Cornstalk biochar with capacity of repairing nitrogen and phosphorus non-point source pollution and repairing method

A corn stalk charcoal and corn stalk technology, which is applied in the field of corn stalk biochar and restoration, can solve problems such as pollution sources, and achieve the effects of increasing adsorption performance, repairing nitrogen and phosphorus non-point source pollution, and high-efficiency nitrogen and phosphorus non-point source pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

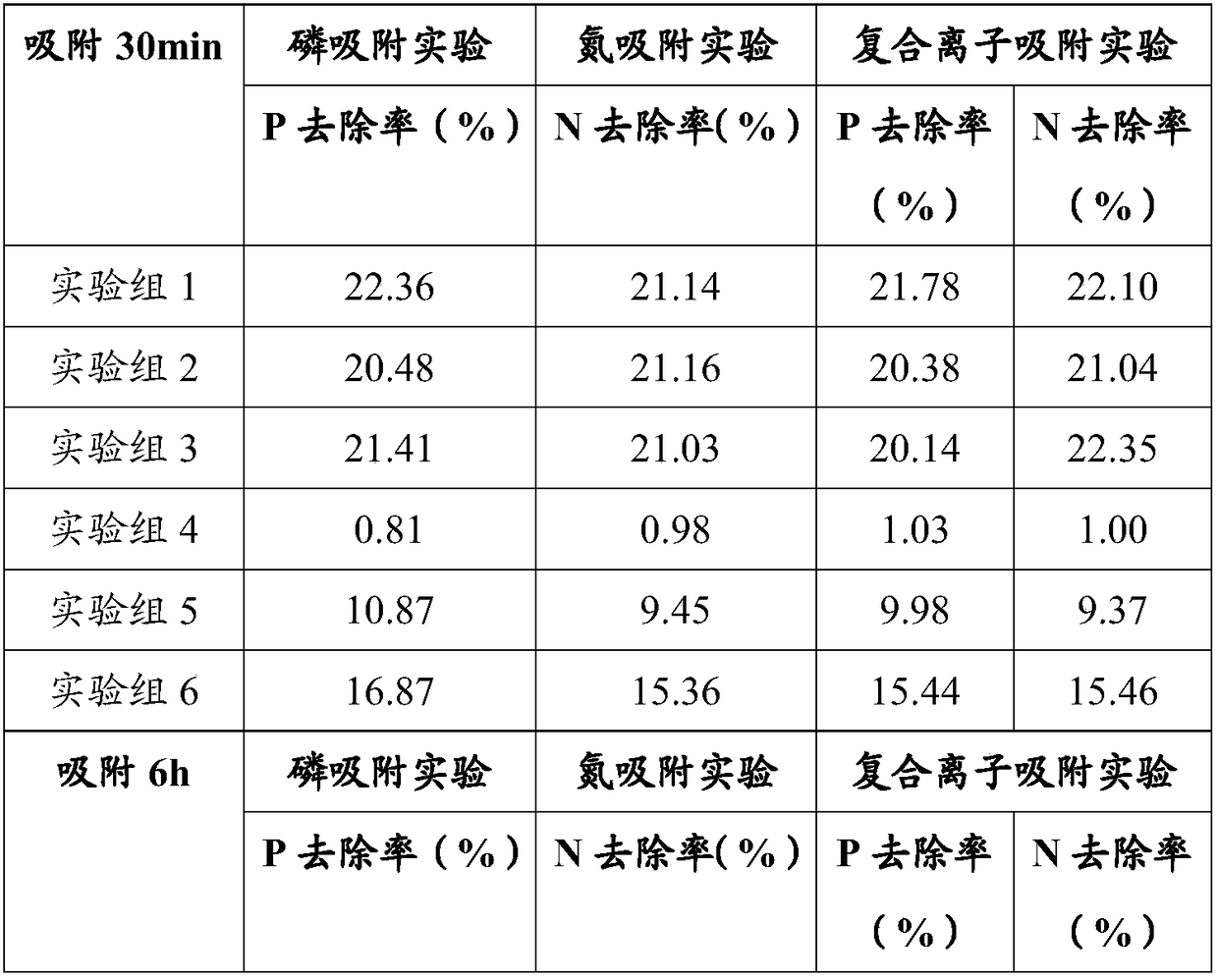

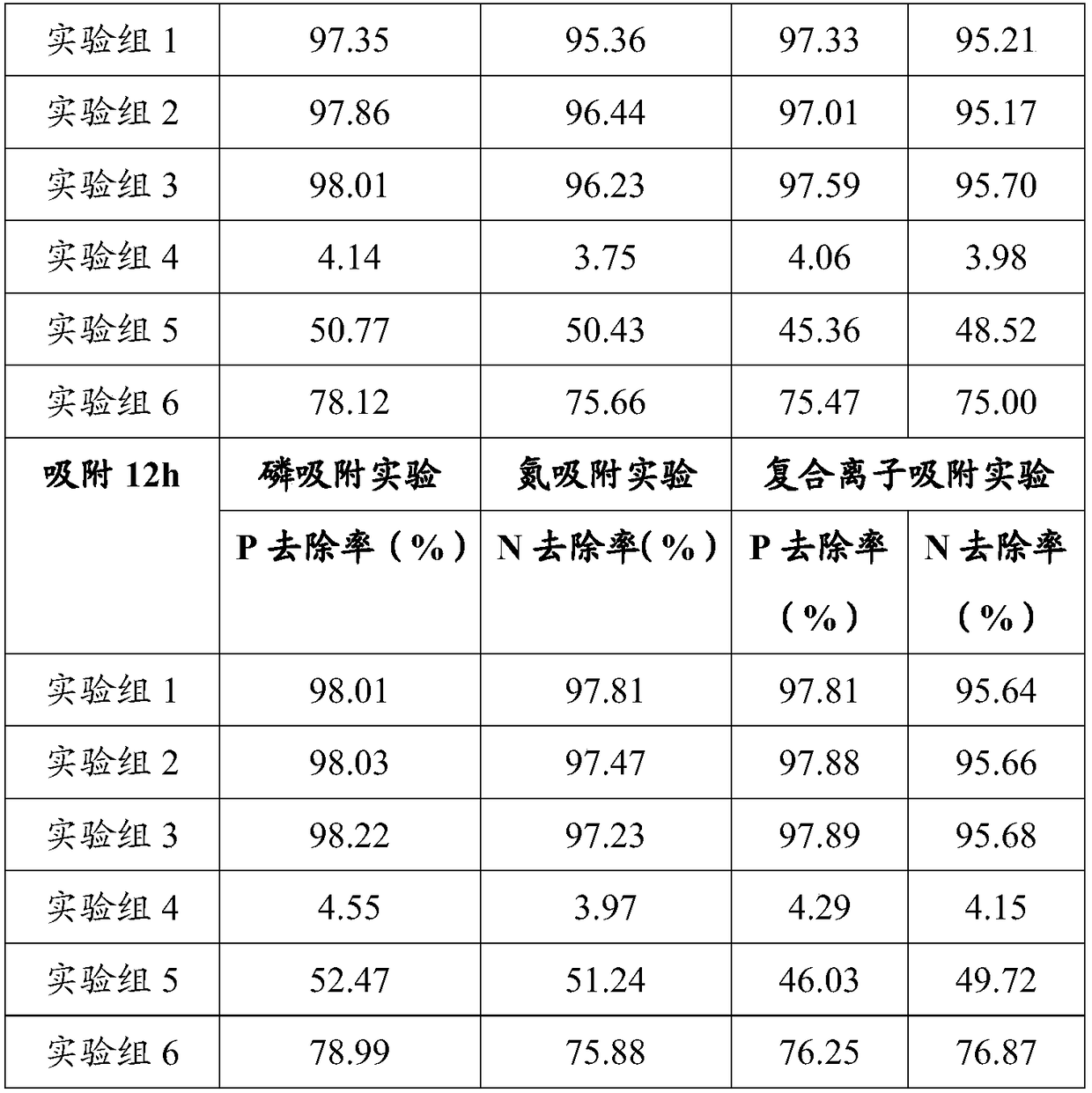

Embodiment 1

[0034] A corn stalk biochar capable of repairing nitrogen and phosphorus non-point source pollution is made of the following raw material components in parts by weight: 50 parts of corn stalk charcoal, 0.1 part of microbial agent; the microbial agent is yeast powder; the Corn stalk charcoal is made according to the following method: crush corn stalks into 1-2 cm straw fragments, add 5% mass fraction of calcium chloride solution to soak for 36 hours, filter and dry at 105°C (moisture content ≤ 10% ) straw fragments, and then carbonized to obtain corn straw charcoal. The carbonization is carried out in a tube furnace, and nitrogen gas is introduced to protect the atmosphere during carbonization. The heating rate is 25°C / min. After reaching 650°C, it is maintained for 1 hour and cooled to room temperature.

[0035] The method for remediating nitrogen and phosphorus non-point source pollution by using corn stalk biochar described in Example 1 may further comprise the steps:

[00...

Embodiment 2

