High-performance lithium ion battery cathode material and preparation method thereof

A technology for lithium ion batteries and positive electrode materials, applied in electrode manufacturing, battery electrodes, circuits, etc., can solve the problems affecting the electrochemical performance of the electrode compaction density battery, the poor contact between the material and the binder conductive agent, and the unsatisfactory positive electrode material. Use requirements and other issues to achieve the effect of improving electrode processing performance, improving energy density and high power output performance, and improving electrode processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 50 kg of nickel-cobalt and manganese composite oxide precursor (Ni: Co: Mn = 0.35: 0.3: 0.35) and 26 kg of Li 2 CO 3 Thoroughly grind and mix, then pre-sinter at 450°C for 5 hours, then heat up to 950°C for 24 hours at high temperature, and finally cool to room temperature.

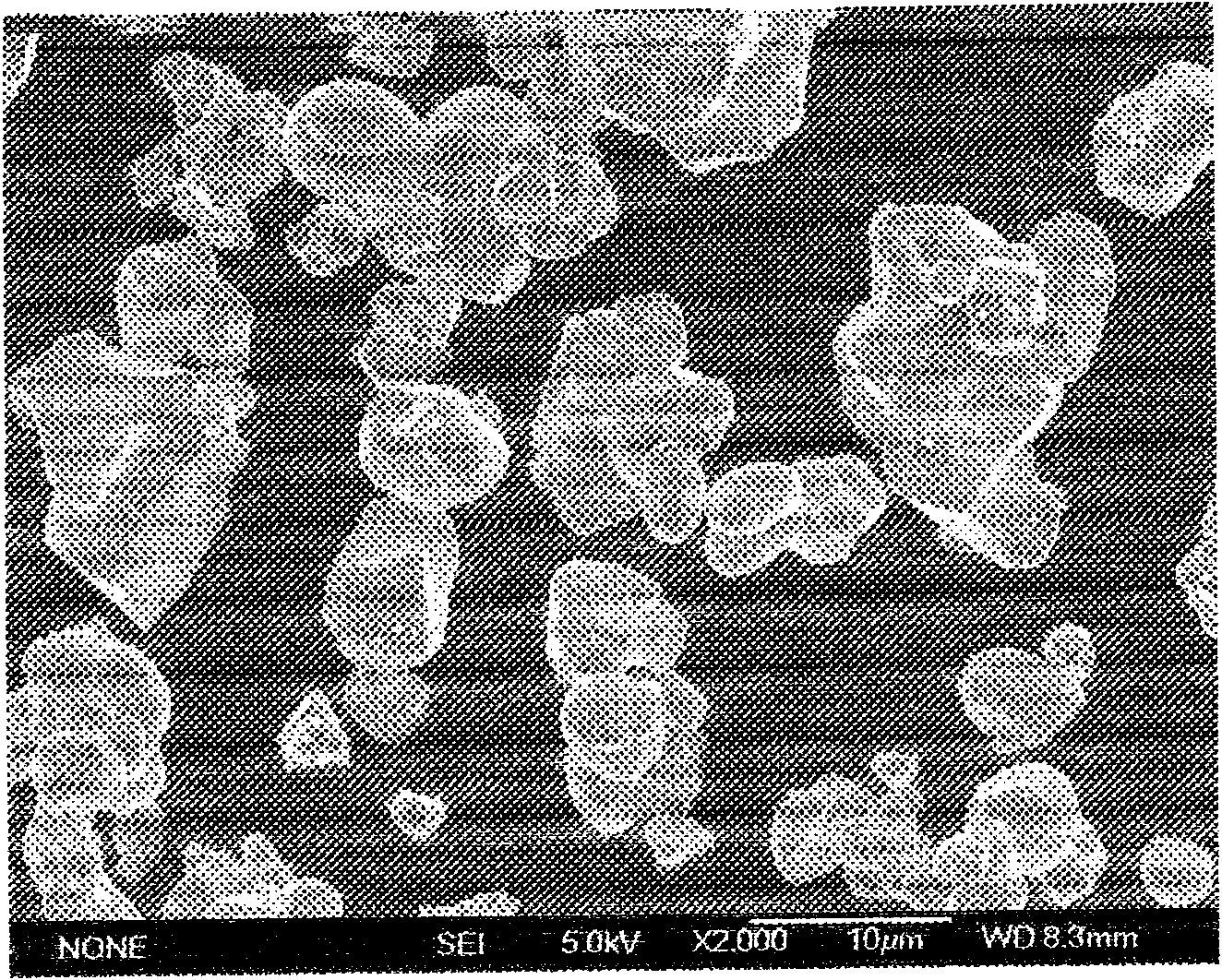

[0029]The particle size and morphology of the materials were observed on a Hitachi S-4000 scanning electron microscope. from figure 1 We can find that the new LiNi we prepared 0.35 co 0.3 mn 0.35 o 2 It is a single crystal particle, the average grain size is about 5-10 microns, the particle size is uniform, and the surface is smooth.

