Multistage micropore composite electrode material and manufacturing method thereof

A composite electrode and porous material technology, which is applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problems of low energy density, small specific surface area, low conductivity, etc., and achieve high energy storage density, high ratio The effect of surface area and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

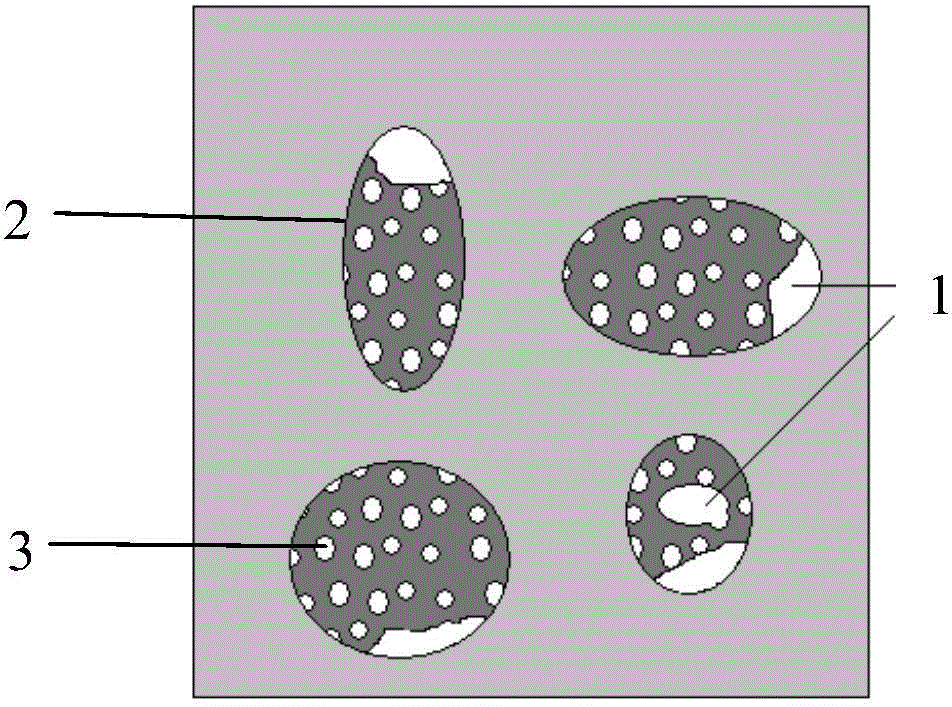

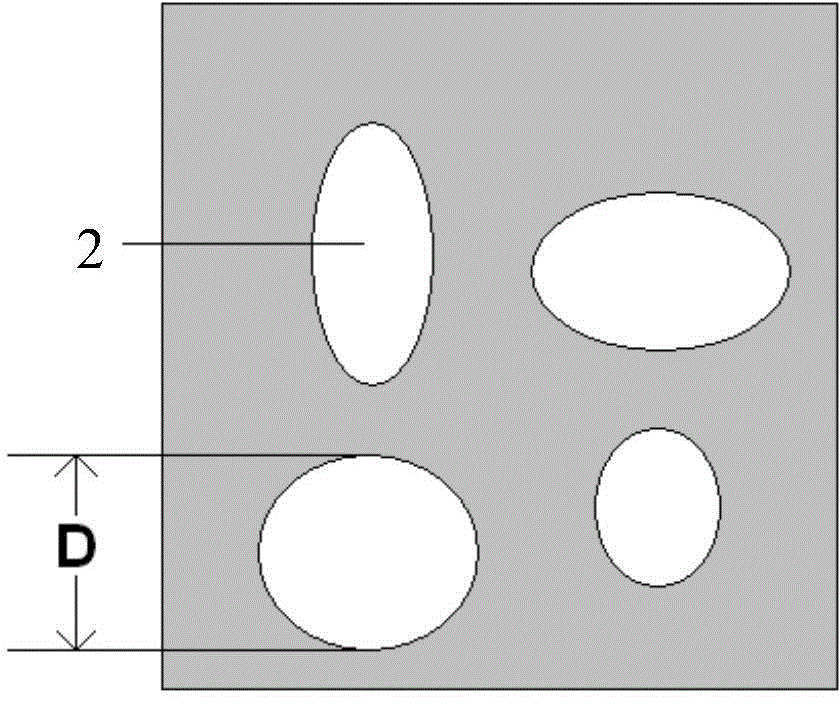

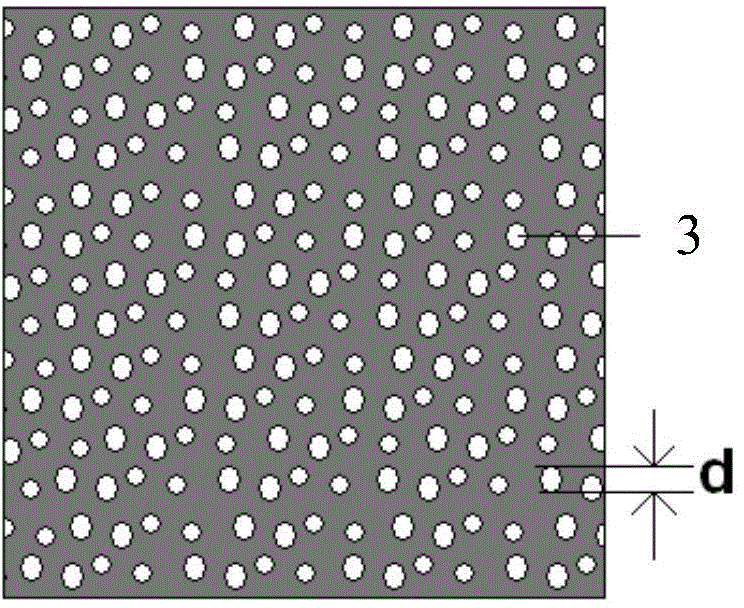

[0030] A multi-level microporous composite electrode material with a three-dimensional pore structure, characterized in that: a small-pore material with a three-dimensional network structure and a large-pore material with a three-dimensional network structure are covered with each other, and the small-pore material is filled in the large In the pores of the porous material, there are unfilled gaps in the pores of the macroporous material; the macroporous material is nickel foam, and the average pore diameter is 20 mm; the small porosity material is a mixed colloid of organic colloids and nanowires cured and corroded The resulting porous material has an average pore diameter of 1 nanometer.

[0031] The preparation method of a kind of multi-level microporous composite electrode material described in this embodiment can be prepared in the following manner:

[0032] Mix organic colloids and nanowires to obtain mixed colloids, then soak nickel foam macroporous materials in the mix...

Embodiment 2

[0034] A multi-level microporous composite electrode material with a three-dimensional pore structure, characterized in that: a small-pore material with a three-dimensional network structure and a large-pore material with a three-dimensional network structure are covered with