Lithium-ion battery negative electrode slurry and lithium-ion battery

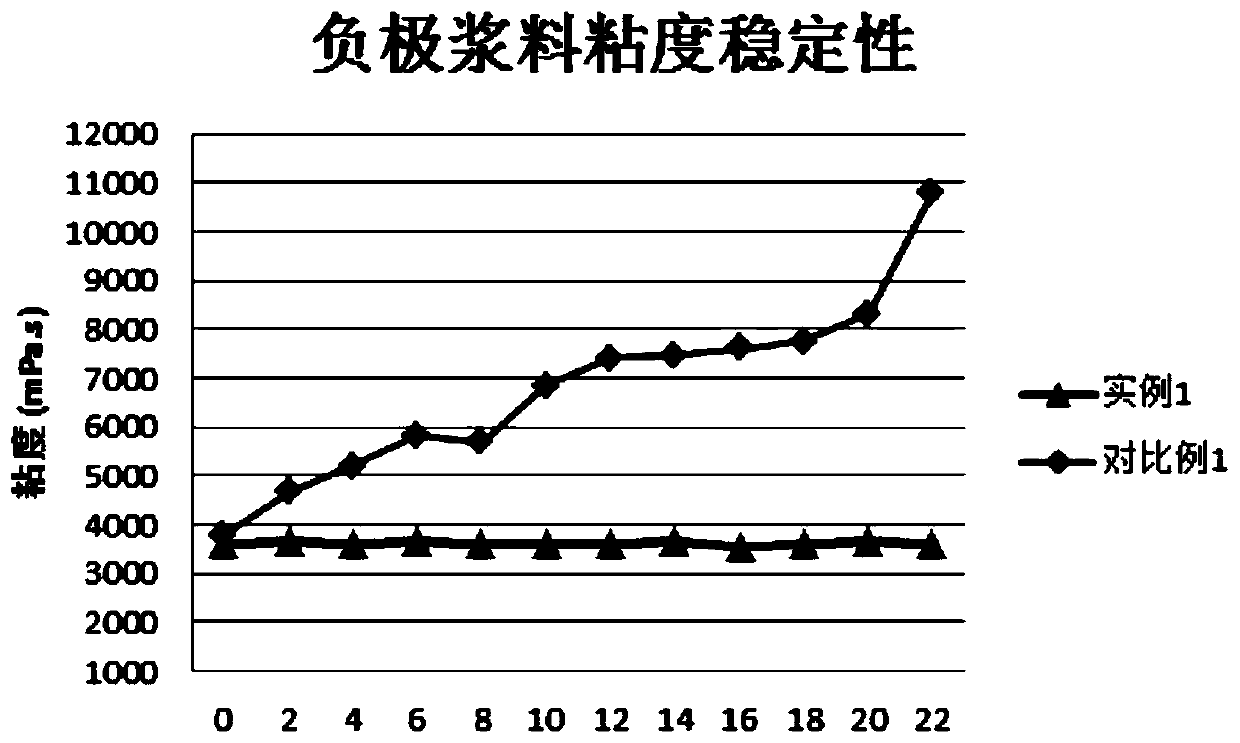

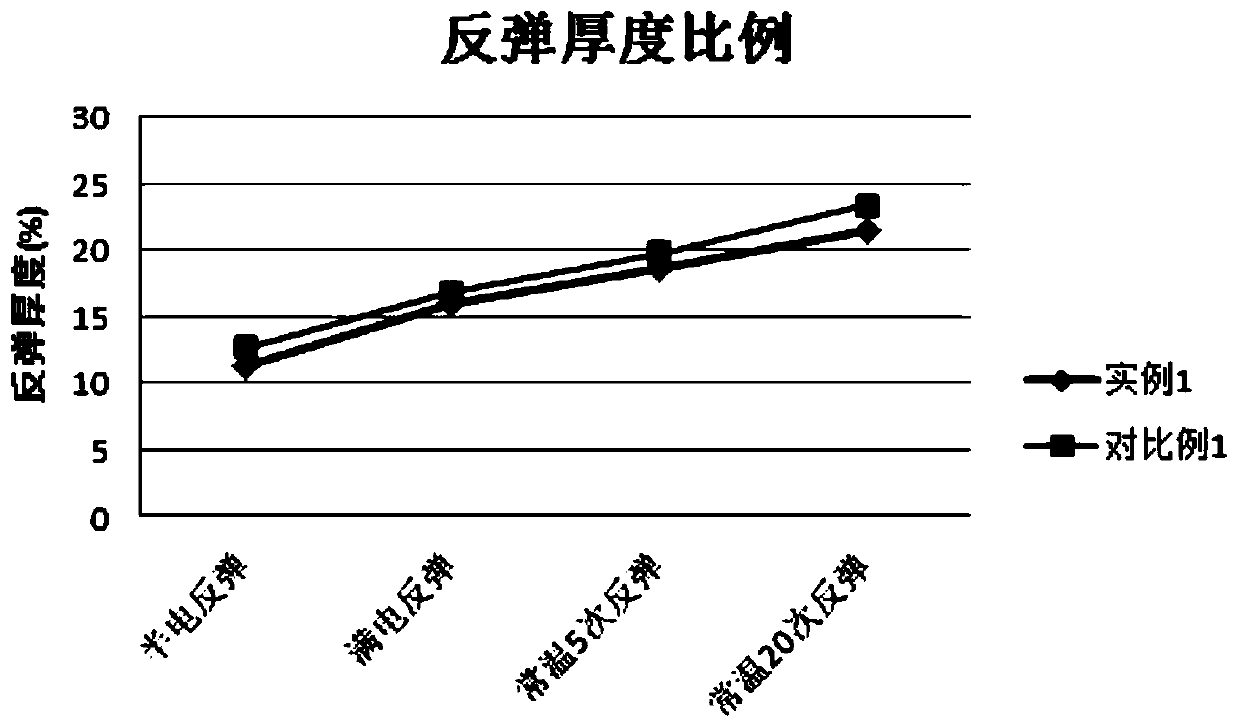

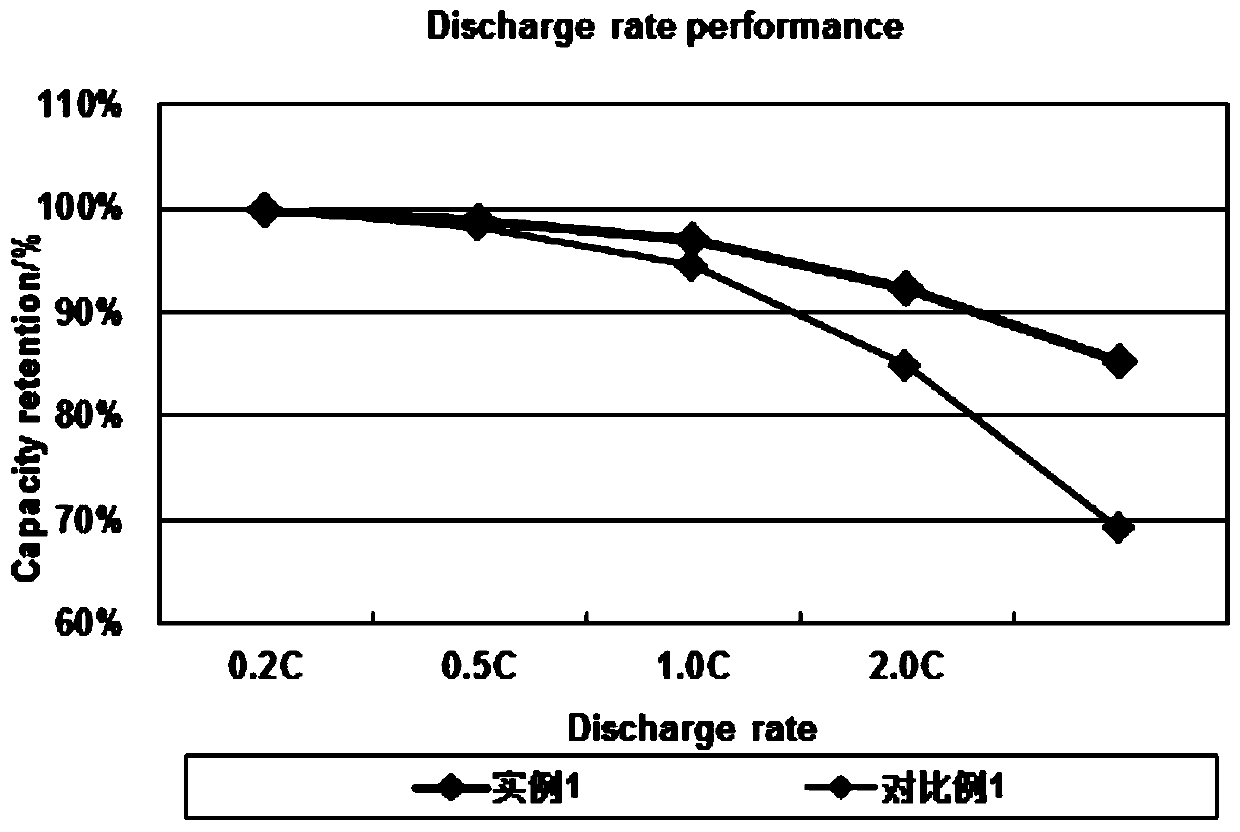

A lithium-ion battery, negative electrode slurry technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, circuits, etc., can solve problems such as abnormal coating and difficult batching, reduce slurry viscosity, improve contact interface, and reduce dispersion. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Prepare the negative electrode sheet: configure the negative electrode active material, conductive agent, thickener, binder, and silicone polymer into the negative electrode slurry in the following mass percentages: 97.8%: 0.5%: 0.5%: 1.0%: 0.2%, This ratio is the ratio of dry material mass, and the negative electrode active material of the present embodiment is artificial graphite, and conductive agent is conductive carbon black (Super P), and thickener is sodium carboxymethyl cellulose, and binding agent is water emulsion Styrene rubber (SBR), the silicone polymer is a methoxy polyether-modified silicone polymer containing a nitrile group;

[0044] Add deionized water and methoxy polyether-modified silicone polymer containing nitrile group to the double planetary mixer, add the ground conductive agent during the stirring process, and disperse for 20 minutes; first add 0.2% sodium carboxymethyl cellulose , stirred for 20 minutes; after mixing evenly, add graphite, thic...

Embodiment 2

[0056] The difference between this example and Example 1 is that the organosilicon polymer is a polyether-modified organosilicon polymer containing phenyl-terminated methoxy groups, and the ratio of the materials and the stirring process remain unchanged to prepare the negative electrode slurry; The negative electrode slurry is coated on the negative electrode current collector to prepare the negative electrode sheet. The positive electrode sheet and separator are the same as in Example 1.

[0057] The negative electrode sheet prepared in this example was processed by a roller press, and the compacted density of the active material layer was 1.73 g / cm 3 .

Embodiment 3

[0059] The difference between this example and Example 1 is that the silicone polymer is a modified silicone polymer containing epoxy-terminated methoxy polyether, and the ratio of materials and the stirring process remain unchanged to prepare the negative electrode slurry; The negative electrode slurry is coated on the negative electrode current collector to prepare the negative electrode sheet. The positive electrode sheet and separator are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com