Method for microwave rust removal and prevention

A technology of microwave and anti-rust agent, which is applied in the fields of anti-rust and metal rust removal, which can solve the problems of shortening the time of rust removal and anti-rust film formation, etc., and achieves the effects of easy automatic control, good biodegradability, and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Stack lightly rusted steel wires in parallel, and send them into the working tank filled with rust remover and antirust agent through the logistics conveyor. There are microwave generators on both sides of the working tank, and three microwave generators are placed on each side, the model is 2450±50MH2. Start the microwave generator to irradiate the steel wire with microwaves for 100 seconds, and then wash it with a neutralizing solution. The temperature of the neutralizing solution is 60°C and the pressure is 3Mpa.

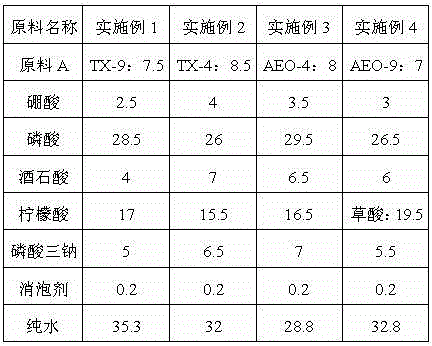

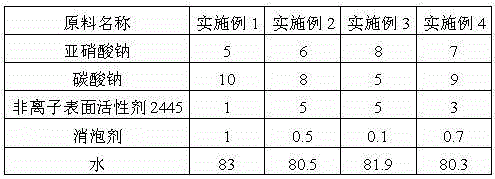

[0036] The preparation method of described rust remover and antirust agent is:

[0037] (1) Put boric acid, raw material A, phosphoric acid, and trisodium phosphate into the reaction kettle, and carry out the reaction under vacuum and constant stirring. The reaction temperature is 50°C, and the reaction time is 120 minutes;

[0038] (2) Turn off the vacuum, cool the temperature in the reactor to below 50°C, and then add it slowly into the reactor. Tartari...

Embodiment 2

[0042] Stack lightly rusted steel wires in parallel, and send them into the working tank filled with rust remover and antirust agent through the logistics conveyor. There are microwave generators on both sides of the working tank, and three microwave generators are placed on each side, the model is 2450±50MH2. Start the microwave generator to irradiate the steel wire with microwave for 160 seconds, and then wash it with a neutralizing solution. The temperature of the neutralizing solution is 80°C and the pressure is 4 Mpa.

[0043] The preparation method of described rust remover and antirust agent is:

[0044] (1) Put boric acid, raw material A, phosphoric acid, and trisodium phosphate into the reaction kettle, and carry out the reaction under vacuum and constant stirring. The reaction temperature is 60°C, and the reaction time is 100 minutes;

[0045] (2) Turn off the vacuum, cool the temperature in the reactor to below 50°C, and then add it slowly into the reactor. Tartaric ...

Embodiment 3

[0049] Stack the steel wires that are heavily rusted and have formed an oxide layer on the surface in parallel, and send them into the working tank filled with rust and rust inhibitors through the logistics conveyor. There are microwave generators on both sides of the working tank, and three microwave generators are placed on each side. The model is 2450±50MH2. Start the microwave generator to irradiate the steel wire with microwaves for 200 seconds, and then wash it with a neutralizing solution. The temperature of the neutralizing solution is 60°C and the pressure is 3 Mpa.

[0050] The preparation method of described rust remover and antirust agent is:

[0051] (1) Put boric acid, raw material A, phosphoric acid, and trisodium phosphate into the reaction kettle, and carry out the reaction under vacuum and constant stirring. The reaction temperature is 70°C, and the reaction time is 80 minutes;

[0052] (2) Turn off the vacuum, cool the temperature in the reactor to below 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com