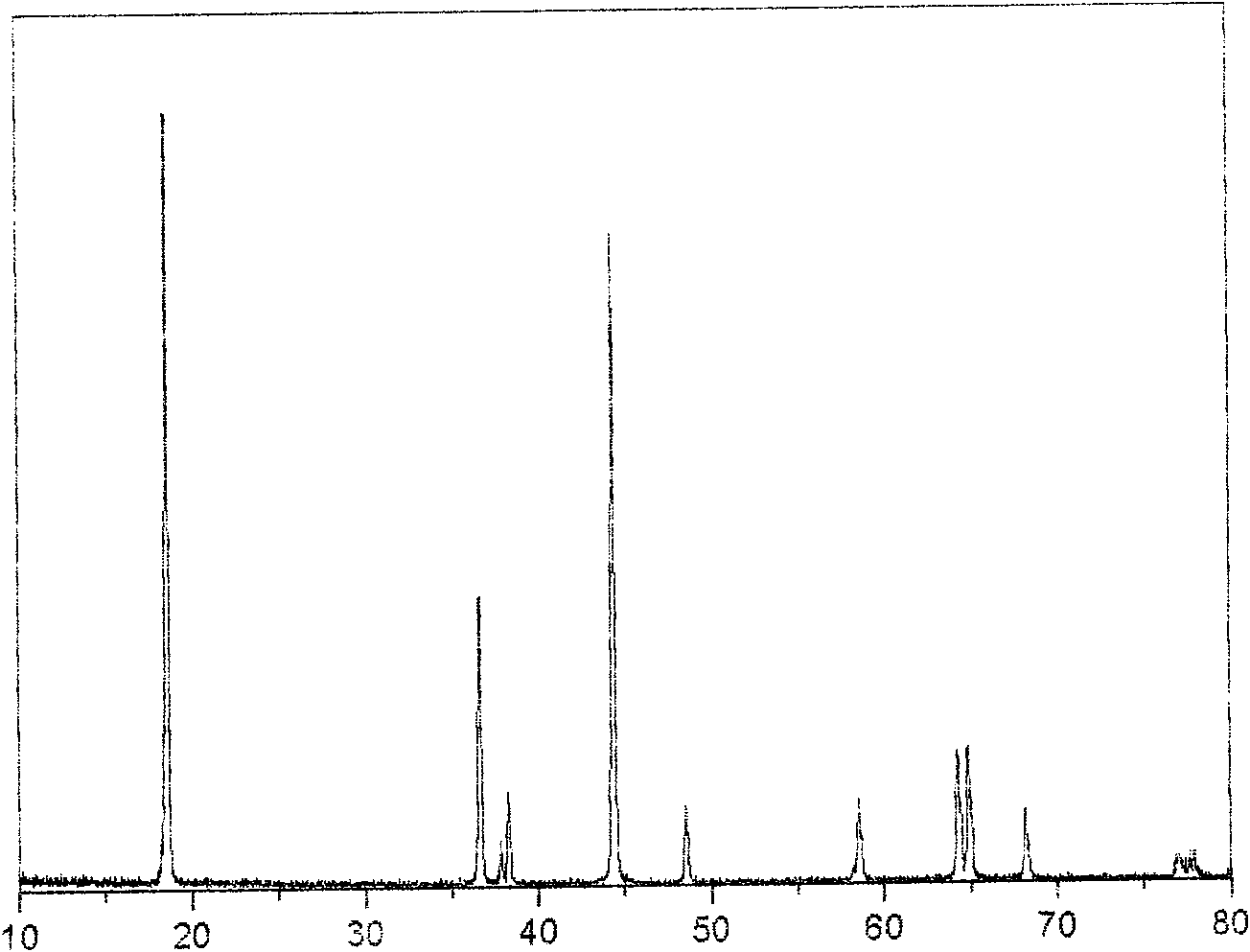

[0030] The crystal structure of the material was analyzed using a Rigaku B / Max-2400 X-ray diffractometer (Rigaku Ltd.), with Cu Kα line as the light source, and the diffraction angle 2θ ranged from 10° to 90°. from figure 2 We can find that the synthesized material has a standard layered structure and no impurity phase exists.

[0031] Using the BET method ...

Embodiment 2~10

[0036] Synthesize a series of layered structure LiNi under different conditions by the preparation method of the present invention x co y m 1-x-y o 2 positive active material

[0037] According to the preparation method provided by the invention, under the different conditions listed in table 1, a series of layered structure LiNi x co y m 1-x-y o 2 Positive active material.

[0038] Table 1

[0039] Example

Embodiment 11

[0041] Mix 50 kg of nickel-cobalt-manganese-aluminum composite hydroxide precursors with 27.4 kg of lithium hydroxide, then fully ball mill, then pre-sinter at 400 degrees for 8 hours, then heat up to 850 degrees for high-temperature sintering for 24 hours, and finally cool At room temperature, the required lithium-ion battery-containing nickel-cobalt layered structure positive electrode active material is synthesized.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com