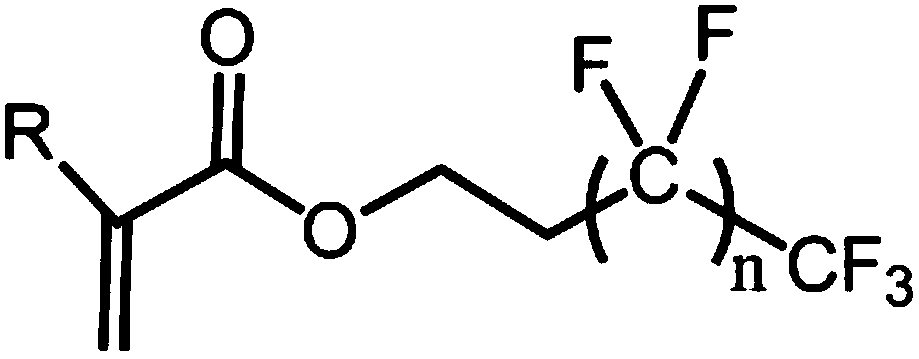

Fluorine-containing acrylate-based random copolymer, preparation method and uses thereof

A technology of random copolymers and acrylates, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as high viscosity of the system, coating defects, and affecting paint film performance, and achieve strong foam suppression and rapid elimination The effect of foam performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

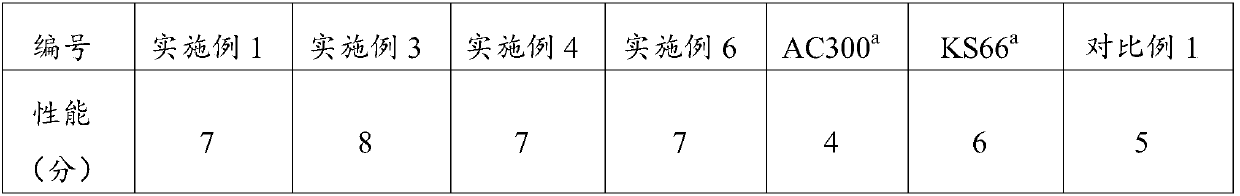

Examples

preparation example Construction

[0046] The present invention also provides a method for preparing a fluorine-containing acrylate random copolymer, comprising the following steps:

[0047] S1, heat up the solvent to 80-140°C;

[0048] Specifically, first add a suitable solvent into a four-necked flask equipped with a thermometer, mechanical stirring, and a condenser, blow nitrogen into it, and raise the temperature of the solvent to 80-140°C.

[0049] Further, in step S1, the solvent is selected from ethyl acetate, butyl acetate, octyl acetate, isooctyl acetate, propylene glycol methyl ether acetate, DBE, toluene, xylene, mesitylene, white oil one or several.

[0050] S2. Mix the monomer component A, the monomer component B and the initiator to obtain a mixed solution, put the mixed solution into a funnel, and drop it into the heated solvent within 1.5 to 3 hours The copolymerization reaction obtains the fluorine-containing acrylate random copolymer. Additional initiators can be added two to three times as...

Embodiment 1

[0058] S1. Add 200g of xylene to a 500ml four-neck flask equipped with a mechanical stirrer, a condenser and a thermometer, raise the temperature to 105°C, and ventilate with nitrogen;

[0059] S2. Mix 125g of lauryl methacrylate, 125g of trifluorooctyl methacrylate and 2.5g of BPO evenly, drop them into the flask within 2h, and react for 1h. Then add 25g of xylene and 0.25g of BPO within 10min and keep warm for 1h. Then add 25g of xylene and 0.25g of BPO within 10min, and keep warm for 3h to obtain a colorless and transparent product. GPC test molecular weight, Mn=68000, PDI=2.1.

Embodiment 2

[0061] S1. Add 200 g of trimethylbenzene into a 500 ml four-necked flask equipped with mechanical stirring, a condenser, and a thermometer, raise the temperature to 105° C., and ventilate with nitrogen;

[0062] S2. Mix 125g of isooctyl methacrylate, 125g of trifluorooctyl methacrylate and 2g of BPO evenly, drop them into the flask within 2h, and react for 1h. Then add 25g of trimethylbenzene and 0.25g of BPO within 10min and keep warm for 1h. Then add 25g of trimethylbenzene and 0.25g of BPO within 10min, and keep warm for 3h to obtain a colorless and transparent product. GPC test molecular weight, Mn=71000, PDI=2.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com