[0043] A kind of corn stalk biochar capable of repairing nitrogen and phosphorus non-point source pollution, made of the following raw material components in parts by weight: 200 parts of corn stalk charcoal, 0.5 part of microbial agent; the microbial agent is a huge Bacillus powder; the corn stalk charcoal is made according to the following method: crush the corn stalks into 1-2 cm straw fragments, add 5% mass fraction of calcium chloride solution to soak for 36 hours, filter and dry at 105°C (moisture content≤10%) straw fragments, and then carbonize to obtain corn straw charcoal. The carbonization is carried out in a tube furnace, and nitrogen gas is introduced to protect the atmosphere during carbonization. The heating rate is 25°C / min. After reaching 650°C, it is maintained for 1 hour and cooled to room temperature.

[0044] The method for remediating nitrogen and phosphorus non-point source pollution by using corn stalk biochar described in Example 2 comprises the followi...

Embodiment 3

[0052] A corn stalk biochar capable of repairing nitrogen and phosphorus non-point source pollution is made of the following raw material components in parts by weight: 100 parts of corn stalk charcoal, 0.2 parts of microbial agent; the microbial agent is yeast powder and has a solution The mixture of Bacillus megaterium powder with phosphorus function in a mass ratio of 1:1; the corn stalk charcoal is made according to the following method: crush corn stalks into 1-2 cm straw fragments, add 5% mass fraction Soak in the calcium chloride solution for 48 hours, filter and dry at 105° C. (moisture content ≤ 10%) straw fragments, and then carbonize to obtain corn straw charcoal. The carbonization is carried out in a tube furnace, and nitrogen gas is introduced to protect the atmosphere during carbonization. The heating rate is 25°C / min. After reaching 650°C, it is maintained for 1 hour and cooled to room temperature.

[0053] The method for remediating nitrogen and phosphorus non-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com