A kind of bronzing paste and preparation method thereof

A technology of bronzing paste and acrylic emulsion, which is applied in dyeing, textiles and papermaking, and can solve the problems of general water resistance and limited application range of EVA materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A kind of bronzing pulp, described bronzing pulp is mainly prepared by following raw material by weight part array:

[0056]

[0057] The hot-melt powder is polyamide powder; the particle size of the hot-melt powder is 0-80 μm, excluding 0;

[0058] The curing agent is 3-(2,3-epoxypropoxy)propyltrimethoxysilane; the thickener is associative polyurethane; and the defoamer is polysiloxane.

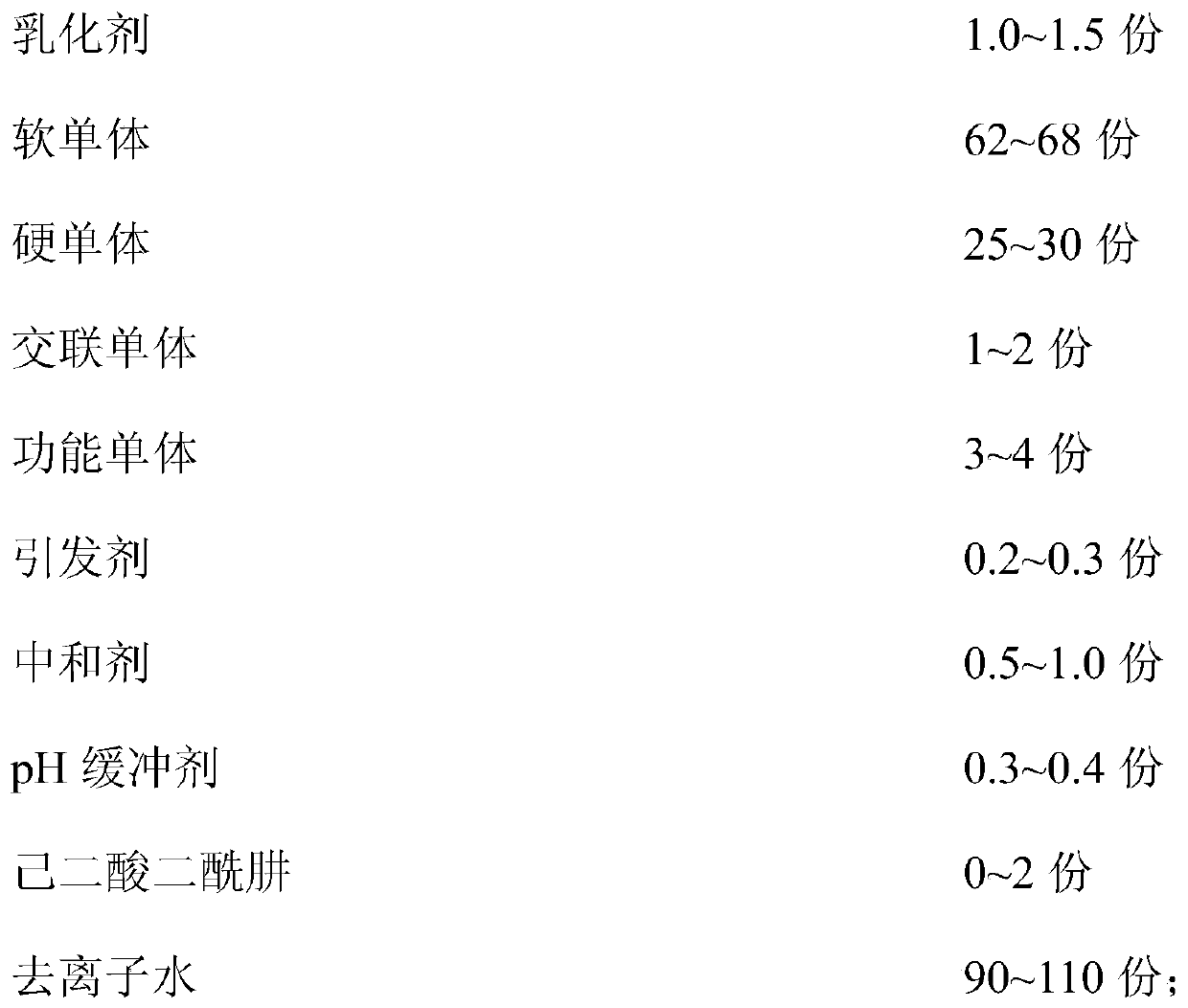

[0059] The acrylic emulsion is mainly prepared from the following raw materials in parts by weight:

[0060]

[0061] The cross-linking monomer is diacetone acrylamide.

[0062] The emulsifier is a phosphate emulsifier and a reactive emulsifier, the phosphate-containing emulsifier is fatty alcohol polyoxyethylene ether phosphate, and the reactive emulsifier has a molecular formula of CH 2 =CHCH 2 OCH 2 CH(ROCH 2 )(OCH 2 CH 2 ) n The surfactant of OX, wherein R is methyl, n is 30, and X is H.

[0063] The functional monomer is an acrylic monomer containing a ring structu...

Embodiment 2

[0075] A kind of bronzing pulp, described bronzing pulp is mainly prepared by following raw material by weight part array:

[0076]

[0077] The hot-melt powder is polyester powder and polyurethane powder; the particle size of the hot-melt powder is 0-80 μm, excluding 0;

[0078] The curing agent is 3-(2,3-epoxypropoxy)propyltrimethoxysilane; the thickener is associative polyurethane; and the defoamer is polysiloxane.

[0079] The acrylic emulsion is mainly prepared from the following raw materials in parts by weight:

[0080]

[0081] The crosslinking monomer is ethyl methacrylate acetoacetate.

[0082] The emulsifier is a phosphate emulsifier and a reactive emulsifier, the phosphate-containing emulsifier is fatty alcohol polyoxyethylene ether phosphate, and the reactive emulsifier has a molecular formula of CH 2 =CHCH 2 OCH 2 CH(ROCH 2 )(OCH 2 CH 2 ) n The surfactant of OX, wherein R is pentyl, n is 10, X is SO 3 NH 4 .

[0083] The functional monomer is an ...

Embodiment 3

[0095] A kind of bronzing pulp, described bronzing pulp is mainly prepared by following raw material by weight part array:

[0096]

[0097] The hot-melt powder is a mixture of polyamide powder, polyester powder and polyurethane powder; the particle size of the hot-melt powder is 0-80 μm, excluding 0;

[0098] The curing agent is 3-(2,3-epoxypropoxy)propyltrimethoxysilane; the thickener is associative polyurethane; and the defoamer is polysiloxane.

[0099] The acrylic emulsion is mainly prepared from the following raw materials in parts by weight:

[0100]

[0101] The cross-linking monomer is diacetone acrylamide.

[0102] The emulsifier is a phosphate emulsifier and a reactive emulsifier, the phosphate-containing emulsifier is fatty alcohol polyoxyethylene ether phosphate, and the reactive emulsifier has a molecular formula of CH 2 =CHCH 2 OCH 2 CH(ROCH 2 )(OCH 2 CH 2 ) n The surfactant of OX, wherein R is an alkyl group, n is 15, and X is H.

[0103] The fun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com