Preparation method of montmorillonite-modified soil remediation agent

A soil remediation agent and montmorillonite technology, which is applied in the field of soil remediation, can solve the problems of reducing the migration speed of heavy metal elements, and achieve the effects of solving the problem of heavy metal pollution, improving the market promotion and application value, and reducing the migration speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

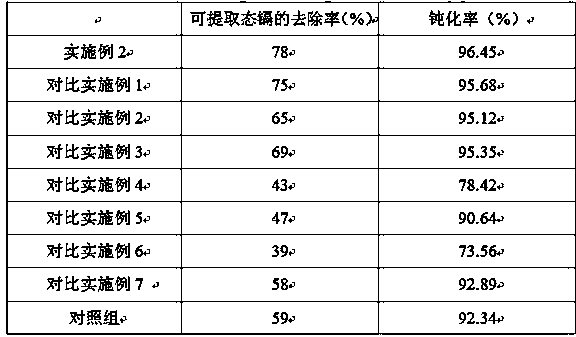

Examples

Embodiment 1

[0039] A preparation method of montmorillonite modified material soil remediation agent, comprising the steps of:

[0040] (1) Preparation of modified montmorillonite:

[0041] a. The montmorillonite is placed in a numerically controlled continuous steam explosion machine for continuous steam explosion treatment, and the total time of steam explosion treatment is 30s;

[0042] b. First immerse the steam explosion product obtained in operation a in biochemical fulvic acid with a mass fraction of 5% for 30 minutes, then filter it out, rinse it with deionized water, and dry it for later use;

[0043] c. Put sodium dodecylbenzenesulfonate and sodium glycocholate into the mixing tank at a weight ratio of 2:2.3, heat to keep the temperature in the mixing tank at 70°C, and stir for 20 minutes to obtain modified liquid A for later use ;

[0044] d. First put 50% glycerin and 75% ethanol into the reaction kettle at a volume ratio of 3:5, stir and mix well, then raise the temperature ...

Embodiment 2

[0066] A preparation method of montmorillonite modified material soil remediation agent, comprising the steps of:

[0067] (1) Preparation of modified montmorillonite:

[0068] a. The montmorillonite is placed in a numerically controlled continuous steam explosion machine for continuous steam explosion treatment, and the total time of steam explosion treatment is 35s;

[0069] b. First immerse the steam explosion product obtained in operation a in biochemical fulvic acid with a mass fraction of 6% for 35 minutes, then filter it out, rinse it with deionized water, and dry it for later use;

[0070] c. Put sodium dodecylbenzenesulfonate and sodium glycocholate into the stirring tank at a weight ratio of 2.5:2.5, heat to keep the temperature in the stirring tank at 75°C, and stir for 25 minutes to obtain modified liquid A for later use ;

[0071] d. First put 50% glycerin and 75% ethanol into the reaction kettle at a volume ratio of 3.5:5.5, stir and mix well, then raise the te...

Embodiment 3

[0093] A preparation method of montmorillonite modified material soil remediation agent, comprising the steps of:

[0094] (1) Preparation of modified montmorillonite:

[0095] a. The montmorillonite is placed in a numerically controlled continuous steam explosion machine for continuous steam explosion treatment, and the total time of steam explosion treatment is 40s;

[0096] b. First immerse the steam explosion product obtained in operation a into biochemical fulvic acid with a mass fraction of 7% for 40 minutes, then filter it out, rinse it with deionized water, and dry it for later use;

[0097] c. Put sodium dodecylbenzenesulfonate and sodium glycocholate into the mixing tank at a weight ratio of 3:2.7, heat to keep the temperature in the mixing tank at 80°C, and stir for 30 minutes to obtain modified liquid A for later use ;

[0098]d. First put 50% glycerin and 75% ethanol into the reaction kettle at a volume ratio of 4:6, stir and mix well, then raise the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com