A kind of graphene radiation heating film and its preparation method and application

A graphene and heating film technology, applied in graphene radiation heating film and its preparation and application fields, can solve the problems of non-folding or cutting, fast material decay speed, high power of heating material, etc. Utilization rate, the effect of improving thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

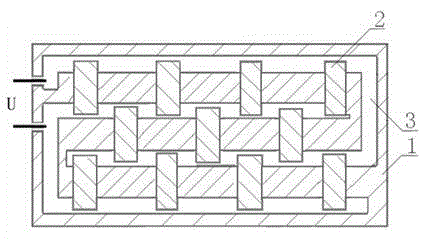

Image

Examples

Embodiment 1

[0016] Outsourcing:

[0017] Graphene powder, specifications: powder, particle size: 30-60nm.

[0018] Infrared emitter, specification: powder.

[0019] High temperature resistant phenolic resin, specification: liquid.

[0020] Weigh 4 parts of graphene powder, 2 parts of far-infrared emitter, and 5 parts of high-temperature-resistant phenolic resin, mix the graphene powder and far-infrared emitter and stir evenly, then add bonding diluent and mix to form a slurry.

Embodiment 2

[0022] Apply the slurry described in Example 1 evenly to the film formed on one surface of the fiber fabric, and dry (or dry) to form a graphene radiation heating film.

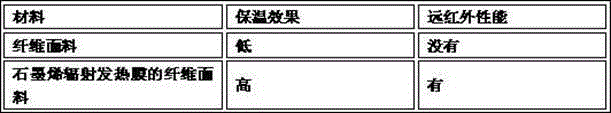

[0023] The fiber fabric containing the graphene radiation heating film and the same fiber fabric without the graphene radiation heating film were simultaneously carried out under the condition of simulated body temperature (37°C) to compare the heat preservation and radiation effects of the heat source, as shown in Table 1:

[0024] Table 1:

[0025]

[0026] The results prove that the graphene radiative heating film can radiate heat and is used to make bed sheets, quilt covers or underwear. Under the action of a heat source, it can radiate infrared wavelengths of 8-14um, and has a good heat preservation effect.

Embodiment 3

[0028] The fiber fabric containing the graphene radiation heating film obtained in Example 2, in the absence of a heat source, is only stimulated by the external environment temperature to generate heat, which emits little heat and also has a small amount of infrared wavelength radiation of 8-14um.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com