle A into an aqueous sodium hydroxide solution with a concentration of 2 mol / L, heat and mechanically stir at 90°C for 2 hours, then repeatedly rinse with deionized water and filter with suction until the mixed solution is neutral, and then perform solid-liquid separation. Blast-dried solid matter at 100°C, and crushed for the second time with a crusher to obtain 150-mesh powder B;

[0050] c. Put the powder B into the hydrochloric acid solution with a concentration of 2mol / L, heat and mechanically stir at 90°C for 2 hours, then repeatedly rinse with deionized water and filter with suction until the mixed solution is neutral, and then perform solid-liquid separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com