Anti-carbon monoxide composite anode electrode catalyst layer structure and preparation method

A technology of electrode catalytic layer and composite anode, which is applied in the direction of battery electrodes, structural parts, circuits, etc., can solve the problems of low utilization efficiency of electrocatalysts, low anti-CO poisoning ability, slow proton migration speed, etc., and achieve fast proton migration speed, Improve utilization rate and strong anti-CO poisoning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

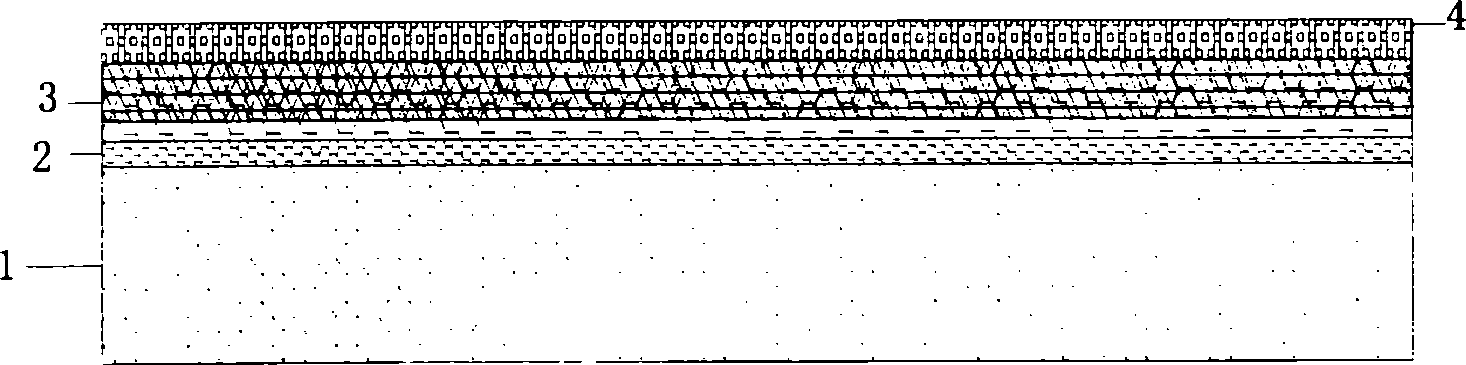

[0046] Such as figure 1 As shown, the anti-CO composite catalytic layer for proton exchange membrane fuel cells of the present invention uses Pt and / or Ru or Au as active components, and its structure is composed of three or more catalytic layers with different functions. The hydrophobic CO primary oxidation layer composed of water agent is the outer catalytic layer, and the hydrophilic electrochemical reaction catalytic layer composed of electrocatalyst and proton conductor is the inner catalytic layer. The partially hydrophobic and partially hydrophilic CO secondary oxidation layer with proton conductor components is the intermediate catalytic layer; the outer catalytic layer is supported by the gas diffusion layer, and the intermediate catalytic layer is located between the outer catalytic layer and the inner catalytic layer. The conductor portion is in contact with the inner catalytic layer, and the other side of the inner catalytic layer is in contact with the proton exch...

Embodiment 2

[0059] 1) Preparation of the outer catalytic layer: use a primary balance to weigh 42.6 mg of 30% Pt / C electrocatalyst, add a small amount of deionized water to completely wet the electrocatalyst, then add 210 mg of XC-72 carbon powder, and then follow (electrocatalyst + carbon powder) 50 times the weight of absolute ethanol and ethylene glycol (25 times each of the two dispersants), ultrasonically oscillating at a frequency of 40KHz for 30 minutes until completely mixed evenly, according to (outer catalytic layer + microporous layer ) 50% of the total weight by adding 10% PTFE emulsion, and continuing to ultrasonically oscillate at a frequency of 40KHz for 30min until uniform to form a slurry. After the prepared slurry was subjected to gel treatment in a constant temperature water margin of 90°C, the slurry was evenly coated on SGL carbon paper using a plastic scraper to obtain an intermediate product; then the prepared above (microporous Layer (MPL)+catalytic layer) intermed...

Embodiment 3

[0065] 1) Preparation of the outer catalytic layer: according to the Ru loading of 0.15mg / cm 2 , (electrocatalyst + carbon powder): dispersant = 1: 40 and (electrocatalyst + carbon powder): PTFE = 7: 3 ratio, using 30% Ru / C electrocatalyst, XC-72 carbon powder, absolute ethanol And three kinds of raw materials of PTFE micropowder, prepare slurry according to the method for step 1) among the embodiment 2. After the prepared slurry was subjected to gel treatment in a constant temperature water margin at 90°C, the slurry was evenly coated on SGL carbon paper using Doctor Blade, and then the prepared above (microporous layer (MPL)+catalytic Layer) is put into roasting furnace, according to step 2) method in embodiment 1, roasting is made to be the outer catalytic layer of substrate with gas diffusion layer;

[0066]2) Prepare the intermediate catalyst layer with the outer catalyst layer as the substrate: according to the ratio of electrocatalyst: dispersant = 1: 30 and electrocat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com