Preparation method of carbon nanotube amidation grafted polysilsesquioxane flame retardant

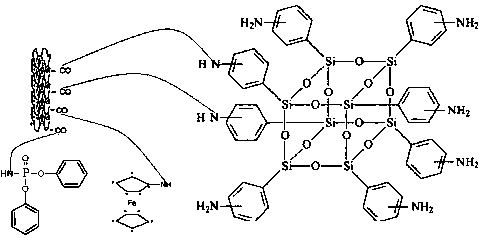

A polysilsesquioxane and carbon nanotube technology is applied in the field of preparation of carbon nanotube amidation-grafted polysilsesquioxane flame retardants, which can solve the problem of affecting the mechanical properties of substrates and poor compatibility of substrates. , large amount of flame retardants, etc., to achieve the effect of significant synergy, good compatibility and excellent flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

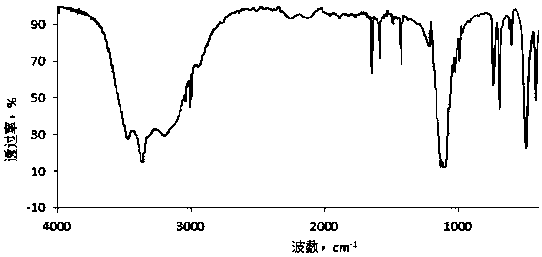

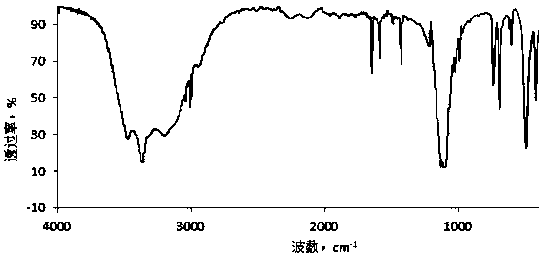

Method used

Image

Examples

Embodiment 1

[0021] 32 parts of octaaminophenyl silsesquioxanes are added to the reactor, and then under the protection of nitrogen, 1800 parts of surface acyl chloride modified carbon nanotube carbon tetrachloride dispersions with a mass percentage content of 10% are added, 10 parts of biphenyl phosphoramidate, 0.2 parts of aminoferrocene, 3.5 parts of sodium carbonate, stir and mix evenly, reflux reaction for 12 hours, after vacuum distillation, the residue is washed with 25% methanol aqueous solution, and vacuum dried The described carbon nanotube amidation grafted polysilsesquioxane flame retardant is obtained.

[0022] The carbon nanotubes are industrial-grade multi-walled carbon nanotubes with a content of ≥90%.

[0023] The preparation method of the surface acid chloride modified carbon nanotube material is as follows:

[0024] According to the number of parts by mass, 4 parts of carbon nanotubes were added to 100 parts of hydrofluoric acid solution with a mass percentage content o...

Embodiment 2

[0027] 35 parts of octaaminophenyl silsesquioxanes are added to the reactor, and then under the protection of nitrogen, 1900 parts of surface acyl chloride modified carbon nanotube carbon tetrachloride dispersions with a mass percentage content of 12% are added, 12 parts of biphenyl phosphoramidate, 0.8 parts of aminoferrocene, 4.2 parts of sodium carbonate, stir and mix evenly, reflux reaction for 18 hours, after vacuum distillation, the residue is washed with 25% methanol aqueous solution, and vacuum dried The described carbon nanotube amidation grafted polysilsesquioxane flame retardant is obtained.

[0028] The carbon nanotubes are industrial-grade multi-walled carbon nanotubes with a content of ≥90%.

[0029] The preparation method of the surface acid chloride modified carbon nanotube material is as follows:

[0030]According to the number of parts by mass, 8 parts of carbon nanotubes were added to 100 parts of hydrofluoric acid solution with a mass percent content of 15...

Embodiment 3

[0033] 43 parts of octaaminophenyl silsesquioxanes are added to the reactor, and then under the protection of nitrogen, 2400 parts of surface acyl chloride modified carbon nanotube carbon tetrachloride dispersions with a mass percentage content of 15% are added, 15 parts of biphenyl phosphoramidate, 1.5 parts of aminoferrocene, 5 parts of sodium carbonate, stir and mix evenly, reflux reaction for 24 hours, after vacuum distillation, the residue is washed with 25% methanol aqueous solution, and vacuum dried The described carbon nanotube amidation grafted polysilsesquioxane flame retardant is obtained.

[0034] The carbon nanotubes are industrial-grade multi-walled carbon nanotubes with a content of ≥90%. The preparation method of the surface acid chloride modified carbon nanotube material is as follows:

[0035] According to the number of parts by mass, 10 parts of carbon nanotubes were added to 100 parts of hydrofluoric acid solution with a mass percentage content of 20% for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com