Antistatic reinforced polypropylene plastic packing barrel

A technology for polypropylene plastic and packaging drums, which is applied in the field of antistatic enhanced polypropylene plastic packaging drums, which can solve the problems of shortening the service life of plastic packaging drums, short duration of antistatic effect, and lower concentration, and achieve good UV shielding effect, Excellent antistatic effect, aging resistance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

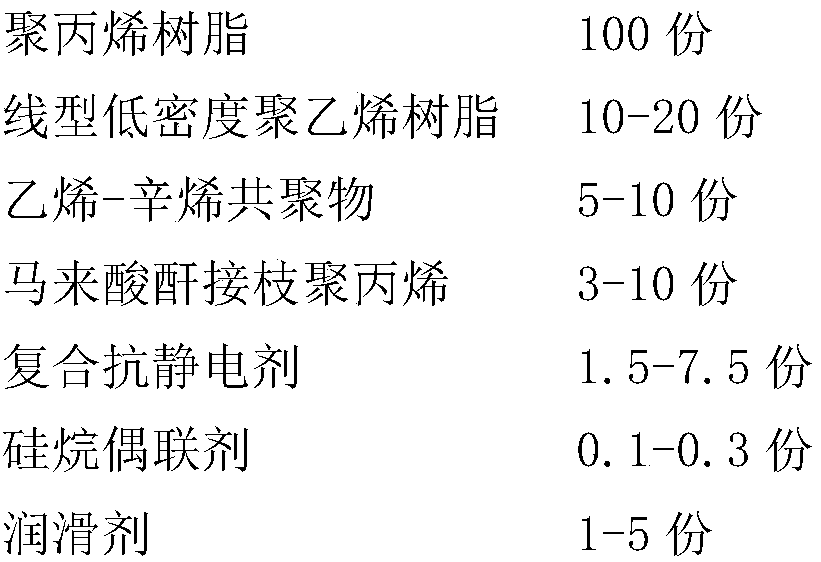

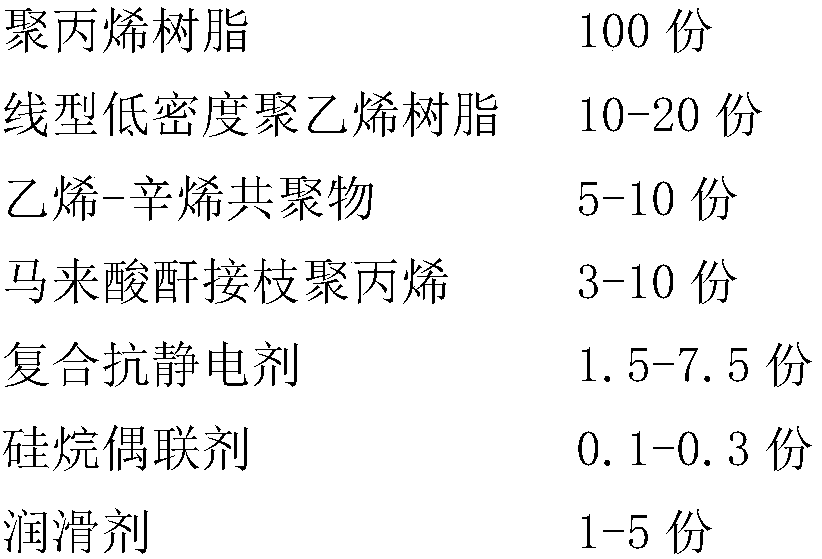

[0023] An antistatic enhanced polypropylene plastic packaging bucket is made of the following components in parts by weight:

[0024] 100 parts of polypropylene resin, 10 parts of linear low density polyethylene resin, 5 parts of ethylene-octene copolymer, 3 parts of maleic anhydride grafted polypropylene, 1.5 parts of composite antistatic agent, silane coupling agent KH-550 0.1 1 part, polyethylene wax 1 part.

[0025] Wherein, the composite antistatic agent is made of the following components in parts by weight:

[0026] 2 parts of conductive mesoporous nano titanium dioxide and 1 part of glycerol monostearate antistatic agent.

[0027] The preparation method of the composite antistatic agent comprises the following steps: dissolving the glycerol monostearate antistatic agent in absolute ethanol, controlling its concentration to be 2.5%, adding conductive mesoporous nano-titanium dioxide to the above solution, and ultrasonically dispersing 15 minutes, stirred for 4 hours, ...

Embodiment 2

[0030] An antistatic enhanced polypropylene plastic packaging bucket is made of the following components in parts by weight:

[0031] 100 parts of polypropylene resin, 20 parts of linear low density polyethylene resin, 10 parts of ethylene-octene copolymer, 10 parts of maleic anhydride grafted polypropylene, 7.5 parts of composite antistatic agent, 0.3 parts of silane coupling agent KH-560 5 parts, polyethylene wax.

[0032] Wherein, the composite antistatic agent is made of the following components in parts by weight:

[0033] 10 parts of conductive mesoporous nano titanium dioxide and 10 parts of alkyl phosphate diethanolammonium salt antistatic agent.

[0034] The preparation method of the composite antistatic agent comprises the following steps: dissolving the alkyl phosphate diethanolammonium salt antistatic agent in absolute ethanol, controlling its concentration to be 5%, adding conductive mesoporous nano-titanium dioxide to the above solution, and ultrasonically dispe...

Embodiment 3

[0037] An antistatic enhanced polypropylene plastic packaging bucket is made of the following components in parts by weight:

[0038] 100 parts of polypropylene resin, 15 parts of linear low density polyethylene resin, 8 parts of ethylene-octene copolymer, 7 parts of maleic anhydride grafted polypropylene, 4 parts of composite antistatic agent, silane coupling agent KH-570 0.2 3 parts, polypropylene wax 3 parts.

[0039] Wherein, the composite antistatic agent is made of the following components in parts by weight:

[0040] 6 parts of conductive mesoporous nano-titanium dioxide and 5 parts of ethoxyalkylamine antistatic agent.

[0041] The preparation method of the composite antistatic agent comprises the following steps: dissolving the ethoxyalkylamine antistatic agent in absolute ethanol, controlling its concentration to be 4%, adding conductive mesoporous nano-titanium dioxide to the above solution, ultrasonically dispersing for 60 minutes, Stir for 24 hours, filter, wash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com