Silicon-carbon negative electrode material and preparation method thereof

A negative electrode material, silicon carbon technology, applied in the field of materials, can solve the problems affecting the capacity of silicon-based materials, hindering the insertion of lithium ions and nano-silicon-based materials, and achieving the effect of reducing the hindrance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

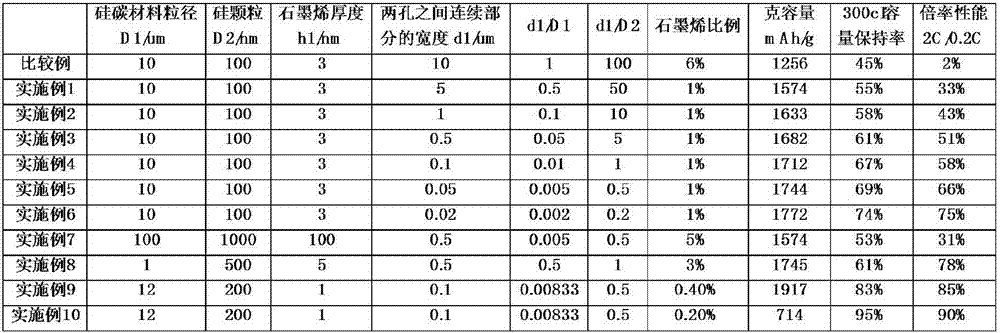

Examples

Embodiment 1

[0032] Embodiment 1 differs from Comparative Example 1 in that the present embodiment comprises the following steps:

[0033] Step 1, select the silicon particle that particle diameter is 100nm, sheet thickness is 3nm, the porous graphene sheet layer that sheet plane diameter is 50 μ m is conductive agent component (mass ratio between silicon particle and graphene is 99:1 ); the hole diameter of the porous graphene is 1 μm, and the width d1 of the continuous part between the two holes is about 5 μm;

[0034] Others are the same as those of Comparative Example 1 and will not be repeated here.

Embodiment 2

[0035] Embodiment 2 is different from Embodiment 1 in that this embodiment includes the following steps:

[0036] Step 1, select the silicon particle that particle diameter is 100nm, sheet thickness is 3nm, the porous graphene sheet layer that sheet plane diameter is 50 μ m is conductive agent component (mass ratio between silicon particle and graphene is 99:1 ); the hole diameter of the porous graphene is 1 μm, and the width d1 of the continuous part between the two holes is about 1 μm;

[0037] Others are the same as in Example 1, and will not be repeated here.

Embodiment 3

[0038] Embodiment 3 is different from Embodiment 1 in that this embodiment includes the following steps:

[0039] Step 1, select the silicon particle that particle diameter is 100nm, sheet thickness is 3nm, the porous graphene sheet layer that sheet plane diameter is 50 μ m is conductive agent component (mass ratio between silicon particle and graphene is 99:1 ); the hole diameter of the porous graphene is 1 μm, and the width d1 of the continuous part between the two holes is about 0.5 μm;

[0040] Others are the same as in Example 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Sheet thickness | aaaaa | aaaaa |

| Layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com