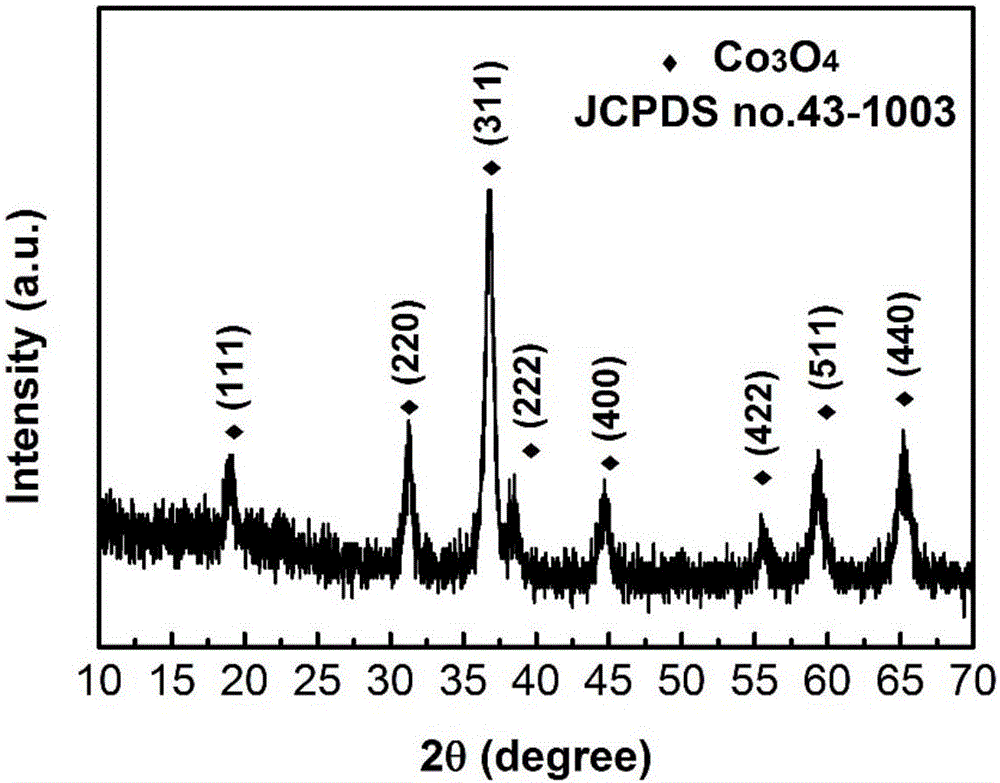

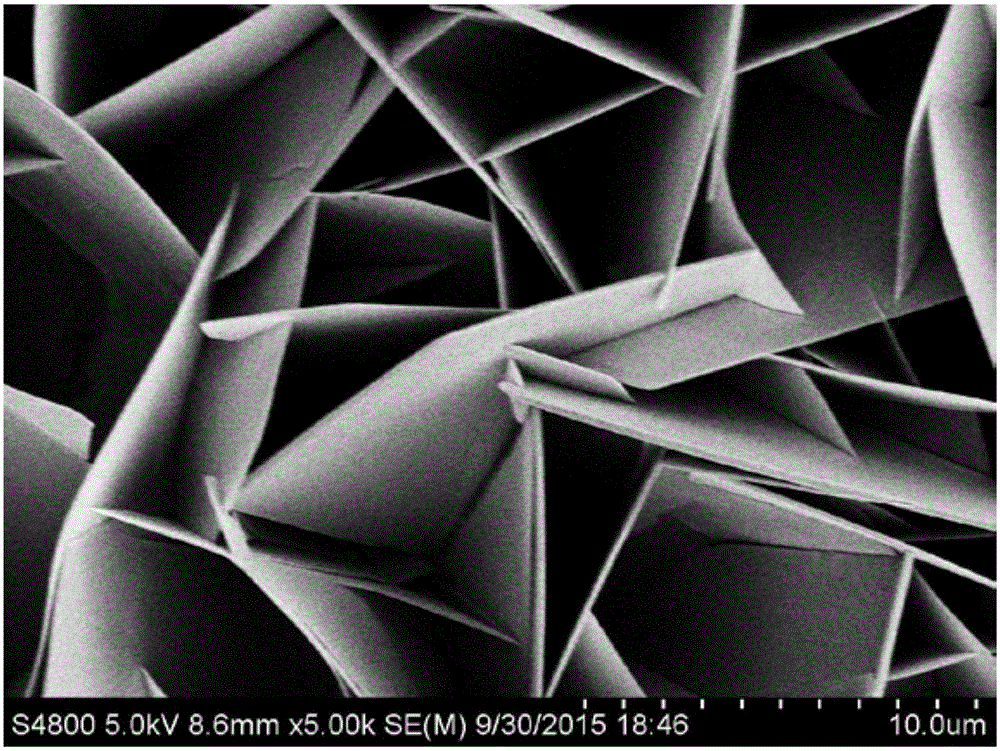

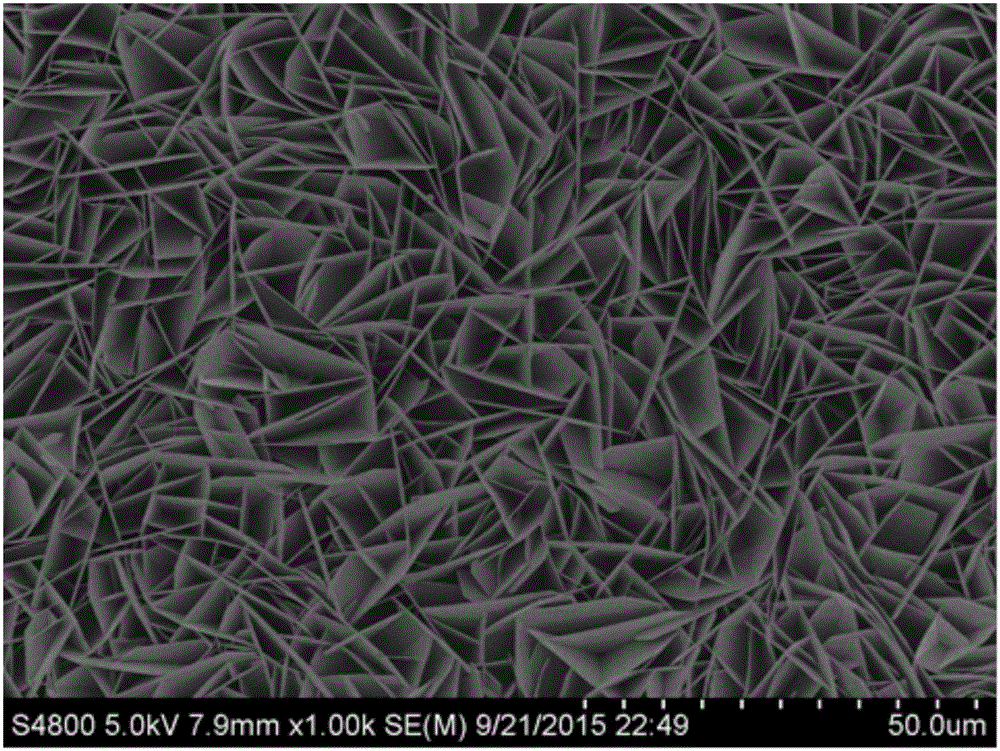

Cross cobalto-cobaltic oxide nanosheet array, gas sensor containing the array and application thereof

A technology of cobalt tetroxide nanometer and nanosheet array, applied in the field of sensors, can solve problems such as poor sensitivity, and achieve the effects of reducing reaction steps, lowering working temperature, and improving detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] The fabrication method of crossed cobalt trioxide nanosheet array of the present invention comprises the following steps:

[0072] 1) Mix and stir cobalt nitrate, urea, ammonium fluoride, trisodium citrate dihydrate and deionized water with a molar ratio of 10:5:5:1 at room temperature;

[0073] 2) the uniform solution obtained is moved into a stainless steel autoclave with a polytetrafluoroethylene lining, and the filling degree of the autoclave is 80%;

[0074] 3) Put the cleaned and electrode-plated insulating substrate in the solution, control the hydrothermal reaction temperature to 95°C, and the reaction time is 12 hours. The insulating substrate can be an insulating ceramic sheet, silicon sheet or glass Substrate;

[0075] 4) After the reaction is completed, the substrate is taken out and rinsed and dried with deionized water and ethanol respectively to obtain a precursor of tricobalt tetroxide;

[0076] 5) The obtained cobalt tetroxide precursor is heat-treate...

Embodiment 2

[0087] Comparative Example 2 (see RSC Advances, 2015, 5, 59976)

[0088] The manufacture method of tricobalt tetraoxide nanosheet, comprises the following steps:

[0089] 1) Dissolve 0.02mmol polyethylene glycol-polypropylene glycol-polyethylene glycol copolymer (ethylene glycol)-block-poly(propylene glycol)-block-poly(ethylene glycol)) in 16.5mL ethanol and 1mL deionized water Stir to obtain a homogeneous solution;

[0090] 2) 0.5mmol of hexamethylenetetramine, 0.5mml of cobalt acetate and 13mL of ethylene glycol were dissolved in the solution obtained in step 1) and stirred evenly;

[0091] 3) The homogeneous solution obtained in step 2) was left to stand for 12 hours;

[0092] 4) Move the obtained homogeneous solution into a stainless steel autoclave lined with polytetrafluoroethylene, control the hydrothermal reaction temperature to 170°C, and the reaction time to be 2 hours;

[0093] 5) After the reaction is completed, the obtained turbid solution is centrifuged to obt...

Embodiment 3

[0122] The fabrication method of crossed cobalt trioxide nanosheet array of the present invention comprises the following steps:

[0123] 1) Mix and stir cobalt chloride, urea, ammonium fluoride, trisodium citrate dihydrate and deionized water with a molar ratio of 5:3:2:1 at normal temperature;

[0124] 2) the uniform solution obtained is moved into a stainless steel autoclave with a polytetrafluoroethylene lining, and the filling degree of the autoclave is 60%;

[0125] 3) Put the cleaned and electrode-plated insulating substrate in the solution, control the hydrothermal reaction temperature to 110°C, and the reaction time is 13 hours. The insulating substrate can be an insulating ceramic sheet, silicon sheet or glass Substrate;

[0126] 4) After the reaction is completed, the substrate is taken out and rinsed and dried with deionized water and ethanol respectively to obtain a precursor of tricobalt tetroxide;

[0127] 5) The obtained cobalt tetroxide precursor is heat-tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com