Antibacterial multilayer composite hollow fiber membrane material and preparation method thereof

A multi-layer composite, fiber membrane technology, applied in hollow filament manufacturing, fiber processing, fiber chemical characteristics, etc., can solve problems such as easy agglomeration, limited application, etc., to improve dispersibility, reduce migration speed, and improve thermal stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

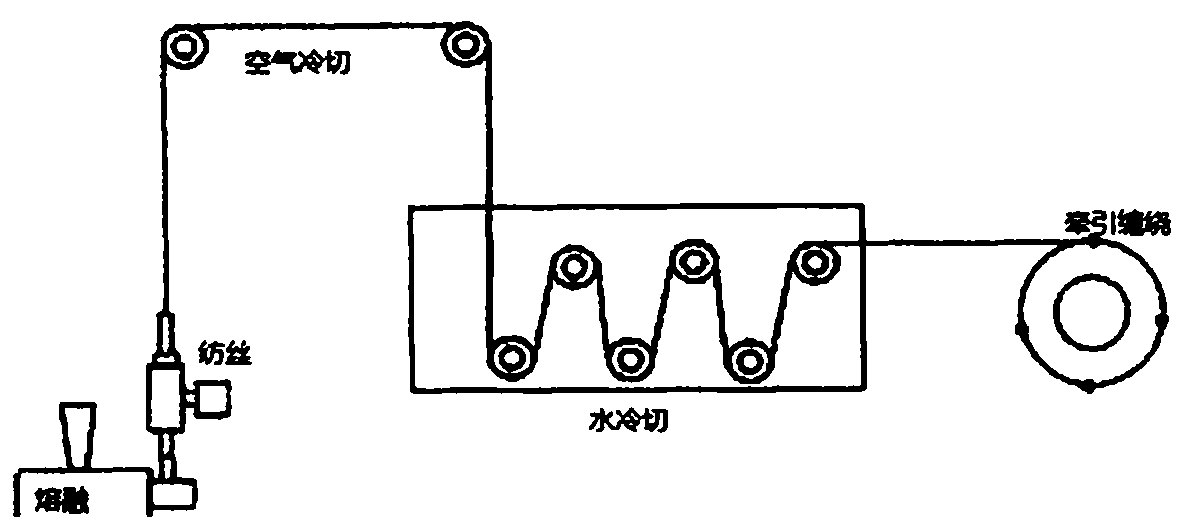

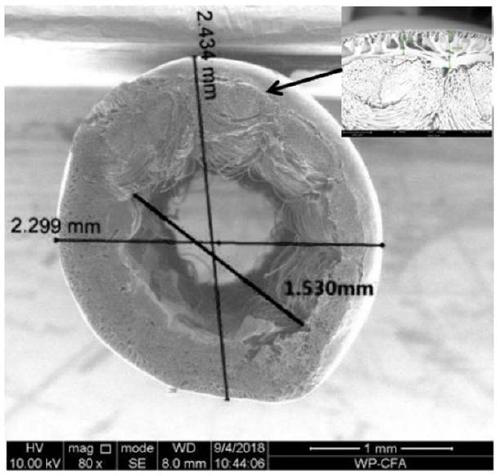

Method used

Image

Examples

Embodiment 1

[0050] An antibacterial multilayer composite hollow fiber membrane material consists of the following raw materials in parts by weight:

[0051] PP resin: 30 parts

[0052] PVB resin: 5 parts

[0053] PVDF resin: 5 parts

[0054] Compatibilizer: 3 parts

[0055] Antimicrobial: 1 part

[0056] Lubricant: 0.5 parts

[0057] Antioxidant: 0.1 parts.

[0058] The antibacterial agent is modified graphene / chitosan intercalated zirconium phosphate.

[0059] The modified graphene / chitosan intercalated zirconium phosphate antibacterial agent is prepared by the following method:

[0060] (1) Preparation of modified graphene

[0061] Graphene oxide was prepared by the improved Hummers method, and 5 g of graphene oxide was weighed, added to a three-necked flask filled with 100 mL of acetone, and 0.1 g of silane coupling agent was added while stirring, reacted at 50 ° C for 1 h, and suction filtered. Dry to obtain modified graphene.

[0062] (2) Preparation of modified graphene / chito...

Embodiment 2

[0077] An antibacterial multilayer composite hollow fiber membrane material consists of the following raw materials in parts by weight:

[0078] PP resin: 35 parts

[0079] PVB resin: 6.5 parts

[0080] PVDF resin: 7 parts

[0081] Compatibilizer: 4.5 parts

[0082] Antimicrobial: 2 parts

[0083] Lubricant: 0.9 parts

[0084] Antioxidant: 0.2 parts.

[0085] The antibacterial agent is modified graphene / chitosan intercalated zirconium phosphate.

[0086] The modified graphene / chitosan intercalated zirconium phosphate antibacterial agent is prepared by the following method:

[0087] (1) Preparation of modified graphene

[0088] Graphene oxide was prepared by the improved Hummers method, and 7 g of graphene oxide was weighed, added to a three-necked flask filled with 100 mL of acetone, and 0.35 g of aluminate coupling agent was added while stirring, and reacted at a temperature of 55 ° C for 1.5 h. Suction filtration, drying to obtain modified graphene.

[0089] (2) Pre...

Embodiment 3

[0103] An antibacterial multilayer composite hollow fiber membrane material consists of the following raw materials in parts by weight:

[0104] PP resin: 40 parts

[0105] PVB resin: 7.5 parts

[0106] PVDF resin: 7 parts

[0107] Compatibilizer: 6 parts

[0108] Antimicrobial: 3 parts

[0109] Lubricant: 2.3 parts

[0110] Antioxidant: 0.38 parts.

[0111] The antibacterial agent is modified graphene / chitosan intercalated zirconium phosphate.

[0112] The modified graphene / chitosan intercalated zirconium phosphate antibacterial agent is prepared by the following method:

[0113] (1) Preparation of modified graphene

[0114] Graphene oxide was prepared by the improved Hummers method. Weighed 7g of graphene oxide and put it into a three-necked flask filled with 100mL of acetone, and added 0.4g of titanate coupling agent while stirring, reacted at 60°C for 2h, pumped Filter and dry to obtain modified graphene.

[0115] (2) Preparation of modified graphene / chitosan

[01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com