each other, and the small-pore material is filled in the large In the pores of the porous material, there are unfilled gaps in the pores of the macroporous material; the macroporous material is aluminum foam, and the average pore diameter is 0.1 mm; the small porosity material is conductive hydrogel (polyaniline), The average pore diameter is 100 microns.

[0035] The preparation method of a kind of multi-level microporous composite electrode material described in this embodiment can be prepared in the following manner:

[0036] The macroporous material, aluminum foam, is soaked in a conductive hydrogel (polyaniline) solution, so that the hydrogel solution fills the macropores; the hydrogel is subsequentl...

Embodiment 3

[0038] A multi-level microporous composite electrode material with a three-dimensional pore structure, characterized in that: a small-pore material with a three-dimensional network structure and a large-pore material with a three-dimensional network structure are covered with each other, and the small-pore material is filled in the large In the pores of the porous material, there is an unfilled gap in the pores of the macroporous material; the macroporous material is aluminum foam, and the average pore diameter is 10 mm; the small void material is a monomer (aniline) of a hydrogel , with an average pore diameter of 1 micron.

[0039] The preparation method of a kind of multi-level microporous composite electrode material described in this embodiment can be prepared in the following manner:

[0040] Aluminum foam, a macroporous material, is soaked in a hydrogel monomer (aniline) solution, so that the hydrogel monomer solution fills the macropores; then a cross-linking agent is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Average pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com