Polyacrylate emulsion capable of postponing dye transfer and preparation method thereof

A technology of polyacrylate emulsion and hydroxyethyl acrylate, which is applied in the field of textile printing and dyeing, can solve the problems of affecting the water resistance of the emulsion film, serious dye migration, and low elongation at break, so as to delay dye migration, reduce solubility, Reduce the effect of migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] For better illustrating the present invention, facilitate understanding technical scheme of the present invention, typical but non-limiting embodiment of the present invention is as follows:

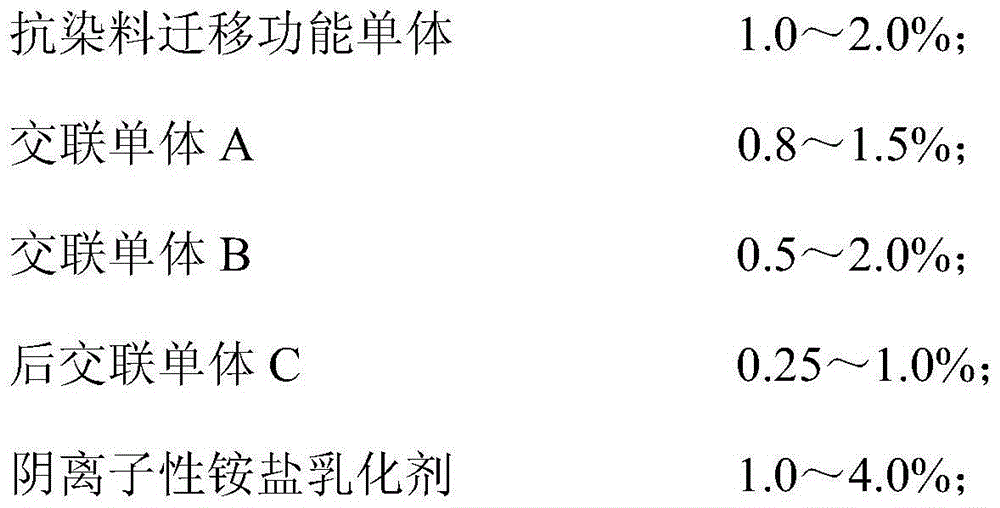

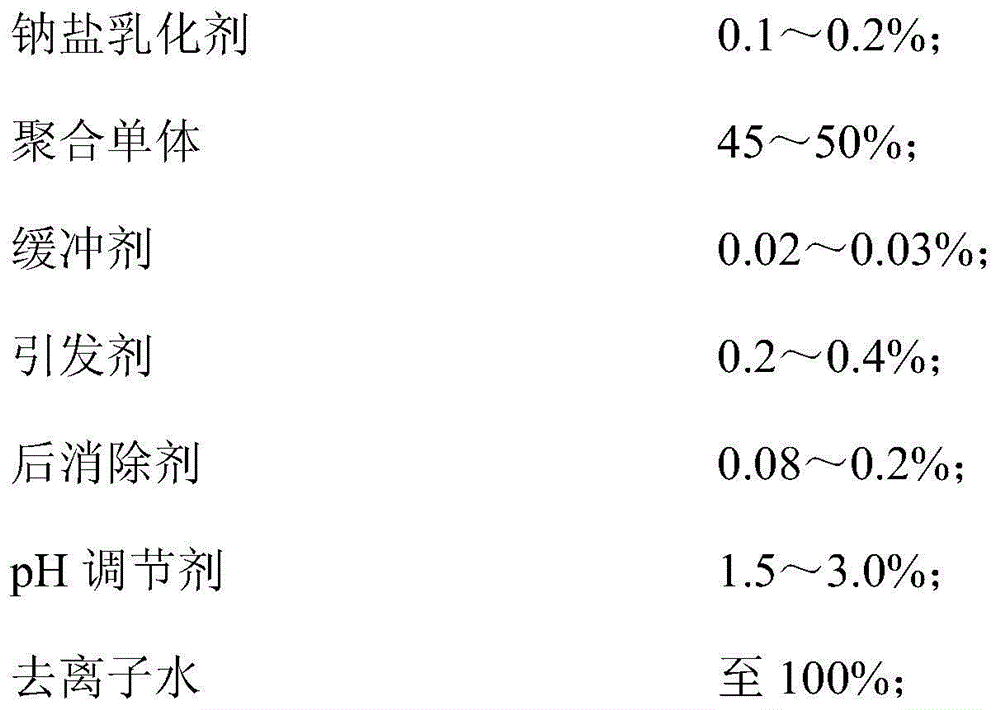

[0053] Embodiments 1 to 4 provide polyacrylate emulsions that delay dye migration, and the specific composition and content are as shown in Table 1:

[0054] The composition of the polyacrylate emulsion that table 1 embodiment 1~4 provides

[0055]

[0056]

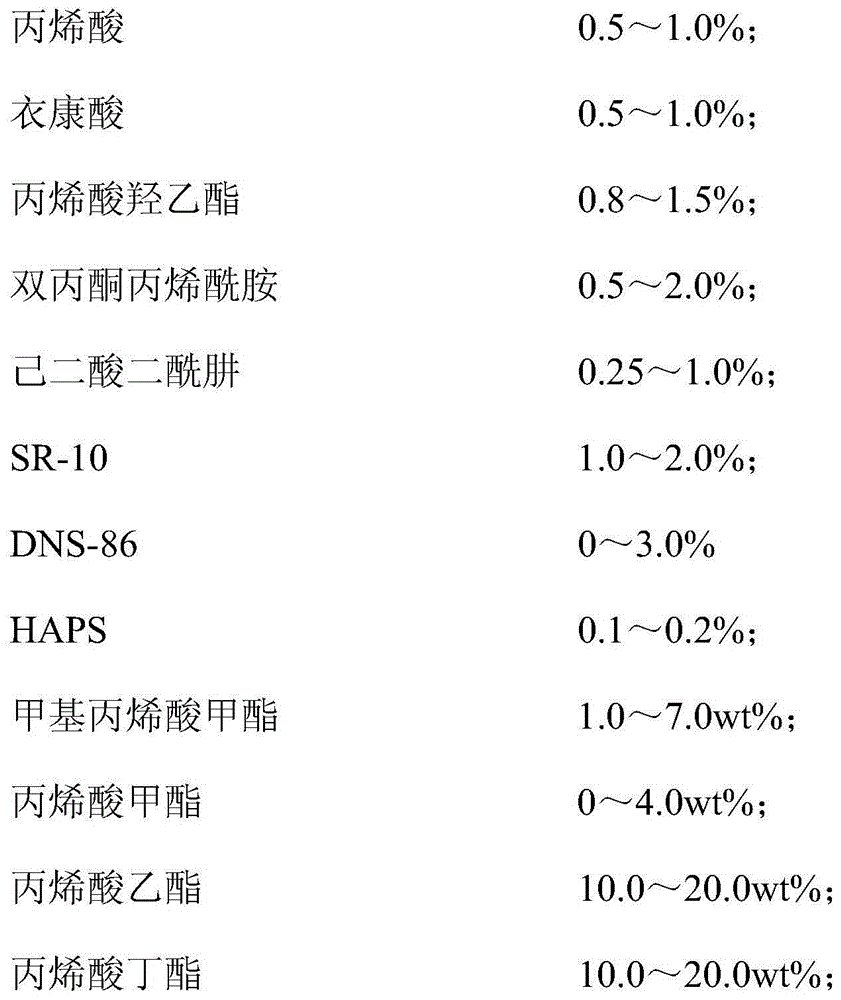

[0057] Comparative Examples 1 to 4 provide comparative examples of polyacrylate emulsions that delay dye migration, and the specific composition and content are shown in Table 2:

[0058] The composition of the polyacrylate emulsion that table 2 comparative example 1~4 provides

[0059]

[0060]

[0061]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com