Semiconductor structure, formation method of semiconductor structure, complementary metal-oxide-semiconductor transistor (CMOS) and formation method of CMOS

A semiconductor and stress technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, transistors, etc., to reduce leakage current, improve electrical performance, and improve leakage current phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] It can be seen from the background technology that the existing fin field effect transistor has a serious leakage current phenomenon. In this regard, the inventors of the present invention have studied the fin field effect transistor forming process and found that the fin field effect transistor of the prior art The fin formation process of the transistor is:

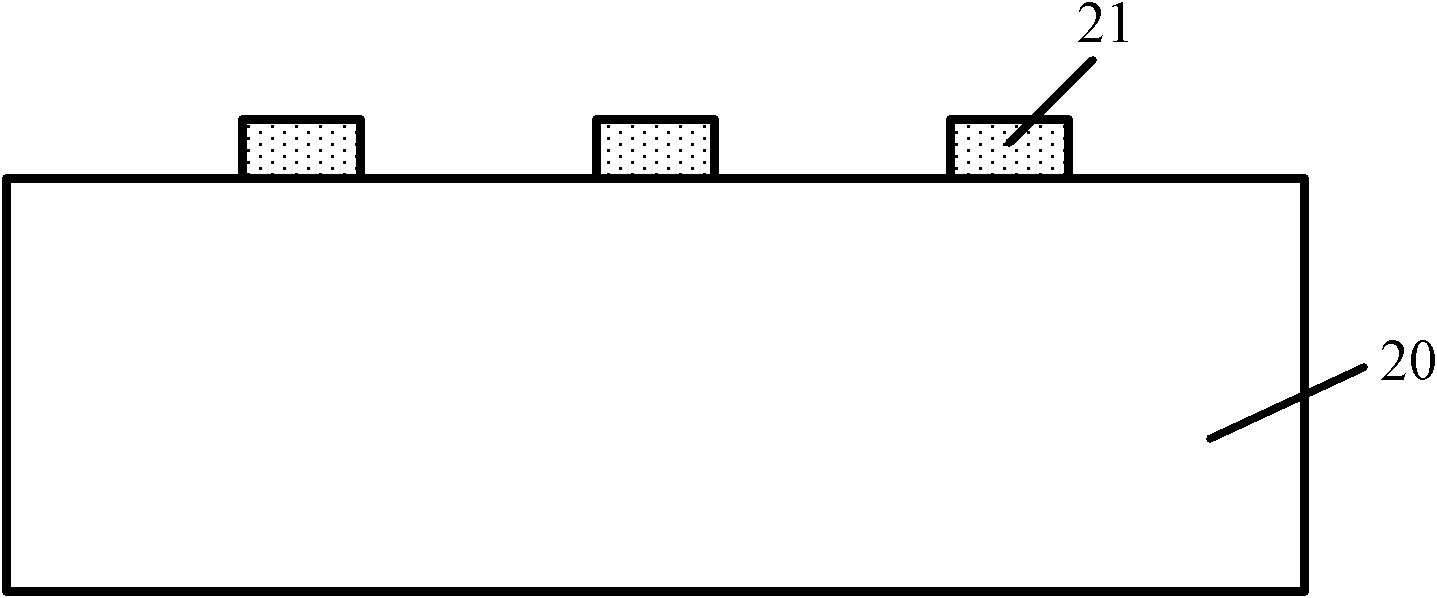

[0060] Please refer to figure 2 , a substrate 20 is provided, and a patterned photoresist layer 21 is formed on the surface of the substrate 20 .

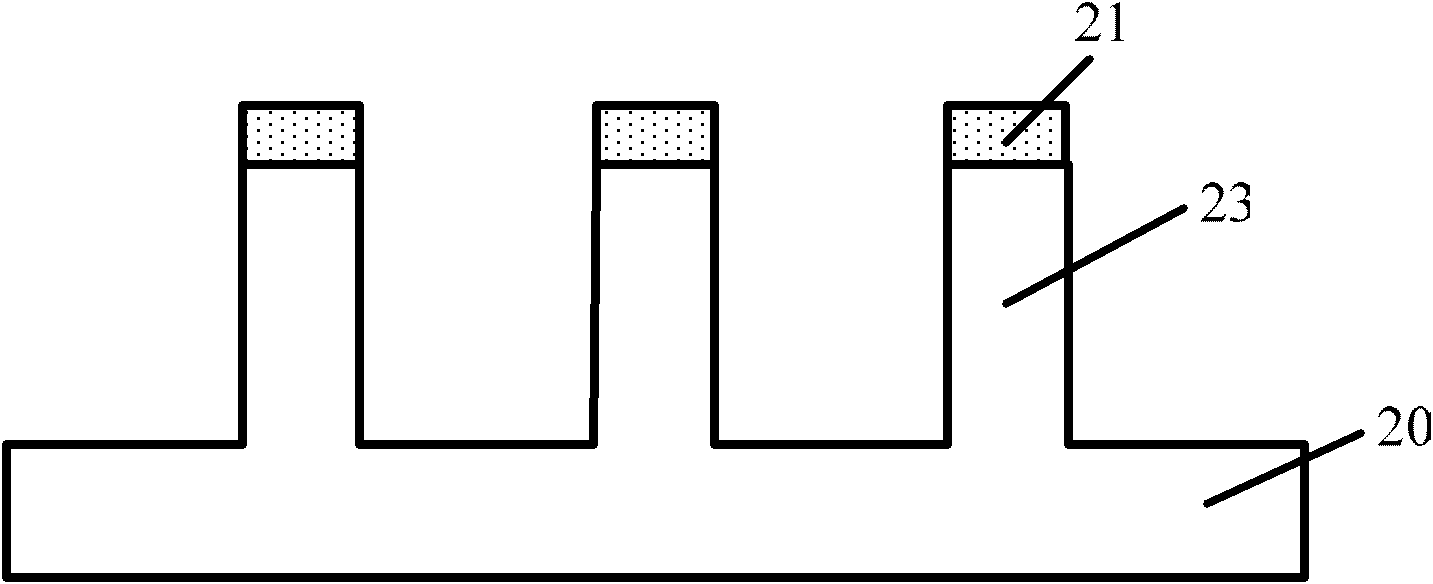

[0061] Please refer to image 3 , using the patterned photoresist layer 21 as a mask to etch the base 20 to form protruding fins 23 .

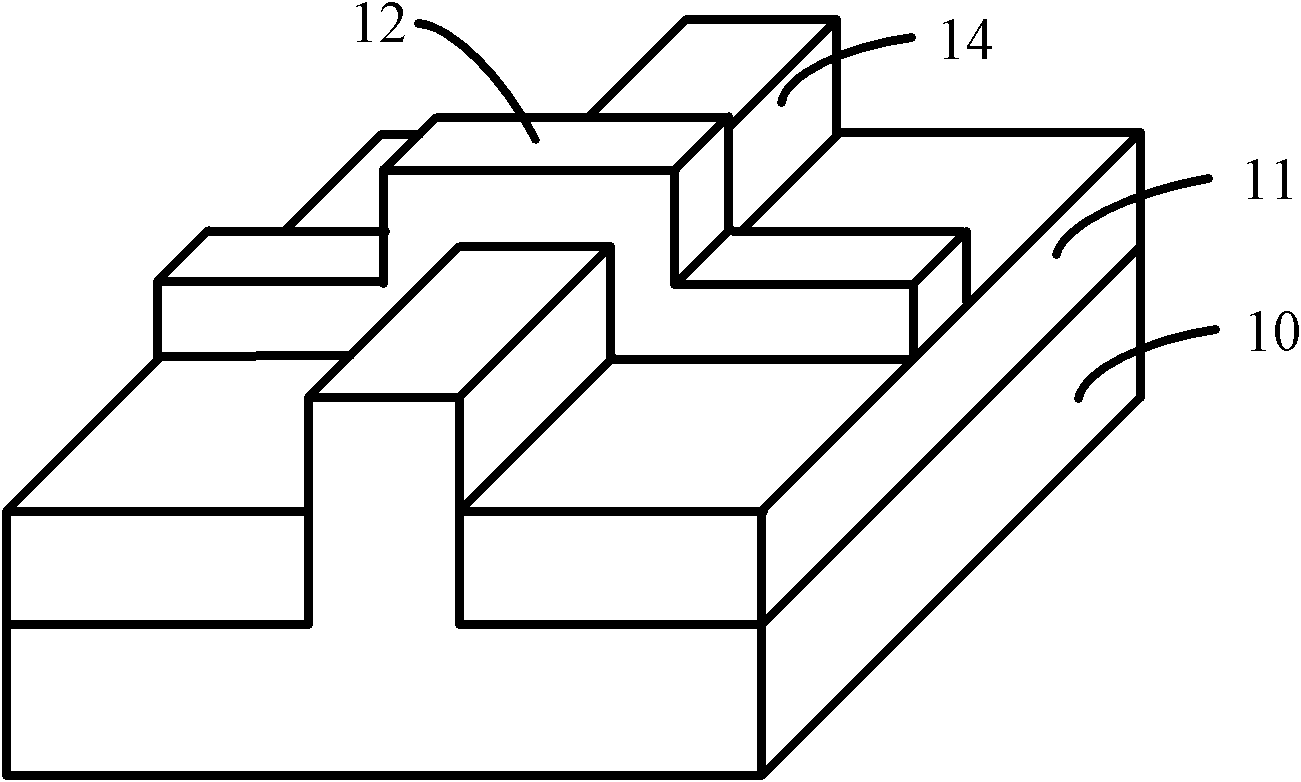

[0062] Afterwards, the inventors of the present invention formed fin field effect transistors using the fins formed by the above forming process (please refer to figure 1 ), and researched the leakage current phenomenon of fin field effect transistors, it was found that: the fins of the existing fin field effect transistors are ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Stress | aaaaa | aaaaa |

| Stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com