Inductance and ultrasound coupling-assisted method for direct laser deposition of metal material

A laser deposition and ultrasonic coupling technology, applied in the field of additive manufacturing, can solve the problems of inability to stir the molten pool, low heating efficiency, complex structure, etc., and achieve the effects of reducing micro and macro cracks, reducing pores, and prolonging the action time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

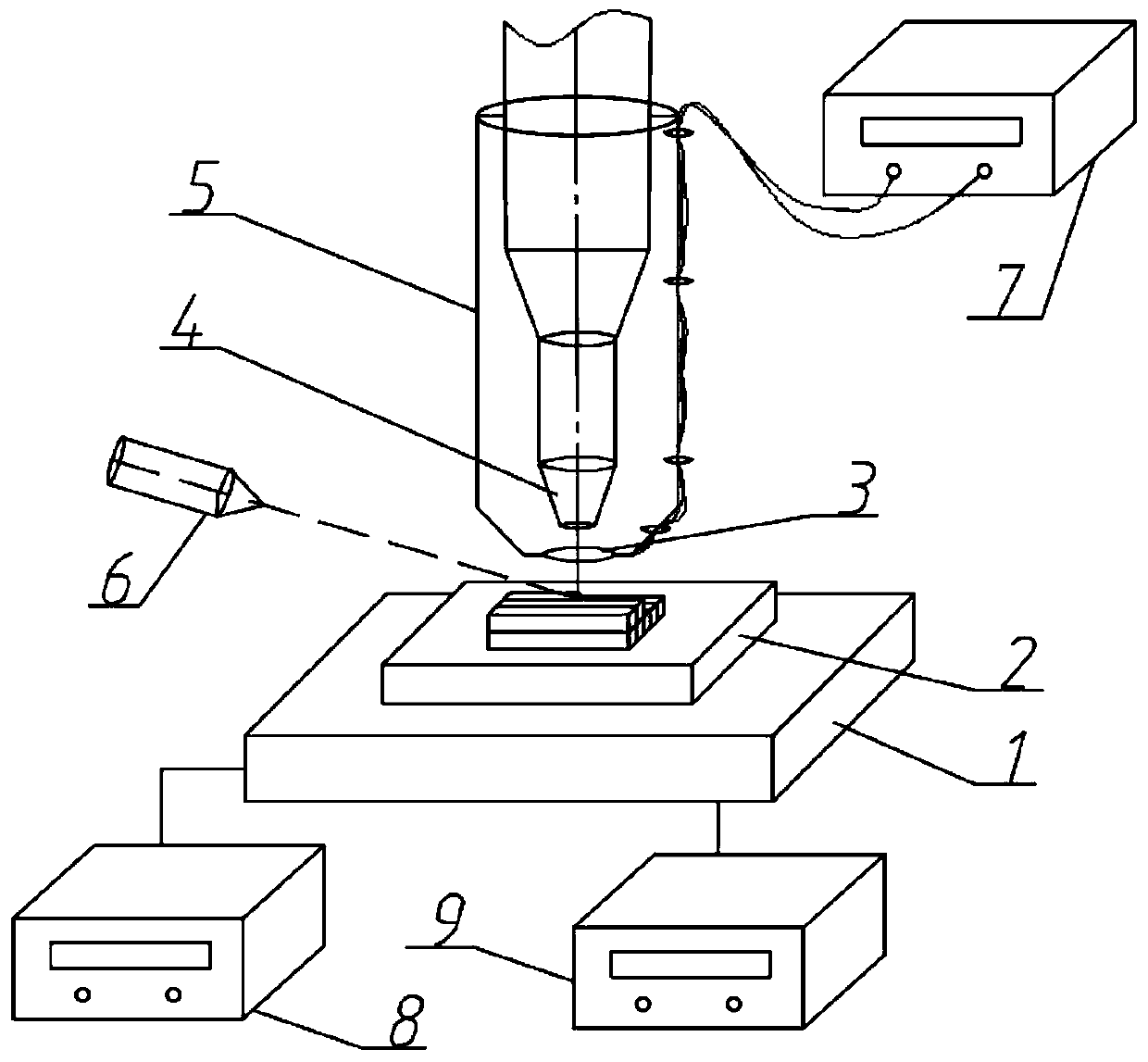

[0024] An example of direct laser deposition of metal materials assisted by inductive ultrasonic coupling is given below in combination with the above-mentioned method. The selected materials are titanium alloy (TC4) and nickel-based superalloy (Inconel718) spherical powder. The specific steps of the forming process are as follows:

[0025] Step 1: Preparations

[0026]Mix the spherical TC4 and Inconel718 metal powders with a particle size of 40-90 μm in the experiment according to the mass fraction of 7:3, put them in a drying oven and dry them at 120°C for 4 hours, and pour the dried powder into the powder feeder; The TC4 substrate 2 used was polished with sandpaper to remove the oxide layer, then cleaned with acetone, ethanol and deionized water in sequence, and dried after cleaning; the ultrasonic inductor auxiliary device was installed as shown in the figure, and the ultrasonic platform 1 was fixed on the machine tool table. 2. Fix it on the ultrasonic platform 1. After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com