Frozen pre-deep-fried fish and shrimp type powder-coating food and preparation method thereof

A technology of pre-frying, fish and shrimp, which is applied in the direction of food ingredients, food coating, yeast-containing food ingredients, etc., can solve the problems of oil consumption, time loss, poor taste, easy "soaking", etc., and achieve simplified frying, The effect of good looks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

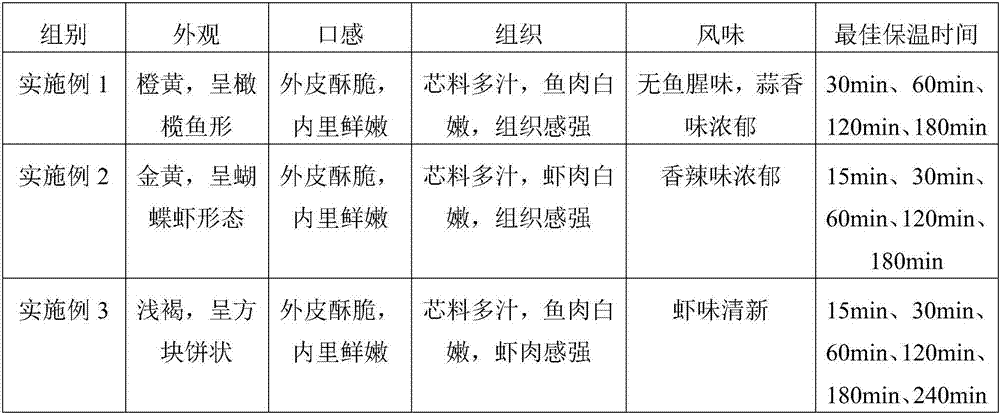

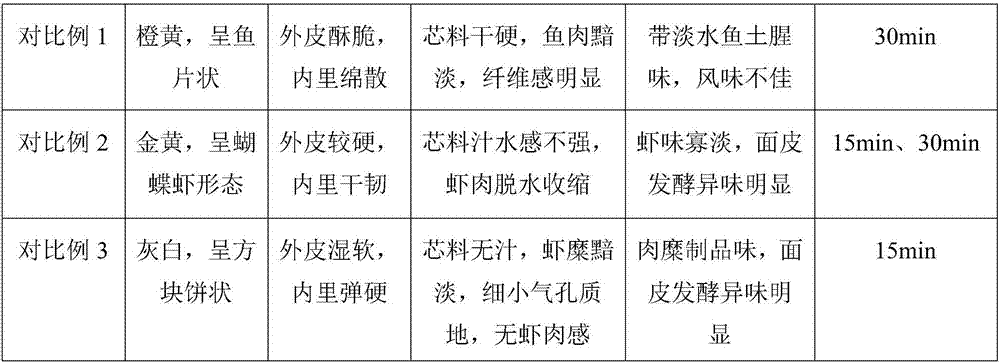

Examples

Embodiment 1

[0041] A frozen pre-fried fish and shrimp bread-coated food, the core material (based on 100% of the total mass) consists of 82-86% of tilapia belly meat with reverse slices, 1-2% of compound phosphate, 1 ~2% guar gum, 1.5~3% corn starch, 8~10% ice water, 0.8~1.5% cooking wine, 1~1.5% marinade (containing salt, white sugar, chicken powder, garlic essence powder, spicy marinade), in the preferred version, the core material is made of 85% tilapia belly meat, 1% complex phosphate, 1% guar gum, 2% corn starch, 9% made of ice water, 1% cooking wine, and 1% marinade.

[0042] In this embodiment, the belly meat of tilapia is taken as an example, and the complete meat pieces of other fishes can also be processed in the same way.

[0043] Prepare as follows:

[0044] 1. Stir and disperse the compound phosphate, guar gum, corn starch, and marinade, then add cooking wine and ice water for beating, first stir at a low speed of 120r / min for 1min, then stir at a medium speed of 720r / min f...

Embodiment 2

[0055] A frozen pre-fried fish and shrimp bread-coated food, the core material (based on 100% of the total mass) consists of 82-86% butterfly shrimp (51-60 tails / lb), 1-2% compound phosphate, 1-2% guar gum, 1.5-3% corn starch, 8-10% ice water, 0.8-1.5% cooking wine, 1-1.5% marinade (containing salt, sugar, chicken powder, garlic powder, spicy marinade), in the preferred version, the core material is made of 84% butterfly shrimp, 1% complex phosphate, 1% guar gum, 2% cornstarch, 10% ice Water, 1% cooking wine, 1% marinade.

[0056] The present embodiment takes butterfly shrimp as an example, and other kinds of whole shrimps can also be processed in the same way.

[0057] Prepare as follows:

[0058] 1. Stir and disperse the compound phosphate, guar gum, corn starch, and marinade, then add cooking wine and ice water for beating, first stir at a low speed of 120r / min for 1min, then stir at a medium speed of 720r / min for 3min;

[0059] 2. Add butterfly shrimp, stir at low speed...

Embodiment 3

[0069] A frozen pre-fried fish and shrimp breaded food, the core material is composed of 50-60% shrimp minced meat, 20-30% tilapia minced meat, 1-2% compound Phosphate, 0.1-0.2% guar gum, 0.1-0.2% compound emulsification thickener, 2.5-4% denatured tapioca starch, 6-10% ice water, 0.6-1% salt, 1- 2% white sugar, 1-2% red onion oil, 0.1-0.3% shrimp paste, 0.2-0.4% water-soluble onion powder, 0.2-0.4% water-soluble black pepper powder, in the preferred version Among them, the core material is composed of 56% minced shrimp, 28% minced tilapia, 1% complex phosphate, 0.1% guar gum, 0.2% compound emulsified thickener, 3% denatured cassava Starch, 7% ice water, 0.8% salt, 1.5% white sugar, 1.6% shallot oil, 0.2% shrimp paste, 0.3% water-soluble onion powder, 0.3% water-soluble black pepper powder become.

[0070] In this embodiment, minced shrimp meat and minced tilapia meat are taken as examples, and other recombined fish and shrimp meat can also be processed in the same way